Software tools aid long-term management, integrity of floating platforms

Marie-Francoise Renard, Bureau Veritas

Offshore floating units, usually deployed under long-term plan, handle field production. Consequently, they cannot easily be removed for dry-docking and repair. An asset integrity management system (AIMS) has been developed for major complex floating units.

The AIMS is a multidisciplinary coordination tool. It improves information and documentation transfer. More importantly, it helps minimize production shutdowns, and optimize maintenance and repair costs.

The AIMS program has been implemented to ensure management and continuous follow- up of all floating units from safety, environmental, operational, maintenance, and quality management viewpoints. It includes recommendations on inspection, maintenance, and repairs. The main activities within this program are the following:

VeriSTAR AIMS is an open, Web-based system with controlled access to allow AIM teamwork worldwide. The system is designed to improve inspection management and information control for different facility types. Information is stored and secured in a unique database, and can be accessed in real-time through the Internet or an intranet.

Integrity management cycle process

The integrity management cycle process comprises four main tasks:

- Development and maintenance of finite element modeling (FEM) and management tools

- Periodical re-assessment of the unit’s condition

- RBI analysis and IRM cycle

- Establishment and maintenance of emergency response.

Modeling software, data management tools, calculations services, and other analysis/trends are provided within the scope of the first assessment phase, which establishes the basis of the integrity management cycle process.

The IRM plan is refined based on engineering analyses, RBI analysis, operational constraints, and inspections results. The plan is developed and optimized regularly from the existing unit’s IRM plan. This system helps inspectors and others improve integrity control of structures, moorings, and offloading systems.

FEM models and management tools

The tools - which include software solutions for structural FEM analysis, hydrodynamic and mooring analyses, inspections, and data management - support each step in the unit’s integrity management cycle process, from IRM through the annual condition review.

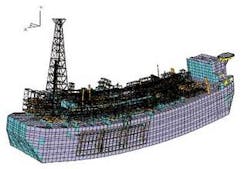

A global structural model is provided for each floating unit using finite element modeling, depending on the shape of the floating unit (ship shaped, barge, TLP, or spar) and on the building materials. All items of the hull contributing to the resistance or to the stress of the structure are modeled as illustrated.

Environmental data considered in the engineering analyses of FPSOs are based on the latest metocean information for each site, including waves, current, and wind characteristics.

Load cases corresponding to the actual operating conditions on board are considered in order to assess structure stress and fatigue induced by cargo, ballast, and other operating loads.

The fatigue life of selected hull details is calculated based on production loads, local design, and local weather. The procedure to establish fatigue life is based on the Miners summation approach, using stress-cycle curves.

Each floating unit also is provided with a mooring system database (mooring lines, dynamic positioning, offloading buoys, etc.). Hydrodynamic response of the floating unit also is assessed to give mooring and structural FEM analysis data.

For units coupled by flowlines, ropes, and gangways, a model is built containing the different floating components and their links.

Assessment of floating unit condition

The main aims in assessing the condition of the floating unit are:

- Analysis of inspection results and establishment of trends

- Comparison of monitored observations with finite element analysis

- Evaluation of possible modifications (operations, design) consequences

- Evaluation of structural degradation effects and consequences

- Evaluation of structure longevity

- Mooring/anchoring calculations.

Engineering analysis for hull and topsides structures, anchoring, and liaisons, provide information about asset integrity. Annual re-assessment is required to review the asset’s structural integrity, analyze the effects of modifications (environment, design, operations), trends (steel wastage, corrosion, crack propagation), and to validate the forecast of the structure’s condition (i.e., fatigue).

Inspection results are reviewed yearly, and recommendations on integrity are drafted. If relevant alterations such as thickness measurements, environmental data, monitoring data, and cracks observations have been implemented, models could be updated and the IRM plan optimized accordingly. Depending on inspection results, some re-analysis may be run using updated data to provide a re-assessment of the floating unit and to show its evolution compared to its known history.

