Technology venture looks to prevent flow assurance issues in Mexico's deepwater

Fernando C. Hernandez

SECC Oil and Gas Ltd.

Efrain Rodriguez-Sanchez • Nicolas Fuentes-Ruiz • Faustino Perez-Guerrero

Instituto Mexicano del Petróleo

Field Planning and Development

With the number of deepwater discoveries in theMexican sector of the Gulf of Mexico, it has been recognized that there is a need for enabling technology and solutions to be in place to prevent and remove hydrates from future fields that are to be developed. Failing to do so could disrupt or halt production. The need for solutions has accelerated with the enactment of Mexico’s energy reform in 2014; and the fact that Mexico has yet to begin deepwater production, where the threat of hydrates is omnipresent.

To this end, Instituto Mexicano del Petróleo (IMP) leveraged over 50 years of experience in dealing with Mexico’s offshore infrastructure, which includes its proficiency in the support of planneddeepwater E&P activities. This, in turn, ensures that technical and economically feasible production options for the fields are identified, assessed, and selected.

This experience has been paired with SECC’s global expertise in enhancing subsea production schemes in deepwater, via bespoke rigless and subsea intervention solutions. The result of this pairing: a reliable technical solution based on SECC’s technology and IMP’s collaboration for its implementation to disassociate hydrate blockages for future fields in Mexico’s deepwater frontier.

A secondary formidable threat - apart from hydrates - to the production of future fields comes from the natural decline of a well’s output. Further, this international collaboration led to an affirmation of the rigless production concept, which enables a DP-2 vessel to carry out flow assurance, hydrate remediation, and well stimulation maneuvers from a single access point on a manifold. This method differs from rigless interventions in that intervention equipment is not employed on trees.

More importantly, this collaboration discovered a way to retrofit future subsea assets that lack a strategic access point to carry out the aforementioned activities. This retrofit solution built upon work SECC undertook in the North Sea in 2014, which required unlocking of a manifold’s full potential at the field development stage.

Rigless production

In 2014, an operator in the North Sea required an innovative access point on a manifold that would enable them to have complete access to the subsea infrastructure. This access would provide them with the ability to stimulate all of the wells linked to a manifold without intervention equipment or a rig.

To create such an access point, SECC’s female rigless connector with emergency quick disconnect capabilities was preinstalled on a manifold at the build stage. Once the manifold was installed subsea and connected to its respective wells, this gave the operator instantaneous access to all the wet trees linked to a manifold. With this in place, at any point of the field’s life, the associated subsea trees can be independently stimulated to the tune of 16 b/min. through a 2-in. connector that is launched from a vessel via open water Coiled Tubing (CT). Some operators have achieved 56 b/min. through a 4-in. connector.

Furthermore, the manifold is outfitted with strategically installed valves that allow for intervention on a particular well while neighboring wells continue to produce. Once the aforementioned well has successfully been intervened, a neighboring well is then stimulated, while the first stimulated well begins to produce alongside the other wells.

This field-proven methodology is highly applicable to maintaining positive levels of production in Mexico’s future fields, and having a well enhancement program in place months and years in advance before first oil.

Flow assurance

Taking this one step further, IMP and SECC concluded that the rigless production approach, with the inclusion of strategic access point on a manifold, held immense benefit in regards to flow assurance and hydrate remediation operations. Such benefits are due to the fact that not all fields have strategic access points for the injection of chemicals or inhibitors for flow assurance purposes.

The rigless production method allows a vessel to safely connect to a manifold and inject chemicals and inhibitors at barrels per minute through an entire field. This approach serves as a highly redundant method of introducing chemicals and inhibitors when a field’s umbilicals have malfunctioned; or should the umbilicals fail to deliver the proper volumes to prevent hydrates from forming. The reason a vessel is able to disconnect safely is due to the fact that SECC’s connectors autonomously disconnect in an emergency, independent of any human interaction, should a vessel have a catastrophic failure. Accumulators, acoustics, or ROV manipulation of valves is not needed.

All that is required for a disconnection to occur is for the male connector to sense a pull/tension from a downline attached to the CT. Once the male is disconnected, both male and female ends self-seal, while holding up to 15,000 psi at each end. This prevents the contents within the CT to be expelled into the ocean, while equally ensuring that the subsea well is sealed.

Combating hydrate formation

When a hydrate blockage has formed, a vessel, by way of its topsides pumps, can bullhead against a blockage by pumping against it so as to physically dislodge it; or by soaking a blockage to disassociate it. However, such techniques do not guarantee the removal of a hydrate from a field or from an export line. Sequence wise, these techniques are the critical first steps when attempting to remove hydrates.

