Statoil making global collaboration a (virtual) reality

High-speed links increase team effectiveness

Doug Wille

Landmark Graphics Corporation

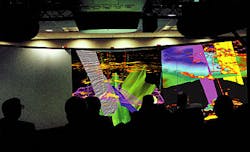

Statoil and Landmark use the immersive environment to demonstrate transcontinental team collaboration between Houston and Stavanger.

- Transcontinental collaboration is demonstrated with John Gibson, Vice President, Landmark's Integrated Products Group in Houston, and Adolpho Henriquez, Statoil's Director of Subsurface Integration, in Norway. Using video conferencing and an ISDN connection, the two teams view a presentation and seismic data simultaneously. [16,879 bytes]

- Bringing together asset teams of geoscientists, drilling engineers, service company representatives, and managers in a room-size visualization facility helps to achieve faster, more accurate decisions with reduced risk. [26,771 bytes]

One way innovative energy companies are beginning to tear down outdated organizational and functional barriers is by combining integrated exploration and production (E&P) software with high performance 3D graphics hardware in new, collaborative working environments.

For the first time, members of a cross-functional team can share a common virtual reality (VR) experience across continents - in real time. As a result, they can reduce decision-making cycle time, and achieve more accurate investment decisions.

Immersive environments

The benefits of storing diverse E&P data types in a common repository have long been recognized in the petroleum industry. Effective data level integration allows an individual to quickly analyze a myriad of data and make decisions. However, sharing information or analysis with a colleague, especially in another discipline, generally requires a trip down the hall, a phone conversation or an exchange of email messages.Until recently, the most effective way for multidisciplinary team members to work collaboratively with one another and a shared data set was to huddle around one of their computers. Otherwise, they lacked a common visual environment that would enable them to take full advantage of data level integration.

The advent of relatively inexpensive, large-scale 3D visualization and virtual reality technology is rapidly changing all of this. Available options include large-scale immersive display environments (such as curved screens 10 meters wide by 4 meters tall), voice-controlled software, and VR devices that actually allow users to feel the data. This broad range of technology offers multidisciplinary teams in companies of all sizes remarkable new ways to view, interact with, and analyze data in a common 3D environment.

By immersing geologists, geophysicists, reservoir engineers, production engineers, drilling engineers, managers, partners, and suppliers in a common 3D visual experience, they can literally see one another's' perspectives. Each E&P specialist can display information and analyses using familiar desktop software. Merging information from multiple disciplines by way of common 3D visualization software facilitates easier analysis of spatial relationships, especially in areas with complex geology and wellbore paths. Therefore, diverse operational and technical professionals can identify problems more quickly and design more comprehensive, better-integrated solutions.

Remote collaboration

Leveraging common project and company-wide data repositories, Statoil, the Norwegian state oil company, is already reaping the benefits of data level integration. A wide range of oil and gas life cycle information is accessible. By combining data integration with a tightly integrated suite of software applications, individuals can fully analyze all information relevant to the problem at hand.However, to meet aggressive global business goals, the company also needed to knock down barriers between various domain experts - a long list of people who bring their specialized knowledge to even the simplest investment decision. What was needed was an effective way for members of a team to integrate diverse E&P information as part of a shared work process.

As Statoil's CEO, Harald Norvik, said recently, "To find and produce more oil and gas, we have to tear down the fences between professionals. As a learning organization in a global environment, our ability to collaborate across organizational, geographical and professional boundaries is crucial to our success."

The solution to the need for a collaborative work process is Statoil's Advanced Visualization Center (AVC), which opened in Stavanger in late 1998. A combination of virtual reality display technology, high end computing systems, and the latest in integrated software, the AVC is the place to leverage the benefits of data integration and achieve a whole new level of cross-functional work process integration.

The center was designed as a practical working environment for asset teams. All the same advanced software applications available on users' desktops can be run and displayed within the center. The center is connected via high-bandwidth network to Statoil's stores of information. The center's large projection screen is designed so that teams with 15-20 members can view the same information, in true stereoscopic 3D if desired. Decisions in such diverse workflows as platform planning and prospect evaluation are being made in real time, with all of the data and experts on hand through the use of this center.

Not only does the AVC display many different applications on the same large screen, it also visually integrates diverse data types in a common 3D view, using Landmark's OpenVision software. Seismic data and interpretation, well logs and geologic cross sections, and reservoir models can all be merged in a single 3D display. Relationships among faulting, reservoir performance, and seismic character can be seen. Subsurface features and reservoir parameters can be altered at will to test multiple working hypotheses. The 3D view can be rotated, panned and zoomed to explore spatial relationships from many different angles. As a result, well planning time is reduced, and cost savings are achieved by allowing teams to leverage available information and expertise within a shared environment.

Improving collaboration among team members located in a single facility is providing significant business benefits to Statoil. But the company's long-term vision is much larger. "Statoil's goal for 2005 is to produce 1 million b/d of oil, with half of that will come from countries outside of Norway," said CEO Harald Norvik at the opening of the AVC in November. "Our people must be able to work on the same models, at the same time, regardless of where they are located in the world - Baku, Caracas, Houston, or Stavanger."

International collaboration

To extend the collaborative concept around the globe, Statoil partnered with Landmark, Silicon Graphics, and Telenor. During the opening of the AVC, teams in Houston and Stavanger were able to demonstrate intercontinental collaboration while planning a wellbore in real time. Both teams were working in an immersive 3D-visualization environment. The collaborative connection was made with low cost ISDN communications technology. The teams shared a common 3D view of all data necessary to plan the well, including seismic, well paths, log curves, and a simulation model. Both teams instantly experienced changes in the orientation of the view or the information displayed, despite being separated by thousands of miles. Video and audio conferencing enabled interactive communication throughout the entire process.Statoil intends to leverage both local and remote collaboration concepts to achieve more advanced operational integration. As Norvik noted, "We envision a near future in which drilling engineers on platforms and rigs operating offshore and engineers and geologists in our offices can quickly take decisions leading to more productive and cheaper wells." By collaboratively connecting its offices with drilling, production, or seismic acquisition activities in the field, Statoil's global organization will be able to make real-time operational decisions more effectively than ever before.

Conclusion

As the petroleum industry enters the new millennium, team-based collaborative work processes, fueled by the fusion of integrated software, VR technology, high performance computing, and high bandwidth communications will produce a fundamental business transformation similar to what the industry experienced with 3D seismic technology.Over the next decade, collaborative VR environments could have as great an impact on corporate productivity as the interactive workstation has had on individual productivity over the past decade. Energy companies that adopt this new technology should find themselves better able to compete in the volatile energy marketplace of the future.

Author

Doug Wille is the Director of Product Management for Landmark Graphics' suite of Integrated Interpretation Solutions. He holds a BS in Geology from Wright State University and an MS in Geophysics from Cornell University. He is a member of SEG and EAGE.

Copyright 1999 Oil & Gas Journal. All Rights Reserved.