Shell outlines plans for North Sea Jackdaw gas project

Offshore staff

LONDON – Shell has submitted an environmental statement for its planned development of the Jackdaw gas/condensate field in the UK central North Sea.

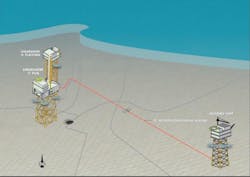

The ultra-high-pressure/high-temperature field is in blocks 30/02a, 30/02d, and 30/03a in a water depth of around 78 m (256 ft), 30 km (18.6 mi) southeast of Shell’s Shearwater platform and close to the UK/Norway median line.

Shell and co-venturer ONE-Dyas E&P propose a not permanently attended wellhead platform (WHP) tied back via a 31-km (19-mi) subsea pipeline to the Shearwater platform.

BG discovered Jackdaw in 2005, appraising the field between 2007 and 2012.

The development will increase the lifespan of the Shearwater facilities and onshore infrastructure at St Fergus, and support wider electrification efforts the industry is working on in this part of the North Sea.

The WHP will comprise a four-legged steel jacket supporting a topsides module. It is designed to be monitored and controlled from Shearwater via the WHP Integrated Control and Safety System (ICSS), with signals transmitted directly to the host via a microwave telemetry system.

Visits to the platform, (six to nine per year), will be scheduled primarily for chemical and fuel re-supply, well interventions, and maintenance. The WHP will have accommodation for up to 30 people with a helideck as the main means of access, potentially with walk-to-work platforms during larger work campaigns.

The well bay will be able to house up to nine wellheads / Xmas trees, although only four wells will be drilled initially. Corrosion resistant alloy materials will be applied for all process piping on the platform to mitigate the corrosive effects of CO2 (4.2%) and H2S (30 ppmv) in the produced fluids.

Jackdaw’s four wells will be drilled using a heavy-duty jackup positioned over the jacket. Produced fluids will be commingled topsides and exported to Shearwater via the new 12-in. nominal bore trenched and buried pipeline, with a maximum external diameter of 18-in.

The pipeline and subsea infrastructure will be lined/clad with corrosion resistant alloy material to provide protection against the corrosive effects of the fluids. All processing of the fluids will take place at Shearwater including separation, treatment, and discharge of produced water.

Although no continuous flaring is planned for the development, access to the Shearwater flare will be needed so that the Jackdaw production pipeline can be depressurized to avoid hydrate formation build-up after a long-term shutdown and during commissioning or an unplanned cold start-up.

Shell also plans modifications at the Shearwater A wellhead platform including a new 14-in. riser and riser emergency shutdown valve, plus a blowdown module at the inlet facilities downstream of the riser; and modifications at the Shearwater C process, utilities and quarters platform to the acid gas removal unit to manage removal of CO2 and H2S from Jackdaw fluids.

05/13/2021