Bureau Veritas opens 3D inspection tool to wider market following successful trial on FPSO

Bureau Veritas Marine & Offshore (BV) has released its Augmented Surveyor 3D (AGS 3D) tool powered by artificial intelligence (AI) and machine learning.

It is designed to help optimize detection and localization of anomalies during offshore structure and vessel inspections.

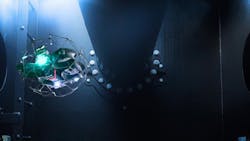

BV has already completed a successful pilot with TotalEnergies on an FPSO offshore West Africa, during which a drone-based inspection took place of two water ballast tanks.

The survey used AGS 3D to process the data, subsequently generating a 3D digital model with AI-supported corrosion analytics.

BV claims its system leads to improved safety and efficiency through automating anomaly detection, corrosion mapping, 3D modeling and other tasks. TotalEnergies is now looking to extend the solution to some of its other facilities and assets.

Typically, BV explained, drone-based surveys generate large volumes of data, including images, videos, and light detection and ranging (LiDAR) scans. Processing these is often time-consuming and resource-intensive. AGS 3D automatically detects anomalies in images and videos captured by drones, and it maps them onto a 3D digital model generated from point cloud data collected by a LiDAR sensor mounted on the drone.

This allows a more streamlined approach to inspections, BV claimed, with less exposure of staff to confined spaces. And through more precise defect localization, maintenance teams can derive actionable insights more quickly.

Potential offshore applications include FPSOs, FSOs and floating offshore wind structures.

AGS 3D provides 360-degree visualization, also offering inspection teams optimized maintenance planning and data-driven decision-making, the company added. This can be especially beneficial as a complement to classification surveys.

Technicians can process and review the results of LiDAR-based drone inspections, AI-driven corrosion detection, automatic defect localization and a unified 3D dataset to issue recommendations.

Clients then receive a final report, data analytics and a 3D model of the asset inspected showing all detected defects. These can also be accessed via BV’s AGS Viewport platform for more in-depth data analysis.