ROVs advancing capabilities of compact ocean robotics

Editor's note: This article first appeared in the 2024 Remote Inspections & Operations Special Report, which published within the January/February 2024 issue of Offshore magazine.

Contributed by Curtis Lee, QYSEA

Advancements in subsea robotics and technologies, particularly within the realm of ROV/underwater robotics, have seen a significant surge. The development of increasingly compact, capable and autonomous systems has not only enhanced operational efficiencies but has also revolutionized data-collecting methods and improved working safety standards across the offshore industry. This evolution is particularly crucial in meeting the demanding needs of offshore inspections and maintenance of large subsea structures, where measurement precision, operational reliability and environmental adaptability are paramount for success in challenging underwater environments.

QYSEA Technology has developed advanced compact ROVs for non-destructive inspections. Its FIFISH AI Underwater Robots, a series of compact professional ROV solutions, are designed for advanced small-scale operations and inspections. FIFISH’s self-developed vector thruster system achieves 360-degree freedom in underwater mobility for the operator, allowing small robotics to be implemented for marine inspections, operations and explorations.

The robots range from small to medium-sized ROVs, all easily manageable by a single operator for offshore field work. QYSEA's autonomous technology aims to reduce human risks associated with traditional scuba diving in complex hydrological conditions around offshore platforms. The system enhances performance by providing a seamless operating experience with real-time feedback, addressing the dynamic demands of the industry.