IMP presented the following forward-thinking questions: What if a manifold installed in Mexican waters was not outfitted with a rigless connector, so as to inject chemicals and inhibitors at high flow rates through an entire field? Could the technology be retrofitted without bringing it to surface, so as to also enable a vessel to interface directly with a manifold? Would it be possible to modify SECC’s connector technology to allow for an ROV and subsea hydrate remediation equipment to tie directly to SECC’s female connector via an intervention panel? The answer to the aforementioned is highlighted in the ensuing sections.

Retrofit solution

IMP and SECC extensively analyzed deepwater field layouts, and it was discovered that in various fields throughout the globe, spare hubs were available for future subsea tiebacks, and often went unused. These spare hubs created the opportunity to retrofit a manifold, allowing for the rigless production method to be employed.

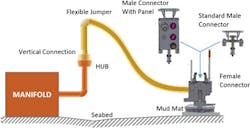

To accomplish this, SECC’s female rigless connector is landed on a mud mat, along with a flexible jumper. The flexible jumper is then mated with the manifold at the hub via a running tool. A flexible jumper is used, since it bypasses having to conduct any metrology operations as is the case with ridged jumpers; and a flexible jumper also allows this configuration to be installed in different manifolds throughout a field. Once the running tool securely locks the jumper to the hub, and pressure and integrity tests have been conducted, SECC’s male connector - with no intervention panel - can inject chemicals and inhibitors through an entire field and its export lines.

However, this raised an additional question: What if all the hubs on a manifold are used - how will an access point be created? Due to the fact that no deepwater fields have come online in Mexico’s deepwater realm, the following are recommended practices for the future where:

- A minimum of one spare hub is available for two manifolds that connect to each other, or one spare hub if only one manifold is brought online

- The manifold has access to all the flowlines and export lines (via valve arrangements) for flow assurance operations

- That said valve arrangement allows for well interventions to be carried out on all the wells linked to it.

It should be noted that in 2013 an operator required an intervention on a horizontal tree offshore West Africa; and that SECC’s female rigless connectors were deployed via a mud mat system. This project is mentioned because it demonstrates that the configuration suggested for Mexican waters has been executed by SECC, in terms of using female connectors on the seabed.

Hydrate remediation

As previously stated, injecting chemicals or inhibitors does not guarantee the removal of hydrate blockages. For this reason, SECC’s connectors, with the guidance of IMP, are now being designed to incorporate intervention panels with hot stabs and paddle valves. In this context they are no longer being used to solely connect to a downline via CT. This allows for an ROV to methodically connect hydrate remediation equipment directly to said panel. By adhering to the three recommended practices mentioned above, depressurization activities can be executed throughout an entire field, and respective export lines.

Although manifolds may include hot stabs for remediation activities, analysis of global infrastructure shows that they may not always be fit for purpose, as highlighted by attempting to remove hydrates through an API 17h hot stab. However, due to their porting size, this severely restricts the removal of a pipeline’s content at high flowrates during depressurization activities, especially when removing several kilometers of gas, water, and other fluids.

For this reason, the intervention panel that sits atop of the connector is outfitted with SECC’s Max Flow hot stab that has a through bore of 1.5 in., which is conducive to removing a pipeline’s content at high flowrates. Moreover, the panel is outfitted with an additional hot stab dedicated for treating the hydrates that are being removed with methanol during depressurization activities. Integral paddle valves allow for the incoming methanol to be intelligently routed to the Max Flow stab, to ensure the hydrates are inhibited (during dosing operations, methanol does not enter the pipeline).

Importance of dosing

The dosing technique is key in reducing downtime while increasing the effectiveness of any hydrate remediation campaign. Dosing allays the hydrate formation phenomenon in which hydrates shift, migrate, and reform dynamically when removed from the pipeline, without being treated. Because of this, removing hydrates through a hot stab on a subsea asset is not recommended, as these hydrates cannot be dosed.

Further, should a blockage re-form, this will affect all of the subsea equipment being used to remove the blockages.

After a hydrate has been successfully removed, the intervention panel is detached, and the male connector is attached to the CT, and mated with the female connector so as to inject inhibitors. This action is designed to prevent hydrates from reforming once the producing wells are brought back online.

Conclusion

The threat of hydrate formation and pipeline blockages is a technological challenge that has been considered for Mexico’s deepwater fields. As illustrated herein, a most cost-effective feasible solution to mitigate and disassociate hydrate blockages has been conceptually designed by SECC and IMP. This solution is all encompassing, since it can be implemented at the build stage, or should subsea manifolds need to be retrofitted. Moreover, the rigless production method equally provides a method to increase production from wells where output has decreased.