World’s largest spar platform opens deepwater production offshore mid-Norway

Aasta Hansteen could serve as hub for stranded gas fields

Jeremy Beckman, Editor, Europe

Aasta Hansteen,which came onstream late last year is Norway’s deepest offshore development to date, in nearly 1,300 m (4,265 ft) of water. The location, 186 km (115 mi offshore) in the northern Norwegian Sea, and 120 km (75 mi) northwest of the Norne FPSO, is one of the harshest for any Norwegian project to date in terms of waves and weather; during the pre-sanction design phase, the area was also remote from offshore export infrastructure. And there was uncertainty over the long-term production potential of gas/light oil reserves in the area.

For these and other reasons Equinor (then Statoil) and its partners in license PL 218 opted for Norway’s first single point anchor reservoir (spar) production platform, with subsea completions, and produced gas directed through a new offshore pipeline north of the Arctic Circle to the existing reception terminal at Nyhmana in mid-Norway. This would also be the world’s largest spar platform to date, and the first with onboard storage for produced condensates. Norway’s parliament sanctioned the development in 2013.

The newly onstream Aasta Hansteen spar platform. (Courtesy Equinor/Roar Lindefjeld and Bo B. Randulff)

Field history

The initial development comprised three fields. In 1997, BP discovered Luva, since renamed Aasta Hansteen after the Norwegian women’s rights campaigner. Nine years later, Equinor became operator of the license by acquiring BP’s 25% interest and went on to drill the Snefrid South and Hakland discoveries. In 2015, the company also proved gas in three satellite prospects, of which Snefrid North – 6 km (3.7 mi) west of Hansteen – was included as a late addition to the development and which is due to come onstream in late 2019. Estimated recoverable volumes for the four fields are around 55.6 bcm of gas and 600 MMcm of condensate.

A year prior to partner sanction, Technip (now TechnipFMC) won a front-end engineering and design (FEED) competition for the spar platform: Equinor had also evaluated a circular Sevan FPSO but concluded that a spar would be superior in terms of minimizing motions and that this would in turn reduce fatigue on the risers. It subsequently awarded TechnipFMC the engineering, procurement, construction and transportation contract, in partnership with Hyundai Heavy Industries in Ulsan, South Korea, for the 200-m (656-ft) tall, 50-m (164-ft) diameter, 46,000-metric ton (50,706-ton) hull. In addition, the contract covered the mooring system and design of the steel catenary risers, which were a first for Norway, and which were selected partly as a lower-cost alternative to flexible risers.

TheSeven Arctic loading suction anchors and templates produced by Aker Solutions in Sandnessjøen for Aasta Hansteen and Snefrid Nord. (Courtesy Aker Solutions)

Equinor exclusively assigned Hyundai the EPC contract for the 21,000-t topsides comprising a conventional integrated deck, living quarters and a flare, with gas production capacity of 23 MMcm/d, and storage for up to 25,000 cu m (883,000 cu ft) of condensate for subsequent offloading to shuttle tankers. CB&I (since merged with McDermott) undertook the topsides FEED and detailed engineering, the solution involving use of heating and separation for conventional gas dehydration; dew point control; compression of the gas for export through the pipeline to Nyhamna; and stabilization of the condensate.

Hyundai subcontracted Dutch fabricator CKT projects in Rotterdam to build the eight-story, 2,600-t, 108-bed living quarters, designed to withstand extreme weather conditions, and which would later be transported to Ulsan by theDockwise Vanguard vessel; and Kvaerner to manage and assist completion of the platform. Among the other main topsides items, GE would supply the gas turbines under a five-year frame agreement with Equinor, with Unasys responsible for mechanical completion and commissioning services.

Subsea systems

Aasta Hansteen’s production will come from eight wells, with the semisubTransocean Spitsbergen making good progress on the campaign, according to a recent update by the Norwegian Petroleum Directorate (NPD). Equinor awarded Aker Solutions the NOK2-billion ($234-million) EPC contract for the subsea production system (SPS) in early 2013 following a FEED competition with FMC. Aker Solutions’ manufacturing plant in Tranby, Norway, has delivered horizontal Xmas trees for the wells, comprising four for Luva, two for Hakland, one for Snefrid Sør, and one spare. The package included 8-in. wet gas flow meters for the design production rates, due to the fact that the multiphase meter is unusually large.

