Gas turbine power solutions minimize weight, footprint on FPSOs

Lower costs, reduced emissions can also be realized

Eric Carlos,Siemens Oil & Gas, Americas

Optimizing thelifecycle performance of floating, production, storage, and offloading (FPSO) vessels is highly contingent on the incorporation of topsides packages that can efficiently and reliably deliver the power to exploit resources in a range of water depths and operating conditions. At the same time, offshore operators must be cognizant of the need to reduce emissions and minimize the weight and footprint of topsides modules, the latter of which can substantially impact facility development costs.

In recent years, advances in the design and engineering of critical equipment, such as gas turbines, electric motors, and compressors have helped the industry meet these demands. When coupled with digital solutions that are designed to leverage the power of data amassed from compression and other critical topsides assets, operators have been able to unlock hidden value and optimize production in a way that has previously not been possible. In addition to reducing capital expenditures, digital solutions enable remote operation with integrated automation and safety systems and can lower operating costs with reduced staffing, predictive analytics and integrated asset level optimization.

DATUM compressors deployed on an FPSO platform.(All images courtesy Siemens)

FPSO market

As the oil and gas industry continues to recover from one of its worst ever downturns, the market for FPSO vessels has followed suit. According to Energy Maritime Associates (EMA), 13 FPSO vessel contracts have been awarded since 4Q 2016[1]. This comes after a period of nearly two years without a single order. A total of three FPSO contracts have been awarded since the beginning of 2018, with an additional 10 that could potentially reach contract stage by year’s end.

Overall, the FPSO vessel market has experienced more robust growth than other offshore production facilities. This is largely due to the inherent advantages these facilities provide including increased operating flexibility in a wide range of water depths, fasttrack development, conversion possibilities, and storage capacity.

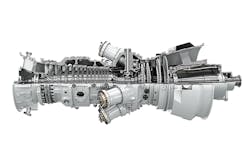

The SGT-750 gas turbine is designed to provide long maintenance intervals.

Power solutions

FPSO vessels have made it increasingly cost effective for operators to exploit oil and gas resources in deeper waters and harsher environments; however, their development presents many technical challenges with regards to topsides development.

In recent years, production equipment configurations have become more complex. This is particularly the case for FPSOs operating in sour field developments or where enhanced oil recovery techniques are utilized. On such projects, the need to implement optimized topsides configurations that minimize footprint and weight, while still meeting project requirements for processing, production, transportation, serviceability, reliability, etc. can be especially difficult.

Siemens has taken strategic steps to help the industry overcome these challenges by developing power and compression solutions that conserve weight and space, while providing the necessary horsepower to exploit deepwater reserves. The company has also launched an integrated digital solution designed to reduce FPSO project capex and opex, shorten development cycles, and minimize interfacing risk.

Over the course of the last year, the company was awarded contracts on four FPSO vessels. Details regarding the unique equipment packages that were provided, along with insight into operators’ requirements for each of the projects, are discussed below.

The SGT-A35 aeroderivative gas turbine incorporates a package design that is said to improve accessibility and serviceability.

Minimizing environmental impact

Siemens was selected to engineer, manufacture and commission the gas turbine-driven compression train for Equinor’s (formerly Statoil) FPSO vessel located in the Johan Castberg oilfield in the Barents Sea.

The equipment package includes a 41-MW SGT-750 gas turbine that will drive two high-efficiency DATUM compressors operating in a tandem arrangement. The turbine features a unique design that eliminates the need for a speed-increasing gearbox, which reduces the weight and footprint of the package. The compressors will reinject gas into the oil reservoir, providing pressurization and eliminating the need for capture or flaring, the latter of which is not permissible in the region.

A waste heat recovery unit will be supplied to recover gas turbine exhaust heat that will be distributed as a heated liquid to prevent ice build-up on key surfaces of the superstructure. Equinor’s selection of the SGT-750 turbine for the first offshore application in a production-critical service is telling of the technical assessment performed. The SGT-750 gas turbine was subject to extensive qualification testing to ensure the necessary levels of reliability and serviceability.

Equinor continues to seek solutions that will enable it to optimize production while minimizing environmental impacts. The SGT-750 gas turbine met project requirements for high power density, extended maintenance intervals (designed for 17 days in 17 years), and reliability, ensuring production uptime and profitability. The unique design of the compression train will help Equinor cost-effectively exploit the deepwater reservoir while reducing total CO2 emissions. Delivery for the equipment package is anticipated in mid-2019 with first oil planned for 2022.

Topsides 4.0 is designed to offer a holistic digital lifecycle approach to rotating equipment and electrical and automation systems.

