ABB tasked with automation at North Sea Krafla platform

Offshore staff

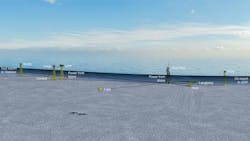

ZURICH, Switzerland – Equinor has contracted ABB to implement its Adaptive Execution methodology at the unmanned processing platform (UPP) planned for the Krafla field in the Norwegian North Sea.

Adaptive Execution is said to integrate expert teams, new technologies, agile processes, shared learnings and proven methodologies, linked to the digital ABB Ability platform.

In addition, ABB will provide automation solutions for the Krafla oil and gas field development, covering the Krafla, Fulla, and North of Alvheim licenses.

The UPP will be remotely controlled from an onshore control center using the distributed control system ABB Ability System 800xA equipped with Select I/O. In addition, the ABB system will monitor and control two unmanned wellhead platforms and a subsea production system.

The company will develop a digital twin to simulate, test, and verify functions needed for unmanned operations on the control system, prior to installation.

Brandon Spencer, president of ABB Energy Industries, said: “The platform has been designed with the intention of having no people on board, with no helipad, and the only possible access via ship.

“Instead, a new generation of remotely based operators will sit onshore, with the ability to start operations at the touch of a button. It is critical, therefore that collectively we get the design right the first time around. Everything needs to be tested and verified before being installed offshore.

Through the Adaptive Execution methodology, the company expects to streamline the full project execution, combining modular design with standardized, repeatable processes.

Johan de Villiers, Oil and Gas lead for ABB Energy Industries, said: “With digitalization and virtualization at [Adaptive Execution’s] core we can unlock significant project value for Equinor in this project, not least by designing and testing everything in a virtual environment, eliminating design failures early on.

“As a result, we can reduce delivery schedules by up to 30%, minimize the number of engineering hours spent on project testing, installation, and commissioning by 85%, and lower automation related setup costs lowered by up to 40%.”

The new platform’s power needs will be supplied from Norway’s onshore grid to reduce local emissions.

04/28/2021