P.2 ~ DeepStar study assesses cost-effective dry tree solutions

View Article as Single page

Development themes

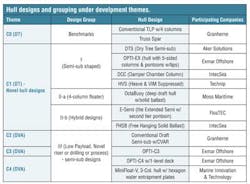

The five development themes evaluated with DT or DVA capability are illustrated in on page 73.

Theme C0 with benchmark hull. Conventional development using 4-column TLP or truss spar with dry trees and TTRs with tensioners for drilling and production and SCRs for water injection (WI) and export. TLP requires hydro-pneumatic tensioners (pull or push type) with low stroke while truss spar requires RAM tensioners with long stroke. DVA to wells is obtained through TTRs. Conventional TLP hull with 4-column design and 2 level deck enables quay-side integration and pre-commissioning of topsides, whereas truss spar design with slender hull and 3 level deck requires longer duration offshore integration and commissioning of topsides by use of HLV and other vessels.

Theme C1 with novel hull. This development theme considers a novel semisub shaped hull (as shown) or its hybrid design variation to support dry trees and TTRs with RAM tensioners for drilling and production, and SCRs for WI and export. DVA of wells is obtained through TTRs. The 4-column novel hull designs are sized to obtain low heave motions that enable use of standard RAM tensioners and reduced compression at SCR sections near seabed. Cost reduction and reduced schedule is achieved using 'off-the-shelf' components.

Theme C2 with novel riser.This development theme requires a conventional to medium draft 4-column semisub with compliant vertical access risers (CVARs) for production and SCRs for WI and export. A workover rig is required on the platform for DVA of individual wells through CVARs. The wells with wet trees are at a suitable distance from the production platform for drilling and completion operations by MODU and SIMOPS can be undertaken. The hull draft is governed by low heave velocity and acceleration design constraints at SCR porches at pontoons. Significant size and cost reductions are obtained due to the elimination of tensioners while still preserving DVA benefits.

Theme C3 with novel drilling. This development theme considers a drilling rig and a drilling TTR with RAM tensioner supported at deck of a medium draft semisub hull. This is a wet tree solution and DVA to wells is obtained through the drilling riser. Two additional SCRs as production risers connect the platform to a subsea manifold, which is located at distance from the wells. SCRs are required for WI and export as done in C1 and C2. The tensioner stroke for drilling TTR could be higher than for the production TTRs and with no production TTR the payload and hull size are reduced.

Theme C4 with novel processing. This development theme evaluates the potential benefits of further reduction in payload on hull and mooring sizing from placement of processing units at seabed. The drilling and subsea support operations are undertaken from the platform deck, thus a drilling rig, drilling TTR with long stroke RAM tensioner, and control umbilicals are required. DVA to wells is obtained through the drilling riser. Two options are shown for C4 theme, with WI unit either at the platform deck or at the seabed. Additional power generation is required at deck for subsea separation, boosting, and water injection units. The topsides and risers payload on hull are reduced, and due to reduction of production risers (TTRs or SCRs) and SCRs, design constraints on hull are reduced and low draft minimal size hull designs are considered. The minimal hull is designed to enable quayside integration and commissioning of topsides at reduced cost.

The study focused on evaluation of the above development themes for three regions (Gulf of Mexico, West of Africa, and offshore Western Australia -- GoM, WoA, and OWA) and three water depths (3,000 ft, 6,000 ft, and 8,000 ft), i.e., a total of nine design cases for DVA themes for benchmark cases and various novel hull and riser concepts. Electric submersible pump (ESP) deployment is considered in all oil production wells in GoM and WoA cases for increased productivity.

Due to focus of this project on evaluation of low-cost solutions for marginal fields, the reservoir depths that are feasible to drill by a modular rig were considered.

Design basis and constraints

A detailed design basis document was developed to provide a common basis for all hull and riser designs evaluated under five DVA themes. The details of topsides estimates and layouts, riser sizes and loads, umbilical loads, and basis for execution plans and cost estimates were provided to concept owners to obtain estimates of hull and mooring systems for different designs.

The modular drilling rig is considered in this project for drilling and workover operations. The deck area required for this rig is 12,525 sq ft and its weight in different conditions are: dry 2,000 st; operating 3,850 st (with 500 st hook load); and survival 3,350 st. The well bay is assumed as 60 ft x 60 ft.

Dual casing TTR designs were considered for drilling (19.75 in. outer casing) and production (13.813 in. outer casing) risers for all three regions. The SCR estimates for WI riser were generated for 10.75 in. OD for GoM and WoA regions and for export risers for 18 in. OD for all three regions.

The payloads on hull from topsides with modular drilling rig, risers and umbilicals in 8,000 ft water depth design cases varied from 20,500 st for C0 and C1, 18,200 st for C2, 16,500 st for C3, 12,000 st for C4-a, to 10,500 st for C4-b. The corresponding payloads on hull in 3,000 ft water depth design cases were 24% less for C0 to C2, 14% less for C3, and up to 7% less for C4.

The novel designs have introduced unique features to obtain low heave motions to enable SCR design and TTR design with standard tensioner stroke. Thus, the global response constraints on hull sizing and design to enable design of risers were considered for safety categories B and S. Safety Category B represents the design level, and safety category S represents the survival level criteria.

The GoM-6000 (with upper bound metocean criteria applicable to Central metocean zone) and WoA-6000 were identified as the minimum number of evaluation cases for all 13 designs.