James Fisher completes modifications to North Sea Balmoral platform hull

Offshore staff

KNUTSFORD, UK – James Fisher Marine Services (JFMS) has completed a second inspection, repair and maintenance campaign for Premier Oil in the UK central North Sea.

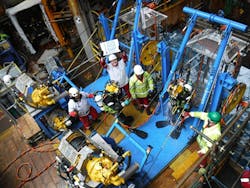

JFMS deployed a nitrox diving spread using gravity-based launch and recovery systems (LARS) installed on the Balmoral floating production vessel (FPV), 200 km (124 mi) northeast of Aberdeen.

The company used a Zone 2-rated nitrox system to directly extend dive times and increase productivity while simultaneously reducing manning levels.

Gordon Laurenson, subsea operations manager at Premier, said: “Completion of the scope has allowed us to extend the life of the facility, resolve a number of operational issues and obtain valuable inspection data for ongoing integrity management.”

JFMS’s dive crew were already familiar with the FPV and were able to incorporate prior learnings. In addition to complying with DNV GL’s underwater inspection in lieu of dry-docking (UWILD) requirements, various separate inspections, anode replacements and hull aperture blanking plate installations had to be performed.

Work from the FPV included diving through the platform’s moonpool and covered assets down to water depths up to 25 m (82 ft) lowest astronomical tide.

In total, the team undertook over 140 operational dives, spending a total of 225 hours underwater.

The project involved the installation of replacement anodes (~50 kg in water) on the underside of the pontoons, for which JFMS had previously designed and fabricated an installation/buoyancy frame to aid the diving team during this phase.

James Fisher Offshore supplied winches for tool deployment and recovery, and a specialist offshore technician to support the campaign.

08/20/2019