Sea Launch back on track; real thing scheduled this fall

After being delayed over technology transfer concerns by the US government, the international Sea Launch project successfully launched a demonstration payload earlier this year. The launch marked the first of its kind from a floating platform at sea. The demonstration payload achieved a geostationary transfer orbit.

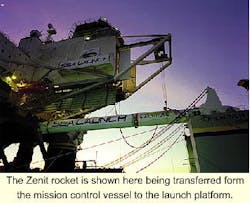

Sea Launch is a joint project combining technology and hardware from Norway, US, and Russia. The project provides a unique venue for the launch of commercial payloads into space, using a converted semisubmersible as a platform and a newbuild ship as mission control. Sea Launch fires rockets from a dynamically positioned (DP) location on the equator in the middle of the Pacific Ocean. The Sea Launch Commander vessel is capable of carrying three Zenit rockets and has payload assembly and preparation facilities on board. The rocket payload is assembled on the mission control ship, and then the rocket is transferred to the semisubmersible, which is partially submerged for stability. Kongsberg Simrad, the company responsible for the DP system, said the rocket is very sensitive to pitch and roll prior to launch. If the platform were to roll as little as 1.2°degrees, the rocket could tip and explode.

There was some concern during the engineering phase of the project that the rocket launch might damage the semisubmersible. Assessments after the launch showed only minor damage in the form of broken light bulbs. Logged data showed that the force of the launch caused the platform to dip 4.3?, bow down. The flight to orbit took about one hour and went as planned, according to reports. Sea Launch spokesman Terrance Scott said the company's first commercial payload will be launched sometime in late August or early September.

Glomar Explorer elevator accident update

Last September the riser elevator on the Glomar Explorer deepwater drillship dropped unexpectedly 30 ft while two workers were standing on it. Both workers were injured in the incident. A survey conducted by Matthew-Daniels immediately following the accident last fall found the cause was human error and not a failure in the braking system as Offshore first reported.

According to a report written by Woody Hawkins, who conducted the survey for Matthew-Daniels on behalf of Global Marine, "The integral brake is designed to release when hydraulic pressure is present to operate the hydraulic gear propulsion system that powers the riser elevator assembly. With the ball valve closed, the brakes, upon sensing the pressure release in the riser elevator assembly, fell into the riser hole. We consider this to be the cause of the incident - human error."

Petronius project back on line

Texaco has signed a letter of intent with Gulf Island Fabrication that could be the first step toward getting the Petronius project back on line. Fred Palmer with Texaco confirmed the company has signed an agreement for the fabrication of a new module to replace the one dropped by J. Ray McDermott's heavy lift vessel DB-50 late last year. Gulf Island began work on the replacement in January, including ordering of materials and preliminary fabrication, although Palmer said the final terms of an actual contract are still being discussed. Texaco spokesman Pierre DeGruy said the frame of the new south module is beginning to take shape at the yard in Houma, Louisiana.

Gulf Island constructed the original module, which weighed 3,800 tons and contained processing equipment and crew quarters. This module now rests on the seafloor in 1,800 ft of water near the Petronius site. Texaco has decided not to attempt to retrieve the $70 million module, which industry insiders say was likely reduced to scrap by the impact with the seafloor and deepwater pressure. Palmer said there have been ongoing discussions with the US Minerals Management Service that determined the lost module poses no navigational or environmental risk.

Gulf Island plans to have the replacement module ready some time in the second quarter of 2000. At present, Petronius has only one module installed. Originally the project, in Vioska Knoll 786 of the Gulf of Mexico, was scheduled for first production in late 1998. Palmer said he could not yet commit to a new date for first oil.

A jewel of a nodule

Syntactic foam is an expensive solution for providing buoyancy in deepwater. Small, glass microsphere nodules and gumball-size macrospheres are mixed in with a foam resin creating a lightweight buoyant material that will stand up to the punishing pressures of deepwater. These materials are used in a variety of applications, from supporting cantilever mooring lines to supporting risers.

One area of focus, where syntactic foam is a common application, is fixed buoyancy for remotely operated vehicles (ROVs). These vehicles are used for transportation, intervention, pipelay, and other deepwater applications. As drilling, completion, and pipelay work moves further off the shelf, there is a need for more powerful ROVs that can carry heavier work packages into deeper water. This means more foam of a greater depth tolerance to offset the weight of these larger equipment skids.

The problem with this approach is twofold: The foam becomes more expensive as the depth requirements increase. In addition, as the weight requirements grow, the size of the foam block becomes bulky. On a deepwater or ultra-deepwater rig, space and weight are major cost considerations. Therefore, there is a market for an ROV that can go deeper, carry more weight, and stay longer with same footprint on the vessel deck.

One technology Sonsub is using to address the buoyancy and space considerations, as well as the cost issue, is a newly designed lightweight hollow aluminum sphere. This technology works in conjunction with traditional syntactic foam to provide greater buoyancy in deepwater with the same footprint and, beyond a certain depth threshold, a lower cost. Designed by the Southwest Research Institute under contract with Sonsub parent Saipem, these spheres may find their way into a variety of new designs.

The design is relatively simple in appearance. The spheres measure 9.5-in. in diameter. They are made from a high-strength aerospace forging alloy. The two hemispheres that make up the sphere are forged separately and connected using epoxy glue. They are placed inside a buoyancy block, which is then filled with syntactic foam. The resin in the foam bonds with the spheres to form a resilient system that can withstand pressures up to 6,000 psi. According to Edward Patton of the institute, the new system becomes economically superior to syntactic foam at a water depth of 1,500 meters. The system is being used on Sonsub's new Innovator ROV.