MATERIALS SCIENCE: PART I - 'Smart metals' providing actuation, sealing, and completion functions downhole

PART I: This is the first of a two-part series. Part I focuses on the theory behind shape metal alloys. Part II will feature the dozens of downhole well applications that are being made using 'smart metals.'

'Smart metals,' also known as shape metal alloys (SMA), are playing a growing role in supplying key actu-ation forces and sealing functions for surface and downhole equipment functions. A wide range of major oil and gas manufacturers have already installed smart metals in their equipment or are planning to do so.

Virtually every manufacturer using the technology is secretive about the process, seeking competitive advantage in the alloy's application. A large number of recent petroleum industry patents attest to the usefulness of the technology, although shape metal alloys with the desired characteristics have been around for decades.

What makes shaped metal alloys so valuable? According to Dr. Dimitris Lagoudas, Professor of Aerospace Engineering at Texas A&M University, the two prime functions of these smart metals are:

- Shape memory effect (SME): The ability to return to a predetermined shape when heated.

- Super-elasticity: The ability to return to a predetermined shape upon unloading.

"These two properties and others have made them attractive for use in electronics, medical, automotive, aerospace, and other miscellaneous applications," Dr. Lagoudas pointed out. He said the alloys possess adaptive capabilities in that they sense change in their environment (load or temperature) and respond accordingly.

The super-elastic effect was discovered originally in 1932 with gold-cadmium alloys. Shape memory effects were discovered in 1951, and Ni-Ti alloys (Nitinol) were used as early as 1962. Other metals added to Ni-Ti over the years include copper, iron, aluminum, gold, zinc, manganese, hafnium, lead, zirconium, and niobium, with different results. Some are still largely experimental.

Shape memory effect

The SMAs "memorize their original configuration after they have been deformed by heating the alloys above their characteristic transition temperatures, hence recovering large strains (shape memory effect)," Lagoudas explained. "The ability to sustain large forces and displacements, to alter their shape, to change their stiffness and damping characteristics with temp- erature or applied load, and the potential to act as compact powerful actuators, has made them excellent candidates for active or 'smart' structure applications."

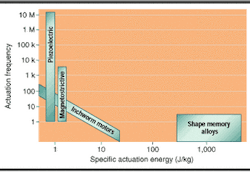

He said a wide variety of alloys exhibit shape memory effect, but "only those that can recover substantial amounts of strain or that generate significant force upon change shape are of commercial use." These include nickel-titanium (Ni-Ti) alloys and copper base alloys such as copper-zinc-aluminum (CuZnAl) and copper-aluminum-nickel (CuAlNi). In terms of petroleum industry applications, there are three key alloy manufacturing processes critical to the 'shape memory effect.' The metal is:

- Annealed in a certain shape (for example, a straight wire)

- Deformed when cold (for example, the wire is bent or twisted, or both)

- Heated, so that it will remember its original shape and return to it (for example, a wire becomes straight again).

Shape memory alloys have two phases in solid form: high temperature austenite and low temperature martensite. The physical properties of the two are different, especially in terms of yield strength. The martensite structure is easy to deform, a process known as detwinning. The austenite version can be deformed by dislocation generation.

"The austenite phase cannot accommodate detwinned martensite, so when detwinned martensite is heated and reverted to austenite, the deformation must be returned," stated a SMA study document released by Sintef, the Norwegian research group. "This reverse transformation is the reason for the shape memory effect."

There is a temperature range over which austenite and martensite co-exist. Generally, when martensite is formed, heat is liberated, and when austenite is formed, heat is absorbed. The transformation from one to another in each direction is temperature specific, and not the same. Applying stress affects the transformation temperature. Heat transfer for SMAs is achieved by radiation, conduction/convection, induction heating, and resistance heating.

Oilfield applications

Applications in the petroleum industry are limited by the types of alloys used, since each alloy type produces a different response. The limitations are expressed in three areas:

- Low maximum transformation temperature. This temperature for Ni-Ti alloys is about 100°C, but alloy additions have pushed this up to 200°C. However, according to the Sintef SMA research report, alloy additions such as nickel change the properties, so the search is continuing to find more desirable alloys.

- Poor mechanical properties at high temperature. Researchers are experimenting with Ni-Ti-Hf (addition of Hafnium), but little engineering data has been developed at this point.

- Poor mechanical properties when high transformation temperature is required.

Most of the viable oilfield applications have centered around three functions: valve actuation, packer/sealing techniques, and completions. According to the Sintef report, prospective examples of actuation for oilfield use are non-explosive setting tools, non-explosive release systems, downhole linear activation, sliding sleeve valve actuation, and formation testing.

Examples of sealing applications are high expandable casing patches, external casing sealing, mechanical sealing, and pre-perforated casing. Examples of connections are bold tensioning washers, self-tensioning bolts, composite riser coupling, large pipe coupling, multi-lateral connections, and cable anchors.

Patent applications

Oil and gas industry patents registered for applications of 'smart metal' technology include a wide range of actuation methods. For example, they include such functions as:

- Sealing the juncture between a vertical well and one or more horizontal wells using mandrels

- Locating and re-entering the junction between a vertical well and one or more horizontal wells

- Isolating one horizontal production zone in a multilateral well

- Locating and re-entering one or more horizontal wells using a whipstock with sealable bores

- Firing mechanism for actuating wellbore tools

- Wedge-set sealing flap for use in wellbores

- Downhole tool actuator

- Temperature compensated nuclear magnetic resonance

- Anchoring a device in a wellbore

- Hydrostatic setting tools

- Downhole tool motor.

