Assessing the state of arctic technology development

G. Abdel Ghoneim, P.E., Ph.D.

Det Norske Veritas

Sooner or later, petroleum development of the Arctic Circle will take place. The technology exists today to safely and reliably develop the 25% of world oil and gas untapped reserves that exist there. The challenges associated with the design and operation of arctic exploration and production installations are many, and have been discussed exhaustively in the past.

The goal here is to assess the current status of these challenges and to review the use of recent ice rules and standards in the design of fixed and floating arctic structures. The development of new DNV design guidelines on ice structure interaction is also discussed. That work will be completed in 2011 or early 2012. The project is based on the new ISO 19906 standard, and covers both fixed and floating installations.

Finally, a number of past and recently proposed arctic development concepts, as well as some new untested ideas, are reviewed. It is noted that some concepts may not be feasible and may carry heavy risks, while others are quite feasible but may be prohibitively expensive. Balanced concepts are sought and presented.

Arctic structures

There has been considerable experience gained through construction and operation of arctic climate structures in the US Cook Inlet, Canadian and US Beaufort Sea, Russian Sakhalin, and Canadian East Coast. There also has been considerable R&D work carried out on ice mechanics, ice structure interaction, and operational safety and environmental protection. TheExxon Valdez oil spill and the Deepwater Horizon/Macondo accident clearly demonstrate the significance of the human factor, even when the technology is thought to be “perfect.” Now attention is focused on preparedness and the development of ready-to-implement contingency plans in the event of such unexpected events. These efforts will also be applicable (with some adaptation) to arctic E&P developments.

It is worth noting that in the 1970s it was rare to find ice and arctic specialists, whereas now it is not uncommon to see young engineers pursuing careers in arctic-related fields and completing higher education like M.Sc. and Ph.D. degrees from prominent Russian, U.S., Norwegian, Canadian, and other universities.

The knowledge available today probably is adequate to design, construct, operate, and maintain an E&P structure in the Arctic Ocean on a year-round basis with safety levels that meet or exceed requirements currently adopted offshore in the Gulf of Mexico, the North Sea, the South China Sea, or West Africa. It is possible to demonstrate that such technology is reliable and effective. The cooperation and commitment of all stakeholders is necessary in order to get arctic development on its way towards a safe, environmentally sensitive, and reliable future.

The focus here is on arctic exploration and production structures. Technologies related to arctic shipping, pipeline/tanker transportation, ice management, and geotechnical issues are not addressed.

Arctic challenges

Twenty arctic challenges are identified and tabulated (see “Arctic Challenges” table; Ghoneim, et al., 2010). They are given a significance ranking ranging from 1-4 (1 being most significant) with a status in percentage of where the technology is thought to be at present versus the desired situation. The estimates given are based on the judgment of the author.

Experience with other offshore areas such as the Gulf of Mexico, the North Sea, and West Africa where operations have been carried out successfully in harsh environments for many years and in deep waters indicate that the above level of competence for the Arctic is of similar level of reliability. Further assessment may be necessary to quantitatively make this comparison.

Arctic concepts

Several concepts for arctic drilling and production systems are being promoted for application in the promising areas for future development. The concepts include drillships for year-round operation, jackups, production spars, gravity-based structures, FPSOs, and floating structures. A number of arctic spar concepts have been proposed by Sablok and Barras (2009) and Murray and Yang (2009). The spars are disconnectable upon encounter of ice features that exceed their design limitations and could be constructed of steel or concrete.

An MMS (now Bureau of Ocean Energy Management, Regulation, and Enforcement or BOEMRE) research study by IMV Projects Atlantic Inc. (IMVPA, 2008) gives an extensive account of the technology status with regards to E&P options for application in cold regions such as the Beaufort Sea, the Chukchi Sea, and the Bering Sea. Bottom-founded fixed platforms, floaters, terminals, pipelines, and subsea options are discussed.

In 1997, 2004, and 2005, three proposed arctic concepts and a more recent jackup type design were proposed for Sakhalin II by Gunningham, et al. (2008). A bottom-founded stepped type gravity-based structure in about 100 m (328 ft) of water was proposed for the Grand Banks offshore Newfoundland by Fitzpatrick, and Kennedy (1997). The second is an earlier spar concept proposed by Murray (2004); it has a disconnect feature allowing it to be towed away quickly upon threat of an approaching iceberg. The third is an arctic semi-rigid floater originally designed for Sakhalin Island by CKJ Engineering (2005) for 80 to 500 m (262 to 1,640 ft) water depth. Not much detail is given for the arctic jackup concept in Gunningham, et. al. (2008). It is only stated that the concept is under investigation. A US patent application for an arctic year-round drilling jackup design by Brinkman and Davenport (2010) has also been submitted.