In addition, the SPS contract covered supply of two four-slot and one single-slot subsea templates, all built at Aker Solutions’ plant in Sandnessjøen and installed by EMAS AMC’sBoa C construction vessel at the seafloor locations in mid-2015. The template structures weigh from 115-180 metric tons (127-198 tons) and the suction anchors from 100-115 metric tons (110-127 tons), explained Severin Lindseth, project manager at the time for Aker Solutions. “The templates are each supported by only one suction anchor and there are systems that facilitate separate installation of the suction anchor and the template structure. The templates also allow for guideline-less installation of the trees.” Momek manufactured the suction anchors for the templates and for the platform’s mooring lines and SCRs. Under a separate contract, awarded following another design competition, Aker Solutions’ plant in Moss, Norway manufactured one dynamic and three static umbilicals ranging in length from 4 to 7 km (2.5 to 4.3 mi).

Lowering of one subsea template into water at installation. (Courtesy Aker Solutions)

Earlier this year, Equinor cited Aasta Hansteen as one of its ongoing projects where costs had come down due to collaborative efforts with the well equipment providers. One of Aker Solutions’ contributions in this regard, Lindseth said, was the provision of an advanced deepwater Open Water workover system.

Subsea 7 won the NOK2.2-billion ($257-million) EPIC contract that covered supply and installation of 18 km (11.2 mi) of infield flowlines, all featuring BuBi mechanically-lined pipe; installation of the umbilicals and tie-ins of these and the flowlines; and installation of the four-off SCRs and associated SCR/flowline anchors. The subsea network comprises two production flowlines from the Luva template to the platform; single production flowlines from both the Hakland and Snefrid Sør templates to the platform; three SCRs for the flowlines, and one export SCR to the export pipeline system.

In addition, Subsea 7 was responsible for the rigid spools, manufactured at its Vigra spoolbase, which would connect the flowlines to the manifolds; and for transportation of the spar to the field location following pre-commissioning at Kvaerner Stord, and subsequent hookup of the mooring lines to the platform and SCR/umbilical pull-in/hang-off operations. For these combined programs the company deployed a total of six vessels, theSeven Oceans, Seven Viking, Havila Subsea, Normand Oceanic, Skandi Acergy, and Skandi Skansen. Among the contractors assisting these various campaigns, Nautronix was commissioned to supply a subsea positioning system for the installations, and Van Oord the rock dumping to stabilize both the templates and the infield lines.

Aasta Hansteen substructure upending. (Courtesy Equinor/Espen Rønnevik/ Roar Lindefjeld)

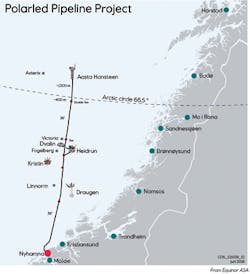

Polarled

During planning for Aasta Hansteen, the partners were aware that capacity through the Åsgard Transport System – the sole established gas export trunkline in the Norwegian Sea – would be operating at full capacity for a few more years. With other stranded gas discoveries in the area, there was general recognition of the need for a second major pipeline system. Norwegian trunklines operator Gassco started the planning process, with Equinor taking over in late 2011. Following a final investment decision, Equinor submitted a plan for installation and operation of the Polarled pipeline in January 2013 which Norway’s parliament approved five months later.

Danish contractor Ramboll performed detailed design of the 482-km (300-mi), 36-in., 70-MMcm/d capacity pipeline, which the company claimed would be the world’s deepest water installation to date for a line of this diameter. Equinor also contracted the Marubeni Itichu/JFE consortium to supply 325,000 t of linepipe, coated externally and internally by Indonesia’s Wasco and subsequently shipped to a newly built base in mid-Norway for the application of concrete coating. Kongsberg manufactured associated subsea structures including in-line tees and connection systems – six tie-in points were pre-installed to accommodate gas from other future Norwegian Sea field developments.

Between March and September 2015, Allseas’Solitaire laid the entire pipeline from the field location to the terminal at Nyhamna receiving gas from the Ormen Lange field, and which would undergo expansion for Aasta Hansteen under operator Shell’s management. On completion of the pipeline installation, Equinor said expenditure on the system ended up NOK4.5 billion ($526 million) below budget at NOK6.5 billion ($760 million) as a result of various measures that allowed it to adjust the capacity and price to the market’s needs. Aasta Hansteen’s gas will join Ormen Lange’s in heading through the Langeled pipeline to England via the Sleipner field hub in the North Sea, with further export options from Sleipner through the existing transportation network delivering Norwegian gas to continental Europe.