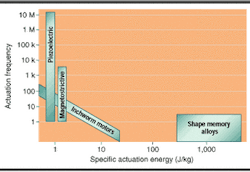

Actuation performance

One of the most successful applications of smart metals is that of actuation, which employs SME. In recent years, SMA actuators have replaced electromechanical actuators in certain areas because of their simplicity, deformation capability, compactness, and miniaturization potential with relatively high actuation energy.

One application being developed at Texas A&M University uses a fuel powered compact smart metal alloy system for actuation. A fuel such as propane can be used as readily as electrical power supplies. A Ni-Ti-Cu alloy (SMA) strip is embedded in a circular silicone tube. Convection heated and cooled water circulated by two pumps actuates the system, which can generate 150 MPa stress with 3% strain and 0.5 Hz actuation frequency. When heat is already present, the efficiency rises.

The SMA combustor actuator has much greater energy and power density compared to a battery powered electromechanical and linear motor actuator. In addition to actuation, SMAs can be used to isolation vibration. SMAs are pseudoelastic at room temperature, and deforming them causes them to transform into the martensitic phase. In the process, the SMA absorbs energy, producing a hysteretic res-ponse, which absorbs energy from the vibrating system.

Aerospace applications

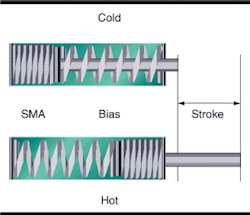

In the aerospace industry, SMA layers have been used with aluminum on the trailing edges of helicopter rotor blades. "Upon actuation, the trailing edge will bend, affecting the aerodynamics of the whole rotor blade, with the possibility of reducing turbulence and noise level," Lagourdas stated in an SMA applications paper. "SMAs have been used for active shape control, passive vibration damping, and active flexible rods."

Active biomimetic hydrofoils use SMA actuation to shape the foil to a desired form. In one foil application, the shape change formed a controlled oscillation (0.5-1 Hz) mimicking aquatic animals swimming.

Other aerospace applications include release devices for satellite and solar panel deployment and in vibration isolation. SMA researchers are looking at methods of smart capture and docking of space vehicles. Activation of the smart metal is usually obtained by cooling and heating the material, so there are some limitations in space use. However, the benefits include an almost zero-gravity action, in contrast to electrical engines, high/power volume (mass) density, and the fact that no dust particles are released and fluids aren't lost in the process.

Medical applications

One of the medical and orthodontic smart metal applications uses a form of SMA known as Nitinol (equatomic nickel and titanium), which has excellent torqueability and kink resistance and provides a constant force over a large strain range. This extraordinary flexibility and ability to return to the original shape when the load is removed is known as pseudoelasticity.

One medical SMA application, the pseudoelastic basket, would not be dissimilar to a mechanism used to fish bits and other objects out of the borehole. The basket is deployed through a cannula in a crushed form, then expanded into a basket to catch stones from kidneys, bladders, and bile ducts. After the particle is trapped in the basket, the basket returns to its original crushed shape and the particle is removed from the body.

"The transformation temperatures of the Nitinol can be adjusted to activate at the required temperature," Lagoudas stated. Some biomedical applications include those for pulmonary embolism, filters, vascular stents, tracheobronchial stents, urethral stents, bracing rods, and fracture fixtures. The stent is a woven shape memory metal to reinforce a passageway, and is not much different from an expanded tubular, lowered into a borehole to protect radius or seal off a production zone. ;

Acknowledgement

Contributing to this paper are Allen Gault, Senior Staff Engineer with Conoco ([email protected]); Dr. Richard Haut, Integrated Technologies Manager for Halliburton Deepwater ([email protected]); Dr. Hans Juvkam-Wold, Holt Chair Professor in the Department of Petroleum Engineering at Texas A&M University ([email protected]); Dr. Dimitris C. Lagoudas, Ford Professor of Aerospace Engineering with Texas A&M University ([email protected]): Dr. Dave Zimmerman, Professor of Engineering in the Mechanical Engineering Department at the University of Houston ([email protected]).

Reference

Lagoudas, D., (Untitled), not published.

SINTEF Petroleum Research; "Detailed study of shape memory alloys in oil well applications," 32.0924.00/ 01/99. Oslo, Norway.

SINTEF Petroleum Research; "Feasibility study of Shape Memory Alloys in Oil Well Applications," 32.0896.00/ 01/97. Oslo, Norway.

First Smart Metals Conference

The first smart metals conference, which will include theory and applications in the oil and gas industry, will be held on February 6, 2002 at the Houston Advanced Research Center (4800 Research Drive, The Woodlands, Texas) and is limited to 150 people (due to size of conference facilities).

The cost for attendance will be $50 per person, which includes breakfast buffet, box lunch, and one drink ticket for the closing social. Display booths will be allowed and will be open to those that cannot attend the full conference. To register for the conference, contact Traci Lopez (E-mail: [email protected]) (Tel: (US 281-575-3175) for an electronic regis-tration form and payment instructions.