The gravity-based structures are suited for up to 100 m water depth in regions with multiyear (MY) ice and to 150 m (492 ft) in first year (FY) ice, respectively. Jacket and jackup type platforms are feasible to water depth of about 60 m (196 ft) in regions like Cook Inlet and the Bering Sea, but may not be suitable for the Beaufort or Chukchi seas. It is possible to construct ice or gravel islands for up to about 12 m (39 ft) water depth. Gravel islands may not be suited for the Chukchi Sea’s more dynamic conditions compared to the Beaufort Sea.

The IMVPA (2008) study also states that floating structures are not feasible for the Beaufort, Chukchi, or North Bering seas, even with ice management. Therefore, only Bering Sea-like conditions may be tolerated year-round by floaters that have the capability to disconnect in severe conditions. Subsea systems are feasible in regions with sufficient water depth to avoid ice interaction or with provision of glory holes to house the system with tiebacks of 170 km (105 mi) for gas and 65 km (40 mi) for oil production. The choice of an appropriate exploration or production system does not only depend on water depth and ice conditions, but also on the ice management and disconnect capabilities commensurate with the arctic region under consideration. The risks associated with the operation and the consequences of failures have to be quantified and understood.

All the concepts presented above are (in this author’s opinion) feasible and balanced with regards to cost and risk management during design, construction, installation, operation, and decommissioning. Additional studies are however recommended to address site specific conditions and logistics.

Design philosophy

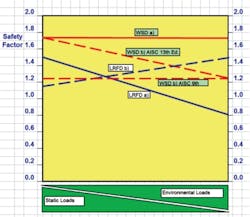

Two methods normally are employed in design; namely, the limit states load and resistance factor design (LRFD) and the working or allowable stress design (WSD or ASD). The differences between the two methods depend on the magnitude of the environmental load relative to the permanent load. The allowable stresses are increased by a third when extreme loads are applied. The AISC, 2005 13th Edition Steel Construction Manual has discontinued this practice by only allowing the one-third increase on the portion of the stress caused by the variable and environmental loads. No increase is allowed for the permanent or dead-load effects. Notably, the Manual now includes both the ASD and the LRFD design methods in the same document. The comparison made here shows that as the environmental loads increase relative to the gravity loads, the LRFD methodology becomes more appropriate with regards to the safety factor. The a) and b) notations refer to the operating and extreme load conditions, respectively. It is therefore recommended that the design of arctic structures be based on the LRFD method rather than the customary WSD employed so far in the design of US Gulf of Mexico offshore structures and adopted by most API specs and RPs.

Earlier arctic concepts.

ICESTRUCT JIP

This DNV joint industry project is studying the effects of ice on arctic offshore structures. It aims to present a common and documented approach to achieve acceptable safety levels for offshore structure designs in cold climate regions, by adhering to the normative provision of the ISO 19906 standard issued in December 2010, and by supplementing it through the provision of practical design recommendations and case studies.

In close dialogue with the ISO Working Group responsible for ISO19906, DNV is developing a companion document to the ISO standard in the form of a Technical Guideline (which may be turned into a DNV Recommended Practice in the near future). The Guideline should be considered a supplement to the Informative provisions of ISO19906, providing practical design recommendations, limitations, and case studies (Cammaert and Horn, 2009).

An initial gap analysis highlighted areas where additional research was warranted. One of the areas to be covered in the project guideline is ice effects on floating structures, which has not been addressed in detail in the ISO 19906.

In particular, the scope of the guideline is to provide practical guidance on key issues related to the following topics:

- Design methodology, particularly relating to safety philosophy and probabilistic design

- Characteristics, properties, and conditions for sea ice and icebergs in selected areas

- Ice action scenarios and load prediction algorithms for fixed and floating structures

- Discussion of structure response for key design issues

- Case studies for fixed and floating structures.

The JIP participants include Barlindhaug, Daewoo, ENI, Hyundai, Olav Olsen, Keppel, Repsol, SBM, Shell, Statoil, Transocean, and the BOEMRE. The project is anticipated to be completed by 2012.

Conclusions

When thinking about the present status of arctic technology, thought must be given to whether there is sufficient confidence to support oil and gas exploration and production development in arctic regions. As always, this is a balance between risks and benefits for all stakeholders.

The challenges are numerous and significant, but the associated risks are more manageable now than ever. Today’s technology makes it possible to monitor the condition of the arctic facility and its associated systems in real time and remotely control sensitive equipment from shore. Even with the considerable uncertainty associated with ice loading and the design criteria, it is possible to mitigate these issues using probabilistic methods and to incorporate a reliable monitoring system and innovative designs that allow ductile structural behavior and fail-safe arrangement.

Depending on the water depth and the ice conditions, many arctic designs have been proven in the past, and that experience is going to be beneficial in designing new structures for deeper waters and more severe ice conditions.