Compression train design

Siemens recently delivered power generation and compression equipment for another FPSO vessel offshore Guyana in South America. The facility is the first oil and gas development project off the coast of Guyana. The equipment is scheduled for commissioning in late 2019.

Four SGT-A35 aeroderivative gas turbines were supplied for the FPSO vessel, each with a power output of 32.1 megawatts (MW). The SGT-A35 turbine utilizes a unique package design that provides accessibility and serviceability. This includes a lightweight torque-tube baseplate and internal jib crane that simplifies engine removal and installation.

The supply scope also includes three electric motor-driven compressor trains. Once commissioned on the FPSO, one electric motor-driven DATUM compressor train will reinject gas with a pressure up to 585 bar (8,485 psi) and the other two main gas compressor trains with a discharge pressure of 200 bar (2,900 psi) will compress the gas that is separated from the fluids in the topsides process up to the pressure required for the injection machine to compress the gas further to the required injection pressure.

Gas density is a critical parameter that affects a compressor’s stability and its ability to operate reliably. The compressors installed on this FPSO utilize technology that challenges the commonly accepted operating paradigm, making it possible for the compressors to become more stable with increasing pressure and density.

Siemens says it has been awarded contracts for power supply system, drives and integrated process solutions on four FPSO vessels in the last year.

An industry first

Siemens is also supplying four gas turbine power generation packages and two compressor packages for the FPSO Carioca MV30. The facility will be deployed in the Sépia field owned by Petrobras, located in the giant “pre-salt” region of the Santos basin approximately 250 km (155 mi) off the coast of Rio de Janeiro, Brazil. MODEC is responsible for engineering, constructing, mobilizing, installing, and operating the facility.

Power generation on the vessel will be achieved using four SGT-A35 aeroderivative gas turbine power generation packages. The SGT-A35 (formerly the Industrial RB211) will be coupled with an MT30 two-pole synchronous power turbine from the marine Trent engine, which will eliminate the need for a speed-decreasing gearbox. It will mark the first instance in which this configuration of engine and power turbine has been deployed worldwide. Two SGT-A35-driven DATUM compressor trains will also be installed to reinject CO2 to pressurize the reservoir at more than 250 bar (3,626 psi). These attributes make the packages uniquely suited for offshore FPSO applications, where space and weight are often limiting factors.

The equipment is scheduled for delivery in late 2018. As part of the agreement, Siemens will also provide service and maintenance for the supplied components over a period of 21 years.

Digital solutions for FPSOs enable remote operation with integrated automation and safety systems and can lower operating costs.

Electrification and digitization

Siemens will supply the full electrical and ICSS scope, together with four SGT-400 gas turbines, waste heat recovery units, a flash gas compressor, and two sales gas compressors for an FPSO in the eastern Mediterranean Sea. Commissioning of the facility is expected in the first half of 2021.

The equipment will produce both electricity and heat to extract and process the production in the open ocean, as well as export the gas to shore.

Unique to this FPSO is the first ever full-scale deployment of Topsides 4.0, which Siemens unveiled last year as part of a strategy to help offshore producers transition to fully digitalized operation.

Topsides 4.0 is a holistic digital lifecycle approach to rotating equipment and electrical and automation systems. It begins during the conceptual and design phase of a project and is designed to reduce capital and operating expenses, shorten project development cycles, minimize interfacing risk, and decrease offshore manpower requirements. Key features and capabilities that will enable these advantages include digital project management and manufacturing, virtual testing and commissioning, and delivery of an intelligent “digital twin” of the topsides facility, which can be used by operators for lifecycle decision-making support and asset optimization.

With the digital twin, engineers have continuous access to as-is asset data and can plan maintenance campaigns based on condition monitoring analytics. An integrated control and safety system solution is designed for remote control and monitoring so customers can improve safety and reduce costs by shifting labor resources from offshore to onshore. Combined, these benefits combined can reduce operating expenditures by more than 10% to 15% each year.

FPSOs remain critical

FPSO vessels are increasingly critical to cost-effective exploration and production of deepwater resources and in turn essential to meeting global hydrocarbon demand. To mitigate operational and financial risks—the latter exacerbated by cyclical market downturns—and to minimize environmental impact, FPSO projects require careful upfront planning and deployment of innovative power solutions that minimize weight, footprint, and emissions.

The application of integrated digital solutions that allow operators to leverage previously untapped equipment data has also proved effective in reducing FPSO vessel lifecycle costs and improving the overall economics of offshore production. •

The author

Eric Carlos is Vice President for Siemens Oil & Gas, Americas

References:

Floating Production Market Recovers in 2017 with Over $15 Billion in Orders. Energy Maritime Associates. April 2018.https://energymaritimeassociates.com/press/q2_2018_eng-3/