OTC 2025: New approach mitigates ESP risks in critical offshore applications

By Tyler Shirk, Baker Hughes

In risky applications like deepwater and high-investment wells, premature ESP failures and lost production are costs that operators cannot afford. This is especially true in critical applications where intervention costs are high and lead times are long. In these situations, reliability and uptime are nonnegotiable.

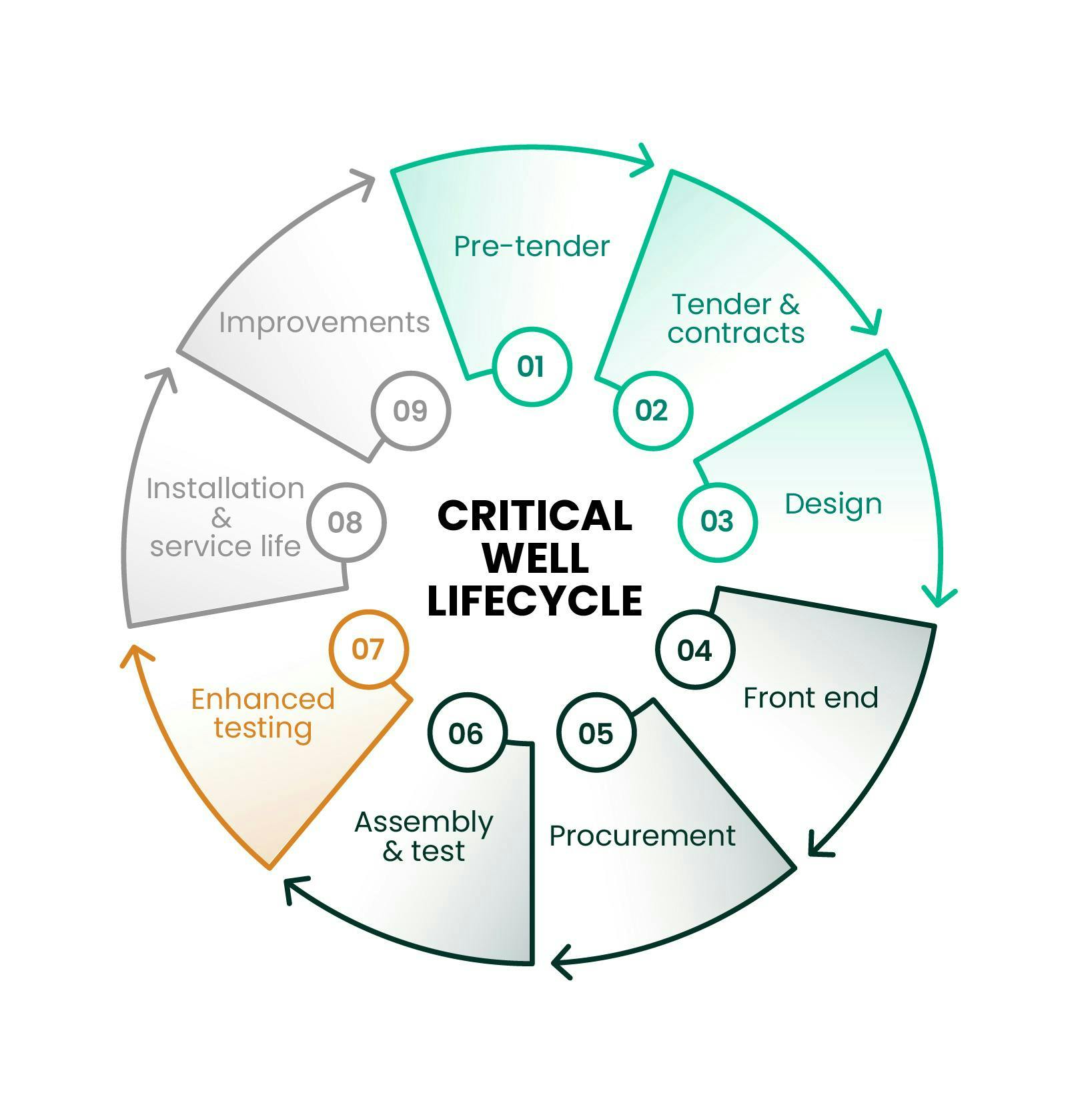

Rethinking ESP system construction, testing and deployment is improving reliable, long-term ESP performance in the most challenging applications worldwide. By significantly mitigating risk through a systematic well life-cycle approach that elevates quality control and project management, it is possible to extend ESP performance to reach new levels of consistency and reliability.

Challenges

In installations where ESPs are boosting production from complex fields, reliable performance is critical because downtime is extremely costly. From completions and topsides issues to flow and power requirements, many things can go wrong to compromise performance. That is why designing a complete system is important. But consistently delivering complete systems isn’t a simple matter of connecting pumps, motors and seals. It’s connecting the most reliable technology from the topsides to the bottom of the ESP to work together in the most efficient and effective way.

Manufacturing quality and reliability is also on the list of challenges. Approximately 5% of ESPs are installed in critical deepwater/subsea wells, which commonly require the ESP to lift up to 40,000 bbl/d. For these critical wells, standard manufacturing processes are inadequate because small manufacturing defects—material defects or dimensional nonconformances—can have costly consequences.

