Raw water injection first for Columba E expansion scheme

The world’s first subsea raw seawater injection system will enter service soon in the UK northern North Sea. CNR International opted for a seabed pumping station as the waterflood solution for its Columba E field. The alternative, injecting water via a dedicated pipeline from a platform, would have cost more while delivering less in terms of pressure boost.

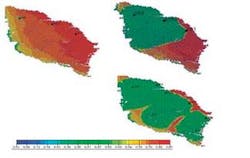

Columba E, extending across UK blocks 3/7a, 3/7b, and 3/8a in 145 m (476 ft) water depth is the largest and most southerly of five faulted structures known as the Columba Terraces, with 270 MMbbl of oil originally in place. All lie south and west of Ninian, the giant oilfield developed originally by Chevron with one concrete-based and two steel production platforms.

CNR International (UK) and its predecessor Ranger Oil (UK) have operated the Terraces since their discovery in the 1970s. Development, however, had to be put on hold until the 1990s, when Ninian’s production decline eased infrastructure constraints. Even then, says CNR International’s VP for Exploitation and Business Development, James Edens, they had a tough time securing platform drilling slots due to Ninian’s ongoing infill drilling and workover/intervention programs.

The current project represents Columba E’s fourth development phase in the past 10 years and is designed to sustain production from the field well into the next decade.

Reservoir targets

“When Ranger first appraised the field with a view to development in 1995,” Edens explains, “the idea was to drill two extended reach producers from Ninian Southern out to the platform’s offset limit. One well was designed to intersect the good quality Upper Brent rock containing 20% of the field’s oil, while the other would be dedicated to the poorer quality Lower Brent rock, which had 80% of the oil in place.”

Columba E came onstream in 1998 at 11,000 b/d, via the EP1 producer. “This was a fantastic initial rate,” Edens says, “and that well produced 6 MMbbl cumulative up to 2001. EP2 followed at the end of 1998 at a rate of 1,500 b/d and has produced 2.4 MMbbl to date. These two wells demonstrated that viable production was possible from Columba E, but also that the field would take a long time to give up its prize due to the poor rock quality.”

Ranger considered renting further slots on Ninian Southern to drill three to four more wells, including injectors for pressure maintenance and waterflood, using the platform’s water injection facilities. “But this would have been a relatively high cost option,” Edens explains, “as a review showed that getting the injectors out with a far enough offset to Columba E would be beyond the reach of the platform’s drilling capability.

“We felt that with limited upgrading of the platform’s drilling rig, we could get out to the better part of the Upper Brent section with a 6,706-m (22,000-ft) offset, but only in the far western extent of the field. Ultimately, the Columba E field group did sanction the upgrade program when the UK government agreed to grant royalty relief for the Columba E Terrace.

In April 2002, CNR drilled the EW3 water injector into the E Terrace. Even with the upgrade, Edens says, “we were still operating at the limits of the platform’s offset capability. The well had as gun-barrel straight a trajectory as was possible, but we suffered formation collapse twice while tripping out after reaching the reservoir.”

“In the event, we were third time lucky, but this exercise took up a tremendous amount of cost and time. Also, being fully occupied with drilling EW3, we were unable to pursue at the time other planned developments in the southern region of Ninian and the Columba B area, which were deferred almost a year as a result.

“On the plus side, EW3 did show that waterflood was feasible on Columba E, and we also saw significantly improved performance as a result from EP1. This gave us sufficient confidence to proceed to waterflood at a full-field scale.”

Having proved this waterflood capability, Edens adds, “We wanted to do it again, but in a more cost-effective way, via subsea injectors and platform producers. The two injector wells would be drilled out to a further offset than the platform’s drilling radius would allow, maximizing the waterflood development extent. Our next issue was how best to get the injection water into the reservoir.”

Water transfer

According to Edens, “Our entrepreneurial guys in Aberdeen had been looking at subsea raw seawater delivery for some time.”

McDermott in London was the original pioneer in this regard, leading a joint industry project in the late 1990s. Out of this JIP, a scheme was devised for Columba E. “The technology is basically simple, and based on proven subsea pumping, but used in a novel way,” Edens says.

CNR discounted the alternative of a dedicated injection pipeline from Ninian Southern mainly on technical and cost grounds. In late 2003, the plan was to put in two new platform-drilled producers in the northern part of Columba E, followed by two to three subsea water injectors, directly to the south of the producers, to be drilled by a semisubmersible. The subsea raw water injection facilities would be installed on the seabed in close proximity to the wellheads, eliminating the need for a new water injection pipeline from Ninian Southern.

