Aramid hybrids ease strains on deepwater offload flowlines

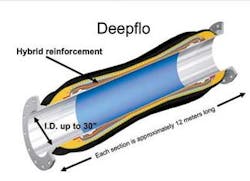

Hybrid materials based on aramid fibers are driving development of a new generation of smooth-bore flowlines with large internal diameters. Among these is Deepflo, produced and engineered by Dunlop Oil & Marine, which has been fully accredited to the industry standard API 17K (“Specification for Bonded Flexible Pipe”).

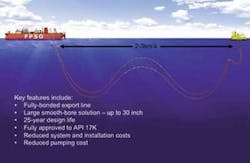

Deepflo flowlines are reinforced with a Twaron-based hybrid material, developed in cooperation with aramid specialists Teijin Aramid. The product has been developed in response to problems encountered by the industry while transporting sweet crude oil from FPSOs to floating buoys in mid- to deepwater, often over distances of several kilometers.

Until now, these transfers have been performed using flowlines designed for the very different job of pumping live crude oil up from subsea wells. But traditional flexible flowline designs often are restricted in diameter, do not have a smooth bore, and are heavy, which means the production has to be pumped under greater force and at greater cost. These difficulties have highlighted the need for a large-diameter flexible flowline that is not only strong enough to cope safely with huge dynamic stresses at sea, but is also lightweight.

Deepflo has a smooth internal surface and an internal diameter of up to 30 in. (76 cm). This allows higher volumes to be pumped at lower pressures, eliminating the need for booster pumps, and thereby generating savings in both capex and opex.

According to test results published by Dunlop, the Twaron-based reinforcement makes Deepflo lighter, stronger, and more flexible than traditional designs. The company claims that Deepflo hoses have a 25-year service life, can be safely operated with a working load of 200 tons (181 metric tons), and can withstand 100-year-storm conditions.

Weight gains

Dunlop recruited Teijin Aramid for this development, because, as Jason Aherne, manager of Teijin Aramid Oil & Gas, explains, no existing reinforcement material could fulfill the specific criteria on its own. “So we combined the strength of Twaron with the high elasticity of synthetic materials, producing a Twaron-based hybrid with a completely new set of properties.”

A conventional 24-in. (61 cm) flowline needs 16 layers of reinforcement, says Dr. Kambiez Zandiyeh, general manager of Dunlop Oil & Marine. “But because the Twaron-based hybrid is much stronger, Deepflo only needs half that many layers, allowing us to make huge gains in weight and performance, while reducing operating costs. The new hybrid provides us with exactly the right properties for FPSO-to-buoy transfers precisely because it was tailor-made for this application.”

Hybrid materials are under review for numerous other dynamic applications offshore. According to Aherne, “Aramid has a unique set of properties with a wide range of applications, but that doesn’t mean it always has the right combination of properties. By combining Twaron with other materials, we can ‘unlock’ the characteristics we want to take advantage of.”