Shell drills record tieback well to counter sand, watercut problems

148 MMcf/d production saves Mensa

William Furlow

Editor-in-Chief

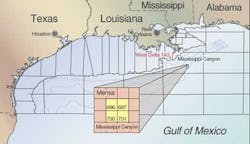

The Mensa field in the Gulf of Mexico has long held the record for the world's longest subsea tieback, 68 mi. Located in 5,300-ft water depth, the three Mensa wells account for 10% of Shell's gas production in the Gulf of Mexico.

Joe Leimkuhler, subsea development manager for Shell Exploration & Production Co., said the Mensa system is designed with a maximum throughput of 300 MMcf/d and requires a little over 100 MMcf/d to maintain flow assurance and support the cost of the operation.

The Mensa A-1, A-2, and A-3 wells have been in production since 1997. They are situated in Mississippi Canyon blocks 686, 687, 730, and 731. Each well is tied back via a 5-mi jumper to a subsea manifold. There, the production is combined and sent through a 12-in. pipeline to the West Delta block 143 platform 63 mi away.

The formations Mensa is producing from are in the Upper Miocene I sand, about 15,500 ft below the mudline. These are very young formations, Leimkuhler said, consisting mainly of unconsolidated sands. As large amounts of gas are removed from these fields, this sand begins to compact, which puts added loads on the completions and tubulars used in the three production wells.

Over the last two years, the A2 well, which is in the deepest water of the three, began to produce sand. Leimkuhler said studies by Shell showed that the reservoir compaction is the probable cause of the A-2 sand production, and other wells, especially the A-3 well, were under similar compaction risk. As it stood, A-2 had to be choked back to reduce the sand production.

An additional risk to Mensa is potential water production. Mensa is probably a combination compaction/water-drive reservoir, once the water hits the most down-dip wells (A-3), they will be shut in due to the risk of hydrate formation. With the depth of these wells and the volumes of gas moving through the systems, Leimkuhler said it would be impractical to use flow assurance chemicals to address the water cut/hydrate issues. If the water were to invade, the well would have to be abandoned.

A-4 well

Shell decided to drill an additional, high-capacity well up-dip from the water face and relieve some of the compaction risk from the existing production wells. This needed to be done quickly, with one of the three wells already crippled by sand production. If another well ran into problems, the field could fall below the 100 MMcf/d economic threshold.

In November of 2002, the Transocean Deep-water Nautilus drilled the Mensa A-4 well. This well had a larger, 5 1/2-in. completion designed to handle greater production volumes. While all the trees designed for the original Mensa were one-offs, Shell has since standardized its tree design.

There was some discussion prior to the drilling of A-4 about whether the A-4 christmas tree should follow the original Mensa model or take advantage of less expensive, fast-track standardized designs. Leimkuhler said it is fortunate, in retrospect, that the standardized design was chosen because the only delay in the completion was a wait on the tree equipment. He said existing backorders for a non-standardized "Mensa" tree could have meant further delays. The standardized tree was specially equipped to be used with the existing Mensa controls system.

Because this well has a 5 1/2-in. tubing size, Leimkuhler said it would be capable of meeting the 100-MMcf/d requirements of the field by itself. In fact, the flow of this one well would be capable of producing much more, but was restricted by the erosional velocity of the gas through the tree.

It was much easier to drill this fourth well than it had been to drill the first three Mensa wells because of the lessons learned from the offset Mensa well. The sweet spot of the reservoir was identified and the well was placed far up-dip from the suspected water movement.

null

Drilling and completing

While the actual drilling and completing of the well were simplified, Leimkuhler said there were some unusual challenges with the rig. Prior to completing the well, the Deepwater Nautilus was moved 40 mi from the Na Kika site to Mensa without pulling the riser and subsea BOP. While the goal was to accelerate the completion time on this project, Leimkuhler said the real savings was not in running time, but in surface handling/prep time for the BOP system. He calculates four to five days were saved due to this choice.

Still, because the tree was not ready when the well was drilled, there was a delay in the completion operation. A different rig had to be brought in for the completion because the Deepwater Nautilus was drilling on another well site.

Clean up

Despite this delay, the well came online with first production in March 2003. Once the well was completed, the Shell team had another tough decision to make. All of the completion materials, completion brines, spent acid, frac fluid, and other materials associated with completing the well had to be unloaded.

There were two options. The well could be unloaded back to the completion rig, requiring the associated gas to be flared. Leimkuhler said such a high volume of gas would account for 10% of Shell's 2003 flare gas target for the Gulf of Mexico, clearly undesirable. The other option was to run all of these materials through the Mensa tieback, 68 mi to West Delta block 143, where it could be processed.

In addition to the completion fluids, parafins, heavies, and condensate had built up in the system over the previous years at the lower flow rates. Leimkuhler said he was nervous about this because if the main flowline were to become damaged, or clogged by a hydrate, it would mean a costly shut-in.

The engineering team ran calculations, evaluated the risk, and determined that these materials could safely flow through the line to the host. The decision was made to unload the well to West Delta block 143. Leimkuhler said the process was successful, avoiding the need to flare the gas and effectively cleaning out the well.

After the initial clean-up and flow period, the new well was then shut for a pressure-build test, followed by a series of flow tests. The well tested at a Gulf of Mexico record flow rate of 148 MMcf/d.

While it could flow faster, Leimkuhler said the well is choked back to limit the stress on the completion and optimize the drawdown among the other wells in the field. He said the well could be brought up to as much as 160 MMcf/d, but moving beyond that would put the tree at risk. While this would break another well-test record, Leimkuhler said Shell will most likely wait a few months before performing another well test on A-4 because of the associated cost.

Back in the 300s

Thanks to A-4, the production rate of Mensa is back to 300 MMcf/d. The new well has also decreased the load on the other three Mensa wells, extending their lives. Although the A-3 well is now producing some sand, Leimkuhler said the four wells together should maintain the 290-300 MMcf/d target for the field.

Because the A-4 well produces through 5 1/2-in. tubulars and an 8-in. jumper compared to the 4 1/2-in. tubulars and 6-in. jumpers on the other wells, it requires less reservoir energy to produce at high rates. Leimkuhler said this is a key component in extending the overall life of the field and increasing the reserve estimates. With A-4, the total gross recovery of Mensa has been bumped up to 770 bcf.

Looking ahead, Leimkuhler said Shell hopes that sand compaction, rather than water is the primary driver for the field depletion. Only time will tell, but if this is the case, it will be good news for the reserves estimate. He said the wells could continue producing in to the future, even at very low pressures, if the gas is being driven by depletion/sand compaction.

On the other hand, if water turns out to be the driver, then it is possible some of the wells might water out before reaching their ultimate potential. Regardless, 68 mi is a long way to drive gas, and Leimkuhler said it is likely the system will require either suction compression on West Delta block 143, or possibly a subsea booster pump to drive production up the hill to West Delta block 143.