Opinion: Industry seeing shift from reactivity to proactivity for safeguarding offshore crews

By Alan Finlay, Salunda

Measure twice, cut once. The classic adage is as relevant today as it ever has been, particularly in sectors where inaccuracy or a lack of situational awareness can have dramatic, or even potentially fatal, consequences.

When it comes to offshore safety, there is rarely a second chance. Hard hats and high-visibility clothing will always have their place in daily operations, but personal protective equipment, very often the last line of defense, is useless against a rolling pipe or falling fingerboard latch.

Offshore welfare is about more than mitigating slips and falls; it's about fostering a culture of awareness among crews and enhancing adherence to safety protocols.

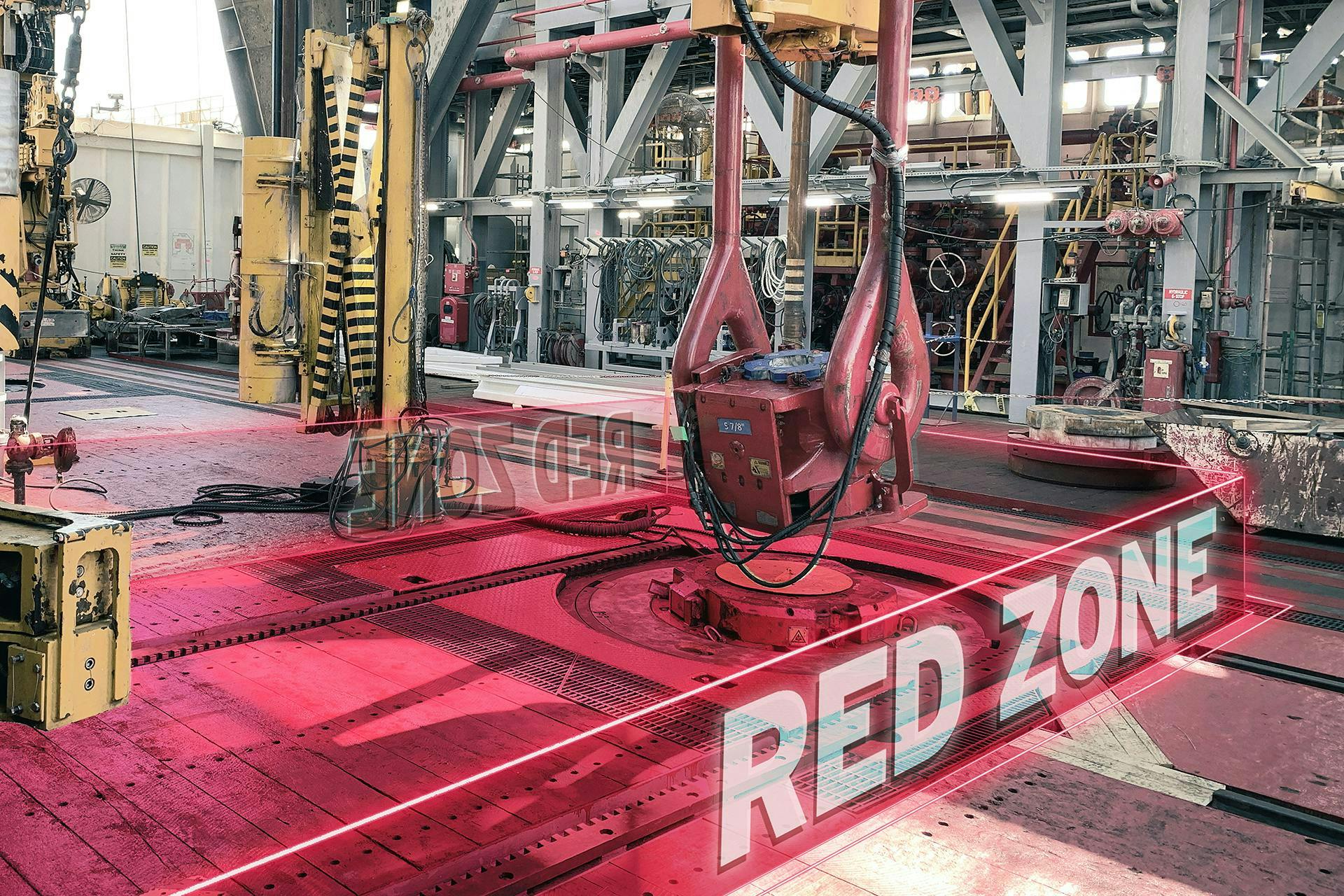

One of the most hazardous areas on any offshore installation is the "red zone," an area containing complex and moving machinery. It is imperative that all personnel working in these areas are acutely aware of the complex, dynamic risks present. Incidents within the red zone can result, at least, in operational downtime and can lead to fatalities at worst. This is where digital monitoring technologies come into their own, helping drive change and save lives.

A digital approach to safety

Humans are fallible, and digital technology is less so. A human spotter may miss a critical action or have a poor line of sight of a fellow crew member operating within a hazardous area, but digitized red zone monitoring tools have no such limitations.

These technologies combine wearable sensors and advanced 3D cameras to track personnel in real time as they move around working environments, enabling them to adapt to rapidly changing circumstances.

Drill floors and other designated areas are digitally mapped out, and hazards are identified and tagged with electronic geo-fences designed to trigger alarms if a boundary line is crossed. These monitoring tools inform the crew members and their area authority that they have entered a hazardous area, alerting them to a breach and prompting immediate corrective action to remove personnel from the line of fire. These devices can also be linked with the energized equipment in the red zone itself, pausing or halting machinery if a worker comes within proximity.

If an incident does unfortunately occur, the monitoring technology can be used to replay personnel movements, tracking workers who were close to or in the red zone, to establish a chain of events. This supports learning and knowledge-sharing across the industry, helping to shape best practice approaches to safety.

A culture shift

By leading the charge in adopting digital safety tools, operators can set new standards for red zone safety and signal a broader commitment to innovation and worker welfare across offshore operations, redefining what safety truly looks like offshore.

In recent years, the global uptake of technologies such as these has been an encouraging sight. There has been a transformative shift from reactivity to proactivity when it comes to safeguarding offshore crews. The tools industry workers once wished for, devices that can assess and identify real-time threats to personnel, are no longer hypothetical, and they can be used to prevent harm today.

By implementing the equipment, companies can foster a willingness to collaborate across the industry, as awareness of safety procedures is heightened and the number of procedural breaches are reduced, whether intentional or not.

Operators can capitalize on this momentum to set new benchmarks for red zone safety and apply this working methodology more widely within offshore installations, including well interventions and other activities where workers are exposed to hazardous or confined environments.

As Bill Gates once said, “The advance of technology is based on making it fit in so that you don't really even notice it, so it's part of everyday life.”

While the offshore industry will always involve risk to some extent, companies can make digitized safety technologies synonymous with life offshore as downtime is reduced, procedural compliance is strengthened and—most importantly—lives are saved.

About the Author

Alan Finlay

Alan Finlay is founder and CEO of Salunda Ltd.

Throughout his career, he has transformed loss-making, "concept companies" into profitable, globally trading groups through intensive business development, strategic marketing, innovation and commercialization of high technology. He grew Salunda Ltd., which specializes in safety-critical wireless equipment, industrial internet of things (IIoT), and personnel monitoring solutions in the offshore drilling marketplace.

Finlay trained as a mechanical engineer at the Engineering School at University College, Dublin and is a named inventor on more than 50 patents.