What is a dynamic positioning (DP) system?

Key Highlights

- DP systems use sensors, control algorithms and thrusters to keep vessels precisely positioned, even in rough seas and deep waters where anchoring is impractical.

- There are three classes of DP systems, each offering increasing levels of redundancy and fault tolerance for critical offshore activities.

- Applications include offshore drilling, subsea construction, pipeline installation and renewable energy projects.

- Benefits of DP include high precision, increased operational efficiency and the ability to operate in deeper waters, while challenges involve high costs, maintenance and sensor reliability.

Editor’s note: Welcome to Offshore’s new educational “What Is…?” series. If you’re interested in contributing your insights and sharing industry knowledge with the next generation of offshore professionals, contact Chief Editor Ariana Hurtado at [email protected] for more information.

By Matthew Gagnebin, Noble Corp.

Dynamic positioning (DP) is a computer-controlled system that automatically maintains a vessel’s position and heading using thrusters. Unlike traditional anchoring/mooring, DP allows ships and mobile offshore drilling units (MODU) to stay precisely in place, even in deep water where anchoring is impossible. This technology is vital for offshore drilling, subsea construction and other operations that require pinpoint accuracy. DP systems are commonly seen on MODUs (e.g., drillships, semisubmersibles), subsea construction vessels and specialized vessels like cable layers and research ships.

How does a DP system work?

To maintain position, DP uses a combination of position reference and vessel reference sensors, power generation and thrusters, and advanced control algorithms to counteract environmental forces such as wind, waves and currents.

In a nutshell: Think of DP as an autopilot for ships, but instead of moving forward, it keeps the vessel perfectly still, even in rough seas.

Here’s how it works:

- Sensors measure position, heading and environmental conditions using GPS, gyros and wind sensors.

- Control computers process this data and calculate the necessary thrust adjustments to maintain a fixed position.

- Power generation and thrusters respond instantly to a computer-calculated model generating power/thrust in the correct direction to maintain position and heading.

The main components of the system are position reference systems (e.g., GPS and acoustic beacons), environmental sensors (e.g., wind anemometers, motion sensors and current meters), power and thruster systems (e.g., diesel electric power plant and Azimuth thrusters), and control system (i.e., the “brain” that integrates all inputs and commands the thrusters).

How is a DP system maintained?

Regular testing of sensors, thrusters and control systems, plus crew training, ensures reliability.

What are the types of DP systems?

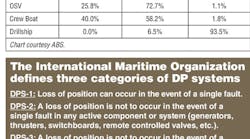

DP systems are classified as Class 1, 2, and 3 based on ability to maintain position under intact or single fault condition (redundancy):

- DP Class 1 is a basic system with no redundancy;

- DP Class 2 offers redundant components for fault tolerance; and

- DP Class 3 has full redundancy, including fire and flood protection, and is used in critical operations like drilling.

What are real-world applications for DP systems?

Dynamic positioning is essential in the offshore energy sector.

A DP system keeps rigs stable over wellheads during offshore drilling operations, and it also enables precise placement of pipelines and structures during subsea construction.

For renewable energy projects, the system positions vessels for subsea cable installation and offshore wind farms.

In addition, a DP system on research and survey vessels maintains the exact location for scientific measurements.

DP is especially critical in deepwater regions like the Gulf of Mexico, Brazil and West Africa, where anchoring is impractical.

What are the benefits and challenges?

A DP system provides precision as it maintains position within a few meters. Other advantages include an increase in efficiency by eliminating time-consuming anchoring/mooring and enhanced operability with its ability to work in deeper water.

On the other hand, challenges include costs, complexity and failure risks. A DP system requires a high initial investment and continuous maintenance expenses as well as skilled operators and robust training. In addition, power loss or sensor errors can compromise positioning.

What are the safety considerations?

Redundancy, emergency procedures and power management are critical to prevent loss of position.

Why is DP important in offshore operations?

Dynamic positioning (DP) is essential for offshore drilling, providing precise station-keeping over wellheads in deepwater environments where traditional anchoring is not feasible.

The enhanced redundancy of Class 2 and Class 3 DP systems, standard requirements for offshore drilling MODUs, ensures safe operations near subsea infrastructure, mitigating risk and maintaining operational integrity. By eliminating time-intensive mooring, DP significantly improves efficiency and enables complex activities such as subsea construction and ROV interventions.

Modern DP technology is advancing through real-time data integration, automation, hybrid power solutions and AI-driven optimization—aligning with the industry’s commitment to safety, sustainability and performance excellence.

To support these complex operations, rigorous and structured training programs are mandatory for all DP personnel. These programs combine theoretical instruction with practical simulator-based exercises, ensuring operators can manage normal operations as well as emergency scenarios such as power loss or thruster failure. Initial training and certification through bodies such the Nautical Institute enforce global standards, guaranteeing that DP operators possess the technical knowledge, situational awareness and decision-making skills required to maintain safety and operational integrity in high-risk offshore environments.

Want more content on DP systems?

Offshore's "What Is...?" series

Young professionals in the offshore energy industry often encounter technical terms and acronyms that seasoned subject matter experts (SMEs) know by heart—but aren’t always clear to the next generation. Offshore’s new “What Is…?” educational series aims to bridge that gap by providing concise, practical explainers for emerging professionals.

Some of the most-searched topics include:

- What is an FPSO?

- What is a dynamic positioning (DP) system?

- What is an SOV?

- What is directional drilling?

- What is a subsea production system?

- What is a blowout preventer (BOP)?

- What is a subsea tree (christmas tree)?

- What is an offshore riser system?

- What is a jackup rig?

- What is a subsea tieback?

If there’s an offshore energy subject you’d like to highlight in a brief explainer article (600-1,200 words), reach out to Chief Editor Ariana Hurtado at [email protected] for more information.

About the Author

Matthew Gagnebin

Matthew Gagnebin serves as senior manager of dynamic positioning in Noble’s Operational Integrity organization, where he leads the company’s DP Governance Group to elevate standards, competency and operational support across a global fleet.

His 25‑year maritime journey spans blue‑water navigation, offshore oil and gas operations, and DP systems leadership.

After graduating from Texas Maritime Academy with a 3rd Mate Unlimited deck license, Gagnebin launched his offshore career on survey vessels in the South Pacific, then advanced to captaining offshore supply vessels. He later transitioned to drillships in the Gulf of Mexico as DPO, working on DP3 units then supporting DP system commissioning during newbuild programs.

In 2019, Gagnebin moved shoreside with Noble as marine simulation and training manager, building integrated training and competency pathways. He then advanced into operational roles as DP superintendent and senior manager developing the DP Governance Group to be first choice focused on incident‑free DP operations, barrier management and continuous improvement across operational station‑keeping, DP trials and marine training.