This third challenge is that orders for high-spec ESPs and associated components can take nine to 12 months on average. When this process focuses on securing individual parts instead of managing the orders as part of a system, it is less likely to result in the best technology being assembled in the most effective way and limits continuous improvement throughout the life cycle of the well.

Rethinking the process

Looking at an artificial lift solution as a system makes it possible to preempt incidents by improving the individual components of the ESP system and focusing on how they work together in the field. Each system is also designed and tested for specific well conditions, an approach that aligns with the way operators conceptualize artificial lift systems. To mitigate the risk of downhole failures, operators design each system holistically for certain conditions based on past issues and performance.

PRIMERA, launched in January 2023, is a process-driven artificial lift service that mitigates risk and maximizes well economics throughout the entire production life cycle. This systems-lifecycle approach helps optimize lift performance and field reliability through engineering and application reviews, criticality assessments, checkpoint reviews and final engineering system design reviews. Following this approach, ESP system development is managed as a project with a single point of contact and support from a dedicated team of engineers, assemblers and quality control experts.

The process begins with meticulous attention to the chemical and mechanical properties of the system parts, including materials selection and a process for managing raw material traceability. By selecting reliable technology and then testing each component as part of a larger fit-for-purpose system, it is possible to understand the interplay of the parts and identify slight nonconformities that could impact performance. This “dress rehearsal” takes place in a low-consequence environment where system shortcomings can be addressed before deployment.

Testing

The Baker Hughes Artificial Lift Research and Technology Center (ALRTC), located in Claremore, Oklahoma, was designed with a full range of engineering and testing services to ensure high-spec system validation. The facility is 82,000+ sq ft and fitted with six vertical test wells that permit testing beyond industry standards.

Because artificial lift systems have thousands of parts moving together at speeds as high as 3,600 rpm and are deployed in complex environments, there are a lot of factors that impact equipment longevity. If one dimension is out of spec by a miniscule amount, it can cause a failure. Because of the heightened level of performance required for critical wells, inspectors record hundreds of measurements as proof of dimensional conformance of all critical parts, and testing verifies their integrated functionality.

Each system is tested to the parameters for which it was designed, with experts looking for ways to improve system performance for greater reliability and uptime. Once the components are assembled, the entire system is deployed in a test well with characteristics that mimic a specific well’s downhole conditions to create a test environment that offers the clearest picture possible of how it will perform in situ.

As part of the testing process, fluid is introduced, and endurance testing proves robustness with the system running for 24 to 72 hours at specific operating levels to ensure a good representation of performance requirements.

Motor tests validate variable speed drive compatibility, with follow-ups verifying motor dialectic properties. Vibration monitoring is another important part of the process so, prior to testing, impellers and rotors are mapped to fine tune vibration, with testing performed to tight vibration tolerances. Pressures and temperatures are also monitored at various points along the ESP as are flow rates and horsepower. Anticipating and validating these parameters can improve mean-time-to-failure rates.

While the success rate for these systems is high, it is not 100% so pre-test and post-test inspections are carried out for each system to identify changes during testing, understand why the change occurred and address performance issues prior to installation.

Case study

This systems approach was used to address challenges for an operator offshore Brazil on a heavy oil field. Aggressive fluid conditions required constant chemical injection of H2S scavengers, scale inhibitors and emulsion breakers in six critical wells. Despite efforts to improve output, the operator experienced subpar reservoir productivity, with the ESP system operating outside the recommended range. Performance of these wells was crucial to the economics of the entire field.

The PRIMERA service established precision manufacturing and inspection processes to deliver a reliable ESP system. This included ensuring 100% dimensional inspection of critical parts, material identification to verify required special metallurgy, impeller and rotor mapping to guarantee low system vibration, and stringent systems testing at the ALRTC.

The results exceeded all the operator’s objectives with zero premature failures in more than 14 years, resulting in an 8.9 years mean-time-to-failure rate, which is 2X greater than the typical ESP runlife in similar adjacent fields.

Baker Hughes is exhibiting at booth 2227 at the Offshore Technology Conference (OTC) May 5-8 in Houston, Texas. The company's executives are taking part in a number of OTC technical sessions and panels, including but not limited to:

-

Allyson Anderson Book, the company's chief sustainability officer, is presenting the "Accelerating Energy Expansion: A Business Case for Sustainability" executive dialogue session on Monday, May 5;

-

Ajit Menon, VP of Geothermal and Energy Transition, is one of the speakers during the "The Geothermal Revolution" panel on Monday, May 5; and

-

Tayo Akinokun, SVP of Oilfield Services and Equipment, is one of the speakers during the "Energy Development in Argentina and India – Business Opportunities in Dynamic Energy Markets" panel on Tuesday, May 6.

About the Author

Tyler Shirk

Tyler Shirk is the PRIMERA premium artificial lift services business leader for Baker Hughes based in Claremore, Oklahoma. He is leading a business comprised of systems engineers, project managers and technicians focused on designing and manufacturing high-spec artificial lift systems for high-risk applications.

He has held positions in engineering, product management and service delivery. He has 12 years of experience with Baker Hughes, primarily in Completions & Well Intervention and Artificial Lift Services.

Shirk graduated from Oklahoma State University in 2012 with bachelor's degrees in mechanical engineering and aerospace engineering.