Compressor and turbine washing specialist Gas Turbine Efficiency (GTE) has undergone expansion over the last couple of years, broadening its product range and strengthening its presence around the world.

The company, based in Stockholm but registered in the UK and listed on the London Stock Exchange, is now strongly represented in the US, through sales offices and newly acquired subsidiaries. It has also opened branches in Singapore and in St. Petersburg, the latter tackling opportunities in the Russian oil and gas market. This is the country with the highest number of gas turbines in operation, according to sales manager Per Andersson.

The company has also established itself in Abu Dhabi, where it recently delivered a turbine washing system to an Adma Opco-operated offshore platform.

GTE has long-term agreements with turbine vendors that include Caterpillar/Solar, Rolls Royce, and Siemens. Under these agreements, the vendors recommend the GTE washing system to their turbine customers as part of their after-sales service.

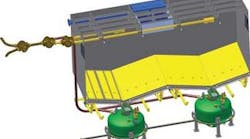

While most sales to offshore customers are for existing turbines, GTE recently clinched a sale to a development project in the Norwegian sector. The delivery, due this summer, comprises one washing unit and nozzle kits for four turbines.

What is particularly interesting about this order is that it includes an online washing system, says Andersson. A daily online wash keeps the turbine operating more efficiently and allows the interval between “conventional” offline washing to be lengthened. The online washing system is fully automated, requiring only a button to be pressed by a control-room operator to start it.

Operators have much to gain from ensuring efficient running of their gas turbines. The benefits of offline washing, according to GTE, include 2% improved availability, 3% improved performance, and 1% improved heat rate the efficiency of fuel consumption. Although these percentages look small, they translate into significant tangible financial gains given current fuel costs.

In the Norwegian sector more efficient turbine operations also mean reduced carbon dioxide emissions and hence lower CO2 tax. Not surprisingly, StatoilHydro is GTE’s leading Norwegian offshore customer.

For more information contact Per Andersson, Gas Turbine Efficiency, Tel +46 8546 10 507, fax +46 8546 10 501,[email protected], www.gtefficiency.com