Roland van Dort, Caledyne

High-pressure/high-temperature (HP/HT) wells bring with them integrity issues and in the case of mature or abandoned wells, difficulties in accessing untapped resources. These challenges have led to significant advances in downhole sealing technologies.

Traditionally, elastomer seals have led the way. Recently, however, an evolution in metal-to-metal seals has resulted in a seal design that not only meets demanding requirements, but avoids failures common to their elastomer counterparts.

A new retrievable metal-to-metal (MTM) downhole seal system addresses the challenges inherent in traditional elastomer seals, particularly shortcomings that arise during well suspensions and intervention operations. The new technology already has proven successful and could reinvigorate efforts to produce mature and challenging hydrocarbon reserves around the world.

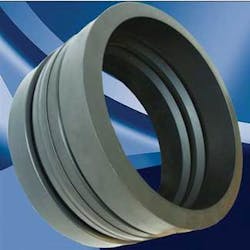

The MTM downhole seal developed by Caledyne consists of a flexible material contained in a metal shell. The structure creates a complete metal barrier in the well, and when fully energized, protects it from harsh downhole conditions. The system acts in a similar way to a standard elastomer seal, but is resistant to high hydrogen sulphide (H2S) and carbon dioxide (CO2) concentrations.

The MTM seal is designed to replace elastomer seals on existing downhole tools such as packers, bridge plugs and liner hangers.

The need for new technology

Performance rated to more than 10,000 psi (69 megapascals) at 572° F (300° C), the MTM seal can be installed on permanent and retrievable packers, bridge plugs, hanger packers, and subsea sealing applications such as crown plugs and flange seals.

Liner hanger seals are critical elements of the permanent pressure barriers of the well construction; so integrity is vital. The number of failures of critical hangers in North Sea HP/HT completions has become a cause for concern, and operators have been adopting rigorous quality assurance procedures for these pieces of equipment to prevent costly failures.

The MTM seal is certified to ISO14310, the international standard for downhole equipment in the oil and gas industry. It has the potential to supersede elastromeric packing element systems currently on the market because it removes temperature limitations and chemical compatibility concerns.

Field deployment

The first MTM seal installation on a liner hanger was performed at the end of 2006 in the North Sea. The seal was installed on a standard hanger packer to avoid swabbing issues and damage to the seal caused by drill cuttings while cleaning up the well. During the cleanup, well fluids were circulated at 8.5 bbl per minute without any adverse effect on the seal. A successful cement job followed the cleanup.

The seal was then energized with standard liner setting procedures and pressure tested. The liner hanger seal variant offers more reliable cleanup while circulating at high flow rate ensuring high quality cement jobs resulting in increased well integrity, without changing existing drilling operations.

The seals became commercially available in May 2007. Since then, there has been growing demand.

Installations scheduled to take place in Aug. 2007, included wells in the North Sea, Hungary, Kazakhstan, Canada, and the US and cover a range of applications including, HP/HT, steam flood, well abandonment, and as a solution to avoiding “swabbing” of elements.

The MTM seal has the potential to extend the life of mature fields in the North Sea and other regions while allowing operators easier access to heavy oil, which now accounts for the largest global reserves of hydrocarbon.

Unlocking the potential

As global oilfields mature and much of the easy oil has been produced, different techniques are needed to extract oil from the ground. Heavy oil in regions like Canada, California, Venezuela, the Middle East, the Netherlands, and CIS are fast becoming the focus of E&P operations.

The most common way of producing this type of oil is steam flood/steam drive, using temperatures of up to 300° C (572° F). High-temperature steam is injected in the wells, making the oil less viscous, which allows it to be pumped out of the wells. Standard elastomer seals tend to become less reliable and more prone to failure when temperatures are driven toward 300° C. With a standard temperature rating in excess of 300° C, MTM seals are better suited to high-temperature applications.

Well integrity issues

Mature oil and gas wells and abandoned wells are prone to various well integrity problems. An example is a long-abandoned well that has re-pressurized and has begun to leak through a cracked or poor cement job, creating the potential for an environmental disaster.

A recent survey by the Petroleum Safety Authority (PSA) Norway revealed that 18% of the wells studied in the Norwegian Continental Shelf exhibit some form of weakness/uncertainty regarding well integrity. Lack of well integrity can have disastrous safety consequences, with a blowout being the worst-case scenario, if the operator does not have a full overview of well condition at all times.

Mature or abandoned wells are susceptible to leaks and increases in pressure, which makes a reliable downhole seal even more crucial. Metal seals are preferable because they provide a complete metal barrier in the well. A metal barrier is extremely durable and reliable even with changing downhole conditions, which reduces the risk of environmental issues.