Spar platforms under review for marginal fields

The cell spar platform concept could be beneficial to small deepwater fields in the Norwegian sector, according to RWE-Dea Norge. The proposal arose from the search for a development solution for the Gjøa field, but could have wider relevance offshore Norway.

So far, take-up of the spar concept has been almost exclusively in the Gulf of Mexico, where it has proved a competitive solution for small fields in deep waters. “The Norwegian sector, and maybe the UK too, needs this kind of concept,” says Rune Taule, senior development engineer at RWE-Dea Norge.

After more than three decades of large-scale field developments dominating the Norwegian sector, the need to find solutions for marginal fields is becoming more pressing. Some of these fields are in waters too deep for a fixed platform, and also remote from infrastructure.

RWE-Dea’s proposal involves using spars in much shallower waters than has so far been the case. In the GoM the typically installation depth is more than 1,000 m. For potentially applicable fields in Norway, the depth is much less - Gjøa, for example, lies under 380 m of water. But when Taule and business development adviser Steinar Østli consulted specialist contractors in spar technology, they found that the notion of applying the concept to shallower waters had never been seriously considered.

One of the main benefits of a spar, Taule and Østli maintain, is that the oil and gas could be processed on the spar to meet GEFT guidelines (good enough for transportation) regarding specification and export in separate pipelines. It would thereby circumvent the often-serious flow assurance issues associated with transporting multiphase wellstreams from subsea facilities.

Behavior studies

Studies of how a spar would behave in conditions off Norway - taking into account wave characteristics, currents, and wind forces - produced favorable results. The movement characteristics of a cell spar platform looked to be more than satisfactory. “The crew would feel more comfortable on a spar platform than on other floating units,” Østli says.

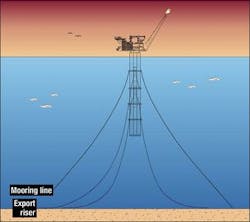

Another novelty in the duo’s proposal is the use of subsea wells connected to the platform by flexible risers. Spars are noted for accommodating dry wells, but different considerations apply off Norway, where the small number of wells on a typical marginal field does not justify putting a drilling rig on the platform. When Taule and Østli investigated use of flexible risers with a spar, the results were also positive. “We found that flexible risers are subject to less forces on a spar than on a semi or FPSO,” Østli says.

Construction experience for cell spar platforms also compares well with that for FPSOs and semisubmersibles. While spar platforms in the GoM have mostly been delivered at cost and on schedule, overruns are common on FPSO and semi projects in the North Sea. This situation may be sustainable on large field developments, but that is not the case with marginal fields.

The simple fabrication techniques associated with the spar, which consists typically of six or seven long cylindrical cells, one placed centrally and the others around it, are more suited to a marginal development than the typical FPSO or semi concept involving equipment on the topsides and in the hulls. And whereas the spar has few interfaces between topsides and hull, FPSOs and semis tend have many and complex interfaces.

In Norway there is the additional advantage that mating of the spar topsides and hull can be carried out in one of the deepwater fjords, and virtually all the hook-up performed inshore. For a Norwegian application, a spar platform would have a hull 150-200 m long topsides of 5-15,000 tons or more.

Gjøa challenges

RWE-Dea has proposed a cell spar solution for Gjøa, in which it has an 8% interest. Discovered in 1989, Gjøa is in blocks 35/9 and 36/7 on license PL 153 operated by Statoil. There is a significant uncertainty over the reserves. The mean estimate is 40.9 MMbbl of oil and 29 bcm of gas. Also, the field lies far from infrastructure. The nearest installations are the Troll platforms 70 km to the south and the Kvitebjørn platform about 90 km to the west.

“Gjøa is a complex reservoir, with not very large reserves, in relatively deepwater and relatively far from infrastructure,” says Østli. “It’s a challenge to make it commercial.” A varying gas/oil ratio over the field lifetime, a thin oil zone, early water breakthrough, and the very rich gas all add up to complex flow assurance issues in the event of a subsea solution.

After Taule and Østli had worked their proposal to an acceptable degree of feasibility, it was presented to the Gjøa license, which decided to take it onboard. It is now being evaluated along with other alternative FPSO and subsea concepts. A decision is expected later in the year.

Even if a cell spar is not selected for Gjøa, it seems certain the concept will be considered for other projects, given the strong interest the proposal has aroused in the Norwegian offshore industry. “We believe we can reduce costs if we bring this concept into Norway,” Taule says.