DeepStar study assesses cost-effective dry tree solutions

R. Aggarwal

D. Barton

Granherne, a KBR Company

R. Seah

Chevron

G. Kusinski

DeepStar/Chevron

The development of deepwater fields (< 5,000 ft) in the Gulf of Mexico (GoM) with dry tree (DT) and direct vertical access (DVA) operations have been mostly performed using TLPs and spars. Ultra-deepwater fields (> 5,000 ft) have been developed with spars.

Due to a significant increase in tendon cost with water depth, the use of TLP design, with advantages from low tensioner stroke and quay-side integration of topsides, has remained in the 3,000 ft to 5,200 ft range. The spar design requires long stroke RAM style tensioners and offshore integration of topsides by heavy-lift vessel (HLV). The current qualified limit of top tension riser (TTR) tensioner stroke is 28 ft (design level) for the spar design, and it requires larger hull and mooring sizes to keep the riser tensioner stroke within this limit.

The alternative semisub shaped hull has been used as