Focused formation fluid sampling method

Sample cleans up faster, provides real-time information

Chengli Dong, Chris Del Campo, Ricardo Vasques, Peter Hegeman, Noriyuki Matsumoto, Schlumberger

Anew formation fluid sampling method separates filtrate contamination from the virgin reservoir fluid, and the fluid sample cleans up faster than with the conventional approach. In addition to the new focused sampling method, downhole fluid characterization techniques, including composition measurement and single-phase assurance, provide real-time fluid property information to obtain representative samples in a short time and optimize the sampling process.

Formation fluid samples provide essential information for field development. Miscible drilling mud filtrate contamination reduces the sample quality drastically, and the current industry technique to obtain clean fluid samples requires a long pumping time. This can be costly, especially in deep offshore wells.

In the early stages of the industry’s exploration and development cycles, high-quality representative reservoir fluid samples provide essential information about the properties of the hydrocarbon fluids, such as gas/oil ratio (GOR), saturation pressure, density, and viscosity.

Wireline formation testing has proven to be a reliable way to obtain these representative reservoir fluid samples at less cost than alternative methods.

While drilling, contamination from miscible drilling mud filtrate, as occurs when oil sampling in oil-base mud (OBM) wells, remains the biggest risk in obtaining good reservoir fluid samples. The sample quality is reduced drastically by mud filtrate contamination and makes pressure-volume-temperature (PVT) laboratory analysis unreliable and often incorrect.

To achieve a clean fluid sample with the current openhole sampling techniques, long pumping times may be needed, which can be costly and risky in offshore wells. Additionally, if the mudcake is poor, mud filtrate may continuously invade the formation during sampling, negating the effect of pumping and limiting any further decrease in contamination levels.

The focused sampling method can separate drilling mud filtrate contamination from the formation fluid in the early stage of the sampling process, acquiring a clean reservoir fluid sample faster than with conventional sampling techniques. A field test of this new technique showed that the fluid sample cleaned up more rapidly on flow and that reservoir samples of higher quality were obtained in less pumping time.

Additionally, the techniques for downhole fluid characterization include downhole composition measurement, fluid type identification, and single-phase assurance. The real-time composition and fluid type techniques use the absorption properties of hydrocarbons in near-infrared (NIR) spectroscopy, and reservoir fluid composition is quantitatively determined. Measurement of real-time fluorescence is used to assure a single-phase fluid sample, especially for condensate gas.

Focused sampling

The new technique, called “focused sampling,” in early field tests has shown excellent results. During a conventional formation fluid sampling operation with a probe, the downhole formation testing tool makes a packer seal on the borehole wall that connects the sampling tool to the formation and isolates the internal flowline in the tool from the borehole. In a typical overbalanced drilling situation, the mud filtrate will contaminated the formation near the borehole wall.

The first fluid entering the flowline is fully contaminated with filtrate. To decrease the amount of contamination in the incoming fluid, the company’s tool pumps fluid from the formation. After a period of time, the virgin fluid begins breaking through the borehole wall in the center of the isolated sampling zone, while contaminated fluid continues to flow in through the periphery.

According to theory and in practice, during the pump-out operation the level of contamination in the incoming fluid decreases as an increasing amount of virgin fluid breaks through the borehole wall. The rate of contamination decrease slows during the pump-out operation, and the level of contamination in the incoming fluid will not reach zero in any practical length of time. The inability to reach zero contamination is caused by filtrate continually feeding the sampling zone from extended portions of the formation, and is caused in some cases by reinvasion of the sampling zone through the surrounding mudcake.

To achieve very low contamination levels in the incoming fluid, the downhole tool must engage in pump-out operations for an extended period of time, which can be expensive and risky in an openhole environment.

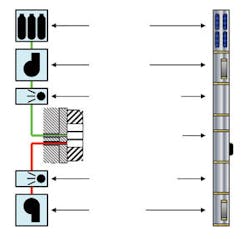

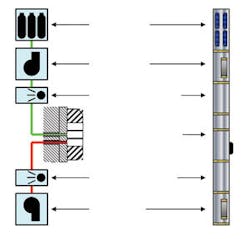

The focused sampling operation differs from a conventional sampling operation in equipment, technique, and results. In addition to the packer seal used to isolate a sampling zone of the formation from the borehole, a secondary intake is used to separate the central area of the sampling zone from the perimeter area. The central and perimeter areas are each connected to a separate flowline in the downhole tool, referred to as the sample and guard flowlines, respectively.