AI-driven underwater inspections & operations

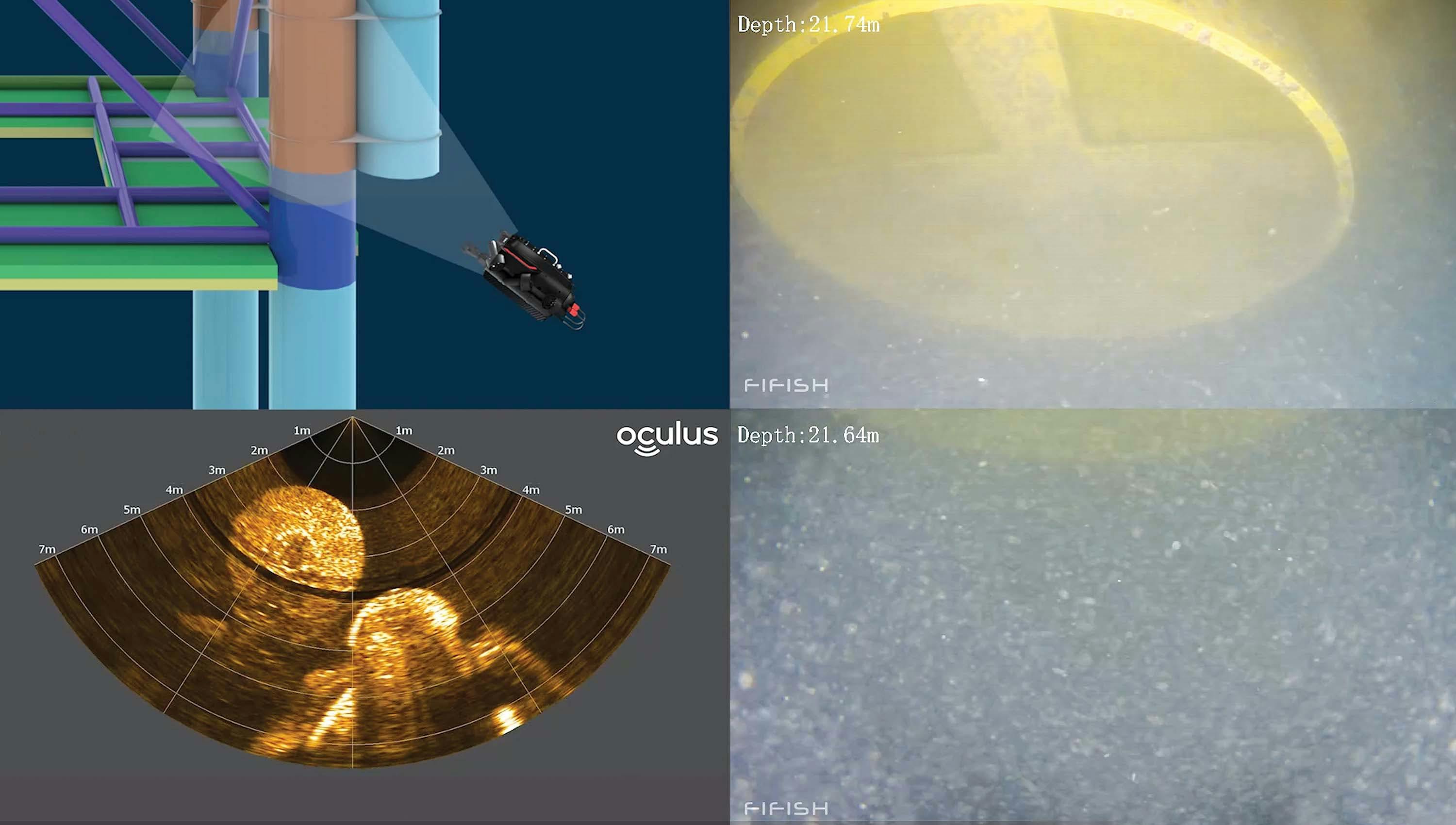

QYSEA's self-developed AI functions empower FIFISH Underwater Robots to adaptively lock onto target objects underwater with a touch control screen. The system enhances imaging clarity by mitigating underwater plankton and interferences, while also enabling precise measurements through augmented reality (AR) methods.

QYSEA's Vision Lock function facilitates adaptive stabilization and precise targeting of underwater objects with a touch control screen. Operators can concentrate on points of interest, ensuring stability during collaborative efforts with divers for tasks like inspection or damage assessment. The system integrates AI-powered diver and subject tracking, which is designed to enhance diver monitoring safety and facilitate prompt communication between divers and surface teams in offshore operations. This results in streamlined operations as well as improved safety, communication and data documentation.

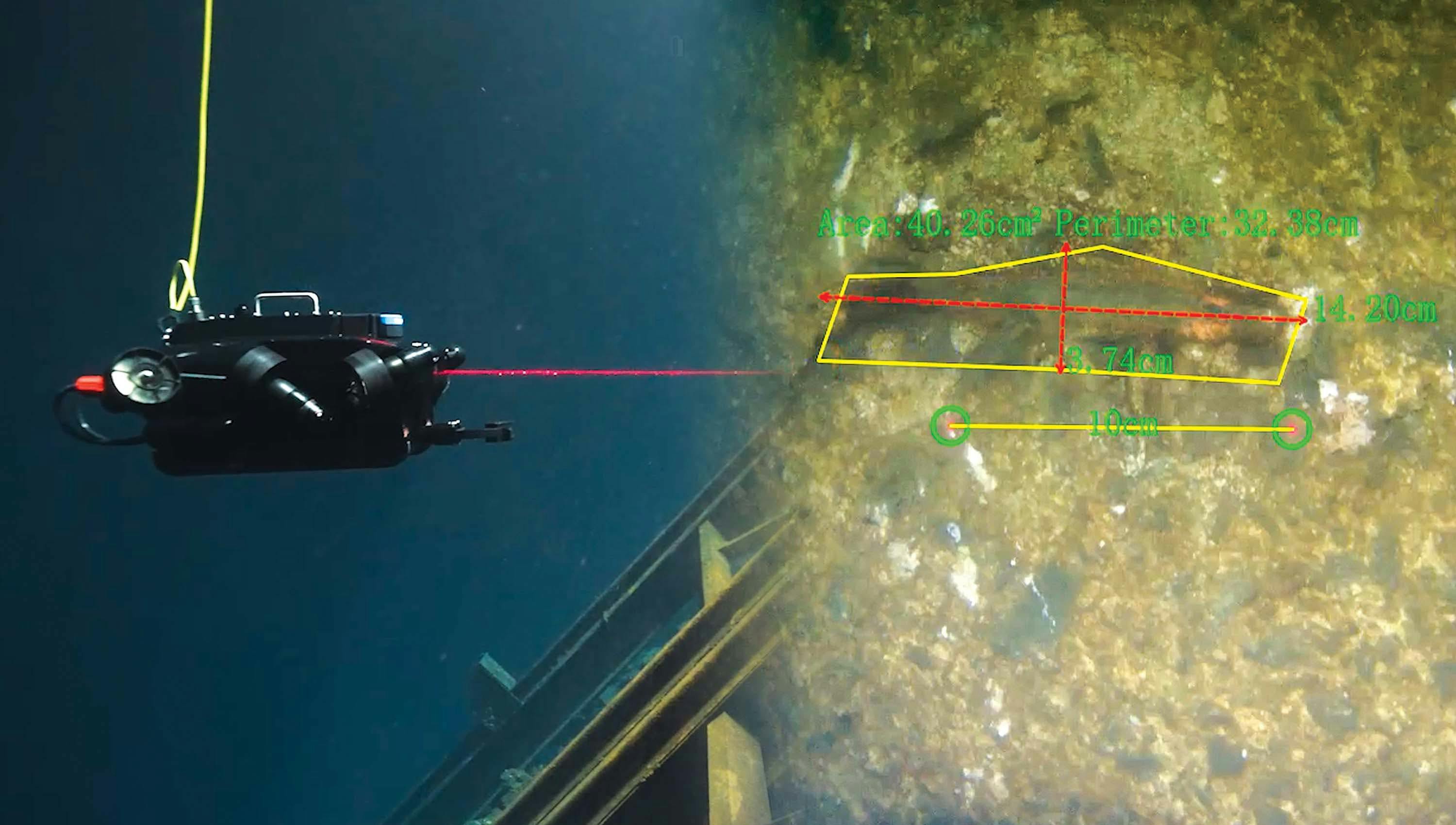

FIFISH also combines built-in or add-on traditional laser scaling equipment with AI automation to accurately and efficiently measure underwater dimensions of objects. This enables the identification of damaged areas in underwater structures, such as ship hulls, bridge pillars and wind farm structures, with precision.

