Finland: Compact propulsion system passes trials on Pemex-chartered vessel

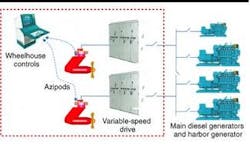

Ship propulsion systems typically com-prise a prime mover; diesel engine, gas turbine; power transmission equipment, shaftline with gearbox; steering and control, and the propeller. Some vessel owners, however, prefer electric to diesel-mechanical propulsion. In this case, power is transmitted from the prime mover to the propeller electrically, with neither gearboxes nor long shaftlines being needed.

One of the benefits of the electrical approach for vessel owners is that prime movers can be run constantly at the optimal rotation speed. This saves fuel and makes the propulsion system easier to control. In addition, noise and vibration are reduced, and since there are no gearboxes or long shaftlines, maintenance needs are lessened. At the same time, good maneuverability is demanded, and the system's various components should not take up too much room.

The shipyard has other priorities. Ideally, the propulsion system should allow flexible positioning of the diesel engines or other prime movers inside the ship's hull. A constraint for the propulsion system supplier, however, is the delivery time. Often this is as little as three to four months for vessels in the lower power range.

ABB has developed a podded electric propulsion system, the Compact Azipod, which is small, modular, offers improved performance and steering capability, and can be delivered to the yard in a few months. Power and thrust come from a permanent magnet motor driven by ABB's proven, water-cooled ACS 600W converter. Another feature is use of direct torque control, which allows accurate control of motor speed and torque, without pulse encoder feedback from the motor shaft.

Compact Azipods have been designed for a power range of 400kW to 5MW, and are suitable for a variety of offshore vessels. The power transmission and steering module can be installed in the ship's hull during a convenient time in the ship construction program. Pre-assembled strut and motor modules can be delivered, installed and connected to the power/steering module at any time until the vessel's launch. The relatively small number of components in the Compact Azipod also reduces the operator's spare parts inventory, making servicing easier. The system is also dismountable underwater.

The first two units were installed last year on a new multi-function platform support/ROV vessel, the Normand Rover, built by Soviknes Verft for Island Offshore in Ulsteinvik. The hull was built at Aker Tulcea in Romania, with the completed vessel delivered last November. Its first charter is from Pemex, to perform subsea services in the Gulf of Mexico.

The vessel is a refinement of Rolls-Royce's UT 745E design, with an overall length of 92.4 meters. It features a Class 2 dynamic positioning system in addition to diesel-electric propulsion, based on two 2.3MW Compact Azipods. It is equipped with a moonpool, helipad and a 100-tonne offshore crane, and can house a crew of up to 146. In the interests of safety and the environment, low noise machinery and bow thrusters have been selected.

Soviknes Verft had a tight schedule from the arrival of the hull in Norway in June to completion in mid-November. The pods were delivered ready-to-mount by ABB, with 14 days being allocated for their mounting. In the event, installation was effected within seven days. During subsequent sea trials, the Compact Azipods fulfilled all technical and maneuvering requirements. ABB's DP system, with functions including Follow ROV and Way-point tracking, also performed well, helping to shorten the total sea trial time.

Since this contract was completed, ABB has won a $42 million order from Santa Fe Inter-national to supply electric propulsion systems and power plants for two new deepwater semisubmersible drilling rigs. These are being built by PPL Shipyard PTE in Singapore, to a Friede & Goldman ExD design, with the first rig scheduled to be delivered by late 2003.