When virgin fluid breaks through the central area of the sampling zone during the pump-out operation, it enters the sample flowline first. Over time, the fraction of the sampling zone producing virgin fluid grows until it completely engulfs the central area. The contamination level of the fluid entering the sample flowline decreases much more rapidly than the contamination level of the fluid entering the single flowline of a conventional sampling tool.

In addition, it is possible to achieve zero contamination in the sample flowline, because at some point, all contamination in the periphery of the sampling zone will be drawn into the guard flowline only, leaving the sample flowline protected from contamination.

Downhole apparatus

To validate the new sampling technique, several field tests were conducted in the downhole environment with a focused sampling toolstring. An optical fluid analyzer is placed on both sample and guard flowlines to obtain real-time data during downhole sampling operation for comparison of fluid quality between the two flowlines. The typical configuration requires a pump on both the sample and guard flowlines.

One or more sample containers are placed on the sample flowline to retrieve fluid samples for subsequent laboratory analysis and comparison to fluid analyzer data at the time of retrieval. In all the field tests, a conventional probe module was also run with the toolstring for performance comparison to the focused sampling probe. Each of the field tests used the wireline tool modules with a slightly different toolstring composition such as multiple sample modules, redundant hydraulic power modules, etc.

When sampling in a vertical well, the clean reservoir fluid flows mainly horizontally into the flowline of the formation test tool, whereas the mud filtrate primarily flows vertically before entering the tool. Therefore, a vertical well with horizontal permeability much larger than vertical permeability would favor the flow of the reservoir fluid, resulting in quick cleanup.

However, in the first case the operator drilled a highly deviated well with oil based mud (OBM) in a formation with small permeability anisotropy, implying a small difference between vertical permeability and horizontal permeability. Therefore, with the well deviation and low permeability anisotropy, expected sample cleanup time would be lengthy. To make the situation even worse, the reservoir fluid in this case was a heavy oil with a much higher viscosity than the mud filtrate.

The resulting mobility contrast implied a relatively easier flow for the OBM filtrate than the reservoir fluid. Conventional experience indicated that all these conditions together made this case one of the most difficult situations in which to collect representative reservoir fluid samples with low contamination levels.

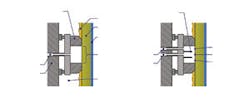

The field case example indicated that most of the filtrate was flowing through the guard flowline resulting in a much more rapid cleanup of the sample flowline fluid. After the company compared the results from the conventional probe, the focused sampling technique worked effectively in this difficult sampling situation. Also, this sampling technique collected high-quality samples with much lower contamination levels. Furthermore, the contamination level was reduced very slowly with the conventional sampling probe, as indicated by the high sample contamination level (40%) even after pumping out for more than 8 hrs. This implied that the conventional sampling probe was unlikely to obtain samples of less than 5 % contamination level even with extremely long pumping times.

Sample quality was substantially impro- ved with the focused sampling technique, with a contamination level less than 4%, and this improved quality was achieved in a significantly reduced pumping time.

Downhole fluid composition

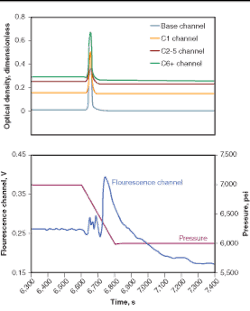

The downhole fluid characterization techniques include downhole fluid composition measurement, fluid type identification, and sample single-phase assurance. The real-time composition and fluid type techniques use the absorption properties of hydrocarbons in NIR spectroscopy. The fluorescence technique is used for single-phase assurance while sampling, especially for condensate gas.

This analysis provides the ability to identify the reservoir fluids at different zones before sampling. A field example of the downhole composition analysis determined where compositions of the fluids from four different zones were with the fluid analyzer tool before sampling. The tests found a large fluid composition variation, and sampling points and number of samples were much better determined with the information of the fluid composition at different zones. High-quality representative samples were taken, and the sampling process was optimized with the aid of the downhole fluid composition analysis.

Single-phase assurance

It is important to keep the fluid in single phase during the sampling process. If phase separation occurs, the samples collected may differ from the reservoir fluid because one of the separated phases may be left in the formation or flowline of the sampling tool. Monitoring phase separation for condensate gas is difficult because only a small amount of condensed liquid drops out when the pressure is slightly below the dewpoint. Real-time fluorescence measurement is used to monitor phase separation during sampling to assure single-phase sampling.

Fluorescence is caused primarily by aromatic components, such as resins and asphaltenes. After aromatic molecules are excited with an incident light at a certain wavelength (usually ultraviolet or visible), the absorbed photon energy can be released in the form of light but at a longer wavelength, causing the fluorescence effect. Depending on its aromatics content, a typical oil has a higher fluorescence signal than gas, while water has no fluorescence.•