The recently issued ISO 19906 standard does cover a very wide scope and will be invaluable to the designers and operators of arctic structures. The document still lacks detail for ice load calculations especially for floating systems. Also, the requirement that ice structure interaction should be performed using probabilistic methods is too general and an alternative deterministic method should be defined. However, the designers will be relying on class societies for more specific guidance. DNV is going to produce such guidance in mid-2012 after work is completed on the JIP ICESTRUCT.

The definition of local ice pressure dependence on the contact area has been improved in the new ISO standard. However, due to the sensitivity of the structural weight to the local pressure and hence the feasibility of the design, it is important to optimize the design by employing plastic and nonlinear design methods.

The experience from existing arctic shipping, exploration, and production has been successful to date. There is no doubt that existing technology can produce year-round drilling and production systems in all the contemplated arctic regions efficiently, with the same or better reliability than currently experienced in field developments in deepwater and harsh environments.

Acknowledgment

Based on a paper presented at the Deep Offshore Technology International Conference and Exhibition held in Amsterdam, Nov. 30 through Dec. 2, 2010.

References

American Petroleum Institute, “Recommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms,” API RP 2A, 1st through 21st Editions, 1969-2005.

American Petroleum Institute, “Recommended Practice for Planning, Designing and Constructing Structures and Pipelines for Arctic Conditions,” API RP 2N, 2nd Edition, December 1, 1995.

Brinkmann, C. and Davenport, G, “Mobile Year-Round Arctic Drilling System,” Pub. No. US 2010/0221069 A1, September 2, 2010.

Cammaert, A.B. and Horn, A.M. “New DNV Recommended Practice for Ice Effects on Arctic Offshore Structures,” POAC09-50, Lulea, Sweden.

Canadian Standards Association (CSA), “Design, Construction and Installation of Fixed Offshore Structures – General requirements, design criteria, the environment, and loads”, CAN/CSA-S471-04, February 2004.

Det Norske Veritas (DNV), ICESTRUCT JIP, “Ice Effects on Arctic Offshore Structures,” October 1st, 2009.

Det Norske Veritas (DNV), Rules for Classification of Ships, PART 5 CHAPTER 1, “Ships for Navigation in Ice,” July 2010.

DNV Offshore Standard OS-C201, “Structural Design of Offshore Units (WSD Method),” October 2008.

DNV Offshore Standard OS-C101, “Design of Offshore Steel Structures General (LRFD Method)”, October 2008.

DNV Recommended Practice RP-A203 “Qualification Procedures for New Technology,” September 2001.

Gautier, D.L., Bird, K.J., Charpentier, R.R., Grantz, Arthur, Houseknecht, D.H., Klett, T.R., Moore, T.E., Pitman, J. K., Schenk, C.J., Schuenemeyer, J.H., Sørensen, Kai, Tennyson, M.E., Valin, Z.C., and Wandrey, C.J. 2009, “Assessment of Undiscovered Oil and Gas in the Arctic,” Science v. 324, p.1175-1179.

Ghoneim, G. A., “Recent Developments in Offshore Codes, Rules and Regulations for Deepwater and Arctic E&P Systems,” ISOPE-CCC-01, Vancouver, Canada, July 6-10, 2008.

Ghoneim, G. A., and Por-Feng Peng, “Application of Recent Ice Class Requirements for Arctic E&P Offshore Structures,” ISOPE-CC-01, Osaka, Japan, June 21-26, 2009.

Ghoneim, G. A., Cammaert, A. B. (Gus), and Morten Mejlænder-Larsen “Arctic Challenges – A Treatise of Past and Recent Developments,” ICETECH10-183-USA, Anchorage, AK, September 20-23, 2010.

Gunningham, M., Varley, C., and Cagienard, P., “The Integrated Use of New Technology in the Development of the Sakhalin II Project,” SPE 114805, Moscow, Russia, 28-30 October, 2008.

IMV Projects Atlantic, “Arctic Offshore Technology Assessment of Exploration and Production Options for Cold Regions of the US Outer Continental Shelf,” United States Department of the Interior Minerals Management Service, Technical Report No. TR-001, January 31, 2008.

International Standards Organization, ISO/FDIS 19901-1:2005(E) “Metocean design and operating considerations,” voting terminated 2005-09-28.

International Standards Organization, ISO/FDIS 19906 “Arctic Offshore Structures,” ISO TC 67/SC 7, 2010.

Murray, J. J. and Yang, C. K., “A Comparison of Spar and Single Column Floater in an Arctic Environment,” OTC 19797, 4-7 May, 2009.

Sablok, A. and S. Barras, “The Internationalization of the Spar Platform,” OTC 20234, 4-7 May, 2009.

U.S. Geological Survey, Circum-Arctic Resource Appraisal (north of the Arctic Circle) Assessment Units GIS Data, 2009.

U.S. Geological Survey, “U. S. Geological Survey Oil and Gas Resources Assessment of the Russian Arctic”, DOE Award No. DE-A126-05NT15538, Final Report submitted to the Department of Energy National Energy Technology Laboratory, July 2010.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com