Spar platform tow from Stord to the field. (Courtesy Woldcam/Equinor)

Platform tow

Construction of the platform in Ulsan took 39 months to complete, and shipment to Norway followed in two stages. In April 2017, the cylindrical substructure was loaded onto the heavy transport vesselDockwise Vanguard which proceeded to sail west via the Cape of Good Hope, arriving 60 days later at Hoylandsbig in the county of Sunnhordland where the hull was floated off the vessel and towed to the Klosterfjorden outside the island of Stord, near Bergen. There it was upended from the vessel into a vertical position and made ready for the mating with the integrated deck, which arrived onboard the Dockwise White Marlin at the end of November 2017 following float-off and towing from Ølensvåg. Mating took around three days to complete, with the assistance of various tugs, barges and an onsite team of 150 personnel managing and verifying alignments, measurements and ballasting.

In April 2018, the 339-m (1,112-ft) tall, 70,000-metric ton (77,162-ton) platform underwent an 11-day tow by five tugs to the field location. At the shallowest point en route the clearance beneath the keel was 14 m (46 ft), and 20 m (65.6 ft) up to the crossing over the high-voltage cable over Langenuen. On arrival it was connected to the pre-installed polyester mooring lines, manufactured by Lankhorst, with First Subsea supplying the mooring connectors. Kvaerner then began assisting Equinor with offshore hookup and preparations for the start of production.

ABB is responsible for the platform’s electrical, control and telecommunication system, from delivery through commissioning, automation of the plant start-up sequences and related services. Following start-up, the company will also provide support as required to the platform and to Equinor’s Operations North organization in Harstad, which will supervise offshore activity. ABB Oil, Gas and Chemicals in Norway managed design and engineering, with Equinor requesting various features to improve the ease of operating the plant during normal operation and to automate the start-up sequences.

ABB Ability 800xA simulator saved an estimated 40 days in the commissioning phase by reducing manual interventions by 98%. (Courtesy ABB)

One of ABB’s tasks was to make the process leading up to first gas as efficient and fast as possible, reducing a sequence of over 1,000 conventional manual interventions to the bare minimum. For this the company applied ABB Ability, which it describes as “a unified, cross-industry digital offering, extending from device to edge to cloud, with devices systems, solutions, services and a platform that allow clients to know and do more, better and together.”

The company deployed its ABB Ability System 800XA simulator in the Professional version which allows the Equinor team to operate and improve operations “in a pure virtual environment.” The simulator’s control system is disconnected from the physical process and is instead simulated by a high-accuracy mathematical dynamic process model that represents the physical process of the plant. The model, integrated with the simulator, is said to provide a realistic simulation environment.

According to ABB Oil, Gas and Chemicals Managing Director Per Erik Holsten, by automating much of the process the number of manual interventions was limited to 20. The simulator is also said to have saved around 40 days in the commissioning phase through identifying and improving 57 different aspects of the start-up process, and this led to a corresponding reduction in trouble-shooting and corrective measures, ABB claimed, of around 2,700 man-hours. Obstacles that came to light included inter-dependencies between the physical instrumentation and control logic that would be difficult or time-consuming to operate.

In addition, ABB provided a condition monitoring system that can monitor over 100,000 maintenance conditions for more than 4,000 equipment items, along with tools for alarm management and alarm rationalization, and third-party system integration of essential data traffic.

Conclusion

The NPD estimates investment costs for the entire development at around NOK37.5 billion ($4.38 billion), in line with the scenarios forecast in the development plan. At peak, expected shortly after start-up, Aasta Hansteen will deliver 23 MMcm/d with the plateau figure set to be sustained until 2023, including output from Snefrid Nord. Tie-in points have been installed at the platform to accommodate future developments in the area after the field has come off plateau: these could include new discoveries drilled by Equinor close to Aasta Hansteen, and the company’s 16-bcm Asterix field, 80 km (49.7 mi) west of Aasta Hansteen, drilled in 2009 in 1,360 m (4,462 ft) water depth. •