Unmanned aerial vehicles (UAVs) are providing a close-up view of an increasing number of offshore structures. One specialist UAV operator, Horizon Data Services (HDS) has also started a co-operation with Bureau Veritas on Class inspection.

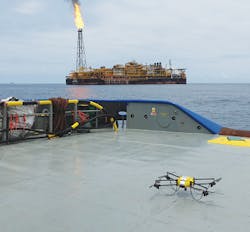

Drone operating offshore Angola. (Images courtesy Horizon Data Services)

HDS, formed in 2014, operates UAVs and crawlers for inspection of a wide range of facilities in the oil and gas, marine and nuclear sectors which are hard for human technicians to access (confined spaces, work at height and radiation). Its team includes seasoned drone and crawler pilots, and the company also provides pilot training for client personnel. In the oil and gas sector, it works mainly in the Middle East and offshore West Africa, and is qualified by companies including BP, Chevron, Total and Oceaneering.

“We are operators – we don’t build our own drones,” said HDS’ Operation Director Maxence Boyenval. “But we adapt existing sensors to existing drones for new purposes, for instance gas/radiation sensors for inspections in hazardous areas.” For external offshore inspections, the company uses UAVs to perform Global Visual Inspection (GVI) and Close Visual Inspection (CVI) of flare stacks, topside modules, underdecks or hulls. The drones for internal inspections, which move around within cages designed to protect their rotor blades, are for use in confined or hazardous internal spaces such as cargo or ballast tanks for Class Inspection programs, performing tasks such as visual inspections or checking welds by taking ultrasonic measurements. “For each application the drone is fitted with a different camera,” Boyenval explained. “Flare stack inspections might require increased zoom capability, while for internal campaigns, lighting is the main issue.”

Following a survey, HDS delivers an inspection report and package containing all photos and videos taken. Based on the pictures or on lidar data, the team can also develop a 3D model of the structure surveyed for export to other software or to be managed in the company’s Horizon 360 data management platform. “This allows clients to download all their documents and photos and interact with us, although typically, those in the oil and gas sector only want to download data as they don’t have the time or resources to do more,” Boyenval said. “We can, for instance, provide 3D models of their flare stacks, but what they mainly want is to compare the current condition of the structures inspected with pictures taken, say, two years ago, to see whether an anomaly has worsened.”

Crawler undertaking internal inspection.

HDS claims to be on of the first UAV operator to be Class-certified by Bureau Veritas, and the two companies have been discussing ways of performing Class inspections of facilities at sea that comply with IACS (International Association of Classification Societies) rules. HDS also has a partnership with Oceaneering under which it supports the latter’s maintenance and inspection teams on offshore assets in Europe (excluding UK) and Africa.

“In some countries in West Africa, it is important to have a partner that is already working in-country,” Boyenval said, “because of the civil and military regulations that affect importing of drones and the need for authorization to operate them. In Nigeria Nigerdock, which works for all the offshore operators, is another partner, proposing our service to its clients. Once we have secured more jobs in the region, we may set up local offices to support our activity both in West Africa and the Middle East….

“We always want to be one step ahead of where we are today. The drone industry’s progression would be similar to the ROV sector – the first ROVs put into the water were only designed for visual inspections, then their tasks were extended to other Non Destructive Testing (NDT) such as UT measurements and lately we are witnessing work class ROVs performing increasingly intricate maintenance work. Drones are in this second stage – the next steps are to develop tooling for maintenance purposes, and we will soon see painting and welding drones. Meanwhile subsea contractors are working on ROVs that stay permanently on the seafloor undertaking maintenance of subsea production equipment. This type of advance will happen for drones too within the next five to 10 years.”