P.3 ~ Industry unveils new products and technologies at OTC 2014

View Article as Single page

FMC Technologies received the award for the offshore footless loading arm (OLAF). The technology was developed for LNG transfer between an FLNG vessel and a conventional LNG carrier, in side-by-side moored arrangement in offshore conditions.

The OLAF design is able to accommodate the large elevation difference between an FLNG deck, where it is installed, and an LNG carrier piping connection at lower level, without overloads. The company says the system covers 100% of side-by-side operability in harsh environmental conditions, thanks to its concept, its targeting system for connection assistance, and constant position monitoring system, SIL3, to manage the emergency disconnection.

GE Oil & Gas received two spotlight awards. The first was for the Zenith GFI ground fault immune ESP monitoring system. The system offers a solution that cannot be disturbed by ground faults, enabling operators to maintain well surveillance for production optimization and pump protection, despite fault conditions.

The company's second award was for the SeaLytics, a software solution that enables drilling contractors to monitor performance and plan maintenance of BOPs using predictive analytics based on actual component performance data. The software can improve BOP system uptime, reduce unnecessary maintenance, and lead to better cost forecasting.

Geoservices, a Schlumberger company, was recognized for the fluid loss and gain detection service (FLAG). The service provides accurate fluids monitoring and precise coriolis flow metering with any drilling fluid on any rig, and in operating conditions including drilling, tripping, circulating, and cementing.

Halliburton Drill Bits and Services won for the TDReam tool. Challenged to design a tool to increase efficiency, Halliburton developed a solution that has the added benefits of optimized steerability and fluid flow, and reduced tool length based on the proven reliability of the NBR reamer technology.

SBM Offshore was recognized for the very high pressure fluid swivel. This new technology increases the operating range of high-pressure swivels by using a patented technique to cascade the pressure drop over multiple seals. The 12-in. prototype toroidal swivel has been fully qualified to 830 barg (12,000 psig), including long-term endurance test runs, and has the potential to operate at more than 1,000 barg (14,500 psig).

The company says this swivel is specifically aimed at gas or water injection from FPSOs into ultra-high pressure reservoirs, such as the Lower Tertiary fields of the US Gulf of Mexico.

Schlumberger received the award for the Seismic Guided Drilling service, which predicts formation pressures hundreds of meters ahead of the bit while drilling. The service uses both surface seismic and logging-while-drilling (LWD) data to provide a 3D look-ahead velocity model with reduced uncertainty. The company says this model leads to better geological and geomechanical description enabling proactive drilling decisions, particularly in deepwater exploration.

Velocities ahead of the bit are re-calculated from seismic reflections by using LWD velocities behind the bit as a constraint. Compared with pre-drill predictions, this provides much more accurate results, which can be used in velocity-to-pressure transforms to give more reliable formation pressures.

Weatherford was recognized for the CasingLink EM antenna system. The technology was developed to address the signal attenuation encountered while drilling in deeper depths with an EM telemetry system. This method employs an insulated wire that is externally attached to a standard casing string; a borehole receiver typically located downhole and connected to the casing; and a surface transceiver.

The borehole receiver picks up the EM signal at the casing connection terminal and transmits it via the external signal wire to the surface transceiver, which decodes the EM signal. The wire exits the casing near the surface and passes through a wellhead modified to accept the cable pass through. There is negligible signal attenuation within the transmission wire, which increases telemetry depth.

West Production Technology AS won the award for SwarfPak, a technology for P&A and slot recovery with reduced rig time and reduced environmental footprint. The company says the most revolutionary characteristic of the technology is that all the swarf particles will be deposited and left downhole, avoiding the use of surface swarf handling equipment. Another benefit is that the milling speed is increased.

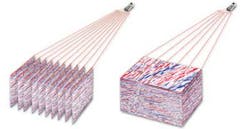

WesternGeco was recognized for the IsoMetrix marine isometric seismic technology, which enables the first truly 3D measurement of seismic wavefields using towed streamers. A new streamer design that includes measurement of the vertical and crossline gradient of the seismic wavefield enables unaliased reconstruction of the pressure wavefield between the streamers.

The company says the resulting fine isometric sampling in both crossline and inline directions provides the most accurate images of the subsurface ever recorded, making the data suitable for many interpretation and reservoir modeling applications in exploration and reservoir development.

OTC returns to Houston at NRG Park May 4-7, 2015.