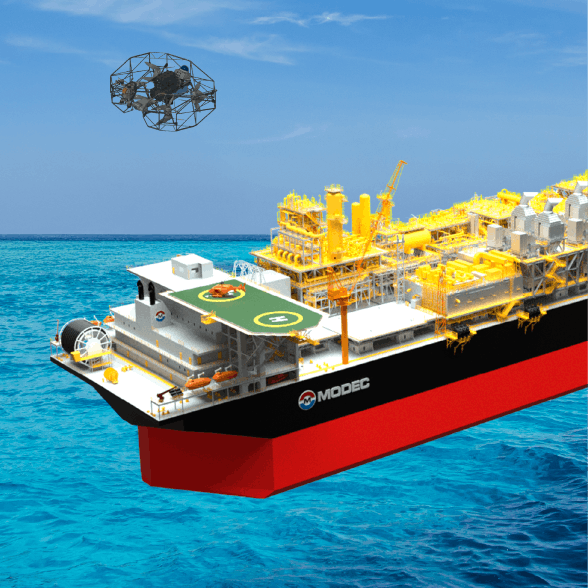

Drone partnership targets further improvements for FPSO inspections

MODEC has renewed a joint R&D agreement with Terra Drone Corp. This covers non-destructive internal inspections of crude oil storage tanks on FPSOs using Terra UT drones.

The two companies signed their initial joint R&D contract last year, and they now plan to widen the practical application and operational deployment of the technology.

MODEC points out that structural inspections on FPSOs must be conducted in parallel with production operations by a limited number of crew members. So being able to safely perform inspections without increasing personnel numbers onboard can be a major benefit.

FPSOs also require regular maintenance and inspections to ensure stable crude oil and gas production over 20 years or more of operation.

The venture’s drone-based solutions are designed to remove the need for manual inspections inside crude oil storage tanks on FPSOs, where the confined spaces present major occupational safety risks.

To date, the partnership has delivered reduced inspection times and enhanced safety, MODEC added, through adapting the Terra UT drone for inspection operations on FPSOs operating offshore Brazil.

Other achievements last year included:

- Improved measurement accuracy through upgraded ultrasonic sensors;

- Enhanced safety during inspection operations through equipping the drone with a gas detector;

- More efficient cleaning by the wire brush deployed by the drone, which MODEC said provides more effective removal of impurities and oil residues, such as wax, and enables up to 10 times more inspection operations in the same timeframe compared to the previous method; and

- Continuous power supply via a tethered cable that eliminates the need for battery replacement, which reduced the number of drone landings during inspections to one-tenth of the previous frequency.

The focus going forward will be on:

- Optimizing the airframe structure and design to improve robustness and operational stability for global deployment;

- Integration of high-resolution cameras for improved visual inspection capabilities;

- Redesigning the airframe to improved maintainability;

- Increasing the drone systems’ adaptability for work inside large tanks through reinforced and extended tether cables;

- Developing explosion-proof measures for the tethered cable system;

- Adapting the airframe design for air transport to enable global deployment; and

- Adding a gel-free measurement method for inspections, to support operational efficiency.