AIS insulation chosen for Al-Shaheen expansion project platform

AIS is providing insulation materials for the Ruya project (Al-Shaheen Phase 3 – Batch 1) expansion program offshore Qatar, led by North Oil Co.

This involves adding new platforms, pipelines and other infrastructure to lift the production plateau to 300,000 bbl/d.

AIS has a contract to protect the platforms and other infrastructure components, including the BJ platform. This will process oil, gas and utilities from the BH platform, which will receive production from nine new wellhead platforms to be installed under the Ruya workscope, as well as flare gas received from BH before transferring it to the BK flare system.

The BJ topsides, with four main decks and a lower drain and mezzanine deck, will house equipment including dual-fuel turbo generators, gas turbo compressors, heaters, coolers, a triethylene glycol (TEG) regeneration package, phase separators, and export pumps, along with an overhead crane, HVAC systems, and open and closed drain systems.

Hyundai Heavy Industries is constructing the BJ platform at Ulsan, South Korea, with AIS due to supply all materials by May 2026.

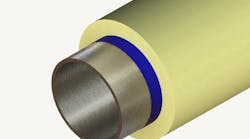

To ensure thermal and structural performance, AIS is supplying its ContraFlame MS200 insulation panel system for the platform’s underdecks. This is described as a lightweight, close cell, solid thermal insulation foam and GRP or epoxy laminate system that can provide A-rated fire protection while reducing the risk of corrosion under insulation.

The system, the company says, was selected partly because of the weight savings compared to a conventional belly pan solution (about 488 metric tons saved across the required 4,300 sq m of insulation). It is also said to operate within the project’s thermal insulation target of 0.25 W/sq m C, with a panel thickness of 120 mm.

Another stipulation was for the insulation system to withstand wave and wind slam pressures of up to 3 bar. AIS commissioned independent third-party finite element analysis studies, which it claims confirmed that ContraFlame MS200 can perform under extreme offshore conditions.

The BJ platform will have a design life of 25 years, hence the need for materials and equipment to operate continuously in harsh offshore and corrosive environments.