JIP addresses fatigue/buckling for deepwater HP/HT pipelines

David Bruton, Malcolm Carr - Atkins

As the industry progresses into deeper water, one emerging issue is how to design and safely operate the pipelines that carry hydrocarbons from subsea wells to the processing facilities.

The main challenge is that these pipelines want to buckle due to the compressive forces created by internal pressure and temperature. Historically, the industry trenches and buries pipelines to restrain them to prevent buckling. However, in deeper water, trenching and burying is less practical and with the higher pressures and temperatures often encountered in deepwater developments, this solution simply does not work. So now the pipeline is encouraged deliberately to buckle, but in a controlled way. By controlled initiation of lateral buckles at regular intervals, the loads are shared and reduced at each buckle site.

Early application of this idea was dogged by problems that have led to numerous failures, including three full-bore ruptures and one abandonment. All these incidents were caused by the issue not being addressed correctly in the design.

A related challenge is pipeline “walking” (gradual axial displacement of the whole pipeline with shutdown/restart cycles). It has been observed on several pipelines, in one case leading to system failure when the end connection ruptured. Various walking pipelines required subsea interventions to prevent failures.

To address these concerns Atkins launched an industry-funded Joint Industry Project (JIP) called “Safebuck”, to research all key aspects of deepwater pipeline design and to formulate both design guidance and new design tools. The aim is to reduce risk by gaining more confidence in the design methods and to improve the feasibility of these complex deepwater developments.

The JIP has assembled leaders in their various disciplines to contribute to the design guidance and research programs. The project team and supporting partners are Atkins, TWI, Cambridge University, and OTM, supported by Doosan Babcock, the University of Western Australia, NGI, Cathie Associates, and the University of Oxford.

Trigger mechanism

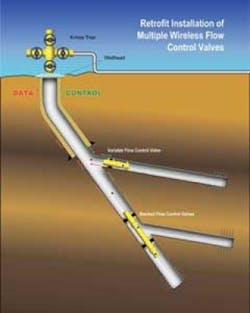

Safebuck has developed a method of deepwater pipeline design that encourages the deliberate formation of lateral buckles by pre-installing triggers at intervals along the pipeline.

The JIP has performed research into:

- Low-frequency, high-stress fatigue in corrosive environments. This design limit is driven by shutdown-restart cycles and is often the overriding design concern

- Local buckling of small-diameter pipe. To establish safe design limits for the most popular types of pipe used in deepwater developments

- Pipe soil interaction to evaluate lateral and axial pipe-soil response. This is the largest uncertainty faced in design and was investigated with an extensive set of small-scale and large-scale tests, many in soils collected from deepwater sites.

The assessment of fatigue in a lateral buckle has highlighted a key concern, because the fatigue loading is at a low frequency (a few hundred cycles over a 20-year design life). This combination of low frequency, corrosive environment, and a high stress range means fatigue life can be reduced by a factor of 10 or more.

When it comes to pipe soil interaction, the JIP pioneered the idea of testing this response at a very small-scale in a centrifuge, where the g-force can be increased to compensate for the small model pipe diameter. The advantage is that the tests can be done more quickly with less soil than conventional large-scale tests require. Large-scale tests still are needed, but the more we understand, the simpler these tests will become.

Safebuck addressed these and other design challenges for pipelines laid on the seabed that operate in the high-pressure/high-temperature (HP/HT) regime, where the significant loads in the pipe must be controlled to avoid failure and ensure long-term system integrity.

A third and final phase of Safebuck has recently launched. One chief aim is to collate performance data from operating pipelines that have been designed to laterally buckle, to improve understanding of how they behave, and to better address the design challenges encountered on recent projects. Another goal is to achieve a major advance in pipe soil modeling; this is so complex and critical to design that it must be simplified and made more robust. The models we are developing will be released to everyone involved in the JIP.

The key areas of work in this program are:

- Verification of the design method reliability with the aim of reducing unnecessary conservatism in design

- Collection and sharing of data and lessons learned from operating pipelines on recent projects without sharing sensitive project-specific data

- Formalization of the Safebuck Design Guideline into an Industry Recommended Practice.

Main areas of attention under the geotechnical scope are:

- The development of a new “force-resultant plasticity model” to run inside standard software packages to capture our experience from modeling and testing lateral pipe soil interaction. This approach will improve fundamentally the way lateral pipe-soil response is addressed in design

- A detailed review of axial friction response, based on recent project-specific tests, supplemented by additional JIP tests, to improve understanding and to quantify key uncertainties that influence cyclic expansion and pipe-walking.

Deepwater applications

The Safebuck JIP has gained industry-wide recognition, with participation from most major operators and pipeline installers, along with the US Minerals Management Service. The JIP also is endorsed by the UK’s Health & Safety Executive.

DNV joined the JIP earlier this year and is keen to work with the Safebuck team to capture the design issues the JIP has addressed – for instance, the DNV Recommended Practice RP-F114, which already references work published by the Safebuck.

Lateral buckle from seabed side scan survey.

The JIP’s technology has been adopted by its participants for most current international deepwater HP/HT developments off West Africa, the Gulf of Mexico, Brazil, Australia, the Caspian, and Indonesia, many of which are now in production.

Most of the novel test methods the JIP has developed have become industry accepted methods for project-specific testing. Also, the lessons learned from this research have improved the way laboratory testing is done.

One example is Fugro’s new deepwater pipe soil friction measurement tool, which applied lessons learned from the JIP laboratory tests, and which already has been deployed offshore Angola.

One aim of Safebuck was to raise money from industry to support the development of innovative technology, including research testing and development of design guidance. To date, the JIP has raised £1.15million ($1.77 million), with anticipated funding in the final phase taking the total to about £2 million ($3.1 million). The spirit of sharing knowledge and data within the JIP also has been strong, with participants donating data valued at around £3 million ($4.6 million) in estimated research costs.

Small-scale pipe soil tests in the centrifuge at the University of Western Australia.

Safebuck has saved costs in a variety of ways including shorter design times, avoidance of overly-conservative designs, reduced installation costs, and mitigating against operational issues and potential failures, with the obvious impact on production losses and the environment.

The intellectual property generated by the JIP includes the design guideline, the research results and design software written for the JIP, which is licensed to each participant for use on their own field developments. The software and the evolution of the design methodology was a significant investment for the JIP and are fundamental to the acceleration of the project design process and schedule. The design cycle for such development has reduced over the duration of the JIP, reducing the key aspects of the engineering design cycle from years to months.