Nick Terdre

Contributing Editor

Aker Kværner Technology has completed the first phase of a production system comparison study for a leading operator in West Africa. This could lead ultimately to selection of a deepwater semi-subme-rsible production platform with top-side-comp-leted wells.

AKT made comparisons among the dry completion unit (DCU) semi, Spar, and tension-leg platform (TLP) concepts, and also compared a newbuild semi unit with a converted one. The company has no vested interest in promoting any one above the others, said Knut Sandvik, vice president for deepwater solutions.

All three floater concepts have been in service around the world, with varying benefits according to the setting. In a West African context, the DCU semi has one very significant advantage over Spars and TLPs, Sandvik said. It can be delivered to the field with a high degree of completion, regardless of the availability of local support services.

This is not the case with the other two concepts. Assembly of Spar platform demands a deepwater upending and mating site near the field and involves a complex set of support-intensive operations. Following mating and field installation, there is also substantial offshore hook-up work. Installation of a TLP also involves elaborate preparations.

Schedule benefits

While DCU semi concepts exist that include processing capability, there are advantages in using a pure wellhead unit delivering production after minimal processing to a nearby treatment facility. This is the scenario being examined in the current study, which has processing taking place on an FPSO.

There is potentially another significant benefit, Sandvik said. Time to first oil can be accelerated by having the semi carry out pre-drilling and tie-back of wells while the FPSO is being built or converted, thus enabling production to start as soon as the FPSO is installed and hooked up. In the pre-drilling period, the semi could employ rented power generation equipment, switching to power from the FPSO once the latter is in place.

Other advantages identified for the semi concept include:

- Plentiful operational experience with the concept, both for production and drilling applications

- Inherent flexibility, allowing ease of modification even late in the construction phase to accommodate new functional requirements

- Rules, regulations, and guidelines already in place

- Fabrication facilities available worldwide

- The concept has proven building blocks.

AKT is now beginning phase two of the study, examining in more detail potential for a bare-deck conversion compared with a purpose-built unit. The conversion concept offers the attraction of a schedule that is eight months shorter than for a newbuild, including a 10-month front-end engineering design period. Specifications include a unit with a displacement of at least 37,500 metric tons, operating in a water depth of 2,500 m and accommodating 12 dry wells.

null

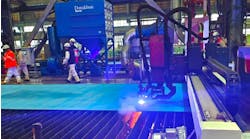

The basis for the conversion case is an existing Moss Maritime CS 50 bare-deck hull fully equipped with marine equipment and storage tanks for drilling consumables. This design, which has a displacement of 50,000 tons, has three columns on each side. Conversion work for the bare-deck hull includes the addition of structural steel for the tensioner deck, where the risers are held in tension with lateral support, and a superstructure above the main deck to provide wellhead overhead protection and support the skidbeams for the drilling equipment set (DES).

For the newbuild case, the basis is the Aker P45 concept, a four-column, parallel pontoon, flat-top design. A P45 was built and delivered in 27 months as a drilling and production floater for the Njord field offshore Norway.

Riser impact

The central design issue for the DCU semi relates to the support of the rigid riser system and its interface with the semi. Relative motion between the risers and the vessel must be reduced to a minimum. Action that might be taken includes optimization of the hull shape to minimize wave-induced heave motions, design of the mooring system to minimize horizontal excursions, design of the ballast system to ensure accurate control of the vessel operating draft, and division of the hull into compartments to avoid excessive setdown in the event of flooding of parts of the hull.

The rigid risers need to be top-tensioned to reduce lateral motion of the riser pipes and to avoid riser interference. The base case for phase one of the study has been Maritime Hydraulics' Ram Tensioner system, but alternatives will be considered in the next phase.

Arrangement of the wellbay is also important. All drilling operations are performed from a dedicated drilling center located in the center of the wellbay using a surface BOP and a dual-cased high-pressure drilling riser. The BOP is connected to the high-pressure drilling riser at the tree deck level and kept in tension in the same way as the production and injection risers. It can be lifted up to the DES substructure for storage and maintenance.

After a well has been drilled, the drilling riser is disconnected from the subsea wellhead and reconnected to the next well (assuming that casings in the top-hole sections of all the wells have initially been batch-set). The DES is then skidded to the relevant well slot to run the production riser and perform the final completion. This arrangement saves time through minimizing riser handling operations.