Once results of inspections are available, depending on those findings (damages, crack observations, special study, design modifications, operations modifications, etc.), the following additional engineering analysis may be required:

- Structural reliability analysis

- Corrosion

- Fracture mechanics assessments

- Fatigue analysis (structure and mooring)

- Structural code checks.

Qualitative RBI analysis is carried out in order to optimize the IRM plan:

- Define and optimize inspection and maintenance intervals

- Develop and organize inspection plan

- Propose maintenance and repair strategy.

Re-analysis is completed before the annual review of assets conditions.

Emergency response service

Emergency response service is provided for assessment of damage stability and longitudinal strength of the floating units, year-round, 24 hrs/day. Damage can occur to both the floating units and the offloading buoy. The following damage types are considered in the ERS scope:

- Mooring line(s) failure

- Structural (and therefore stability) damage

- Mooring line(s) failure and structural damage.

Models can be applied to support decision making during emergency situations, and to help structural engineers and experts establish the best solution to protect/save the asset and the environment.

Documentation database

The database includes different types of data and accepts the most common Windows file formats. A typical list of data is provided below.

Drawings:

- Hull

- Mooring system

- Topsides structure.

Engineering analysis:

- (Re-)assessment results

- FEA calculations results

- RBI results.

Inspection management tool

The main objective of the inspection management tool is to support people in the AIM program along the Integrity Management Cycle process. The tool is based on a unit’s pre-defined system tree, which is customized and described based on the asset configuration, and the systems and equipment included in the AIM program. Each item concerning IRM activity is stored and linked to the respective system or item described in the asset system tree. The graphical interface is used to support and help the user quickly find the relevant information.

Classification and statutory status

This section of the software stores class data, namely:

- References of floating units (name, location, flag)

- Classification notations

- Certificates with expiration dates

- Class reports.

Structural FEM database

The structural FEM database provides the AIM team information on facility condition. The 3D viewer allows examination of the finite element analysis and results, rule checking, and data management.

The model is used for different calculations, using finite element calculations to verify yielding, buckling, and fatigue strength of structural components. Each facility has a dedicated database, developed during design or at any time in the unit’s life.

Typical contents of the Finite Element model database are:

- Global hull structure including FEA models and results

- Material properties

- Coating condition

- Corrosion condition

- Cathodic protection condition

- Thickness measurements

- Special specified details (turret, helideck, topsides, offloading platform)

- Relevant information on the hull and topsides assessment.

Finite element calculations and results can be examined. The user can verify the loads considered in the calculations and examine calculation results through manipulation of the ship’s 3D views.

The database begins in the as-built state, even if the facility enters the system during its service life. This represents the start of a facility’s history. All events entered into the database always will be compared to this initial state. After each survey, the hull condition is analyzed and stored in the database. Therefore, steel renewal and repairs are easy to forecast and optimize. Documented survey photos also can be stored in the database, for a pictorial history of the unit.

Mooring system database

The mooring system database has been developed using Ariane-3Dynamic, an integrated mooring and hydrodynamic analysis software for frequency/time domain simulation mooring analysis.

The database provides the AIM team in subsidiary and head offices with information concerning the “as-installed” configuration of the facility mooring system. The purpose of the database is to have an updated model ready to perform re-assessment of the mooring system, in particular for emergency response.

Typical mooring system database contents are:

- General data regarding the floating support, external bodies (shuttle tankers, loading buoys, and accommodation barges), bathymetry, and reference points required for performing any static and time domain analysis

- Mooring system data regarding geometry of the system and its composition (required for static and time domain analysis)

- Dynamic data: added Mass matrix, damping matrix, QTFs (used for the calculation of the second-order wave drift and mean wave drift loads) and RAOs (used for the calculation of the first-order wave motions) for calculation of the environmental loads on the system in the time domain

- Wave, wind, and current data to perform time domain simulation: type of wave spectrum, amplitude, period and heading; type of wind spectrum, velocity and heading; current speed and heading.