Small-scale offshore operations

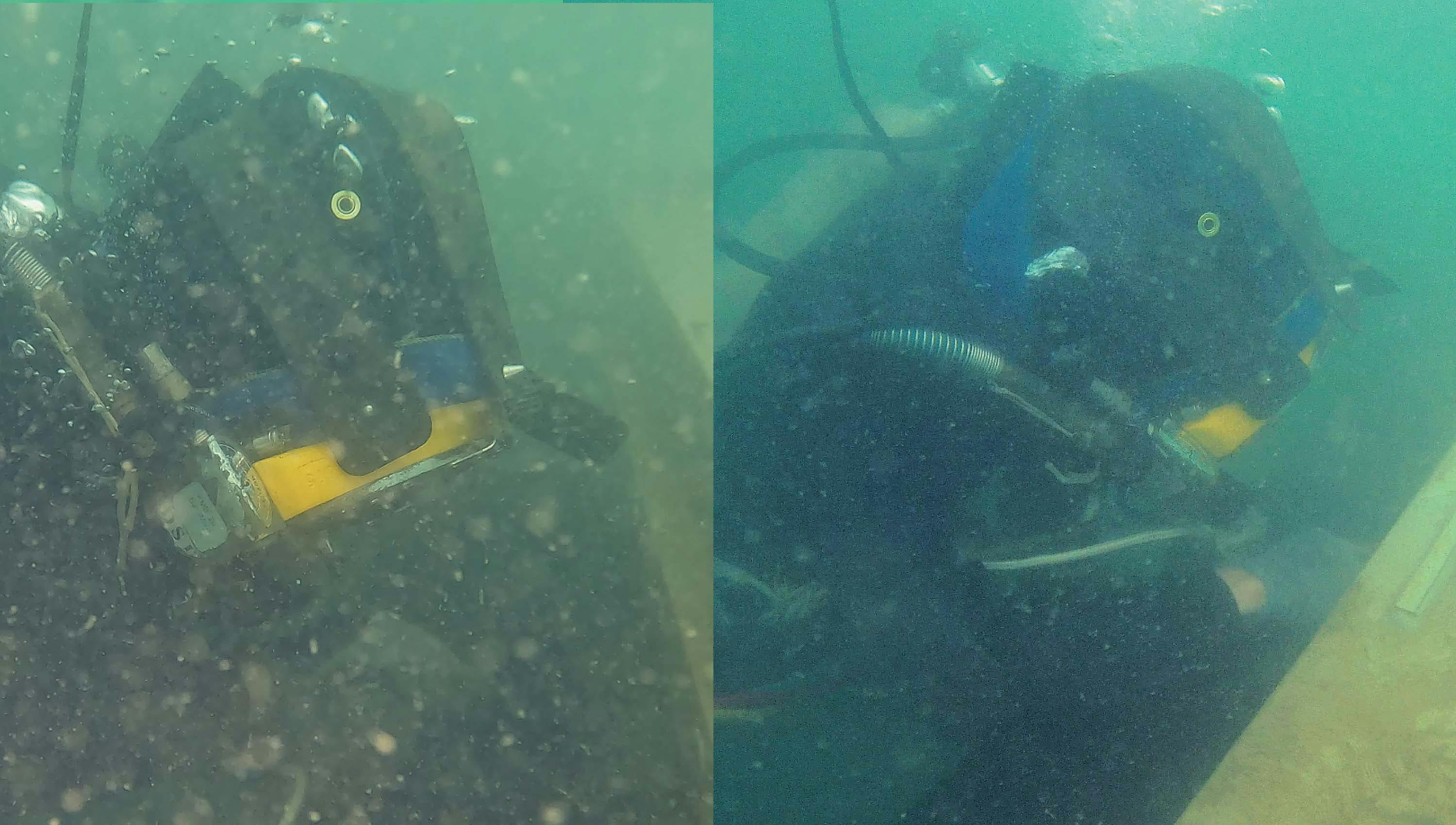

As wind energy leads the way of renewable energy resources, offshore wind farms across the worlds' coastal regions are seeing increased importance, requiring high operating efficiency and frequent maintenance. The installation of essential submarine cable systems—responsible for transmitting power between the turbines and power stations—are as efficient as ever through the operational tandem of the large-sized FIFISH PRO W6 and compact-sized FIFISH E-GO.