The raw seawater systems, as the project’s 2003 environmental statement explains, could deliver higher pressures into the reservoir than would be possible with the existing injection facilities from Ninian Southern. This higher delivery pressure, in turn, was expected to translate into higher hydrocarbon volumes from the new production wells. The preferred option would also involve less change to the existing infrastructure around Columba E and Ninian Southern, which had economical and environmental benefits.

Britain’s Department of Trade and Industry approved the development in March 2004, but at that point CNR was focused on the acquisition and transfer of operatorship from Eni of the Tiffany and Balmoral fields in the central UK North Sea. “We decided to defer our investment in Columba E for a year,” Edens says, “while also using that time to make sure that this was the right way to go. Ultimately, we concluded that the economics were robust and proceeded with project delivery.”

During the summer of 2004, the company drilled one of the two extended reach Phase 4 producers (EP4). The well came onstream that August at 7,000 b/d, clearly demonstrating a strong waterflood response. Production continues today at more than 2,500 b/d cumulative from the three platform producers balanced by the single injector.

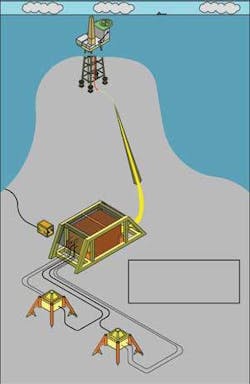

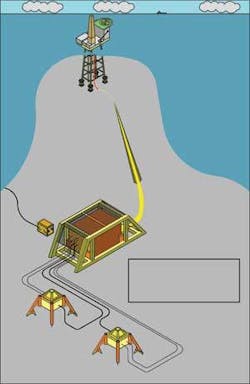

Framo Engineering designed and built the electrically powered subsea seawater injection pumping station. The system will provide injection capacity of 55,000 b/d and a normalized injection pressure of 32 MPa (320 bar), although this could be raised to 39 MPa (390 bar) if reservoir fracing operations are required.

Two subsea injectors will be drilled from nearby seabed locations and deviated to the targets in the reservoir through directional drilling. The subsea injection facility will then be connected to the wellhead via flexible jumpers.

The pumping station’s seawater filter inlet is built into the openings on the side of the filter top section. The openings are located 4.5-5 m (14 3/4-16 1/2 ft) above the mud line to minimize ingress of particles into the filter. The filter will be kept clean through regular water purging.

Ninian Southern will supply power for the pumping station via a 7.4-km (4.6-mi) umbilical designed and manufactured by Oceaneering Multiflex and installed on the seabed last summer. The pumping station rests on a suction base with four mud mats, one at each corner of the structure.

Drilling of the first two injector wells started late last year, and both should be completed simultaneously this spring, with injection rates of 10,000 b/d each. All subsea equipment was installed by the end of 2006, and shortly the pump system will be deployed within the pump station, and the subsea hookups will be completed.

“The injectors will be chemically dosed with a biocide three times a week,” says Edens, “with a second scale inhibitor also added during the first million barrels. We will also have the ability to frac the formation at startup if we choose.

“Once the system has been re-pressurized, the producers should flow naturally at 5-7,000 b/d gross fluids each.” He also points out that artificial lift was installed in two of the platform producers when the injection project was deferred in 2004.

Like the existing well stream from Columba E, Phase 4 oil and associated gas is separated and treated on Ninian Southern, with the crude exported to the Sullom Voe terminal in Shetland via the Ninian Pipeline System. The main modifications to the platform associated with this scheme include installation of a new switch room to accommodate controls for the subsea water injection facilities; a step-up transformer to control power feeding through the high voltage umbilical; and a variable-speed drive to regulate flow through the pumping station.

To date, Columba E has produced nearly 11 MMbbl of oil. CNR hopes that the new waterflood scheme will extract another 30 MMbbl from the four producer locations, connected to at least an estimated 80 MMbbl in place. “That still leaves two-thirds of the reservoir - around 190 MMbbl - not connected to these three producers. We keep challenging our guys to find new methods of accessing those reserves,” Edens says.

Later in the field’s life, the raw water injection system could be re-deployed or replicated to access those targets or used to replace an existing water injector well on the Lyell field to the west of Ninian, Edens says. “We could also transfer it to Columba B and D, taking out existing injectors and converting them back to producers by putting in raw water injection.”

Jeremy Beckman, Editor, Europe