Intelligent completion control options extended

Over the past seven months, Baker Oil Tools has installed five intelligent well completion systems, bringing the total worldwide to eight. The company has found acceptance for InForce, the purely hydraulic system it developed as an alternative to early unreliable electro-hydraulic systems.

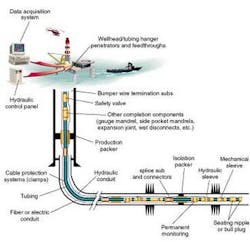

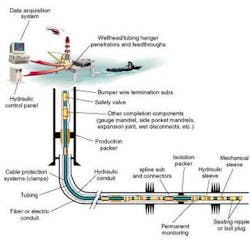

InForce was recently installed in three onshore wells in Oman, one in Indonesia, and two in Norway. The sliding sleeve is positioned either open or closed. The critical time for hydraulic systems is the installation process, when hydraulic hoses can be damaged. One of the company's recent installations suffered a hydraulic line leak. Meanwhile, a hydraulic downhole choke is now under development to expand the capability of the system, enabling regulation of the flow into the well from different zones.

Baker also developed the InCharge electric system. This offers an extensive degree of downhole control, for control of up to 12 valves from one tubing encased conductor ( TEC) line, which is also the communication line for pressure and temperature measurements.

Following a stack-up and functionality test at the beginning of the year, the first InCharge system was installed in a Petrobras onshore well in Brazil. The system will undergo six months' testing, after which, the completion is likely to be pulled and installed in a subsea well offshore.

For subsea uses, the electric system offers benefits over a hydraulic system with the number of lines to be handled, claims Jarle Haga, Intelligent Well Systems Manager. He said it offered easier integration with the direct control system. In contrast, where an operator can integrate multiple hydraulic lines into the completion, they are likely to go for a hydraulic system.

The industry has learned a great deal about the type of qualification testing needed, and this has contributed to improving the reliability of the systems, Haga says. The InCharge system has been through a qualification test program, and durability tests at elevated temperatures continue to run.

The major difference for intelligent well systems over conventional completions for downhole reliability is that the control lines for the lower valves are run across producing intervals in multiple zone completions. This represents a new kind of exposure for the control lines, difficult to simulate in qualification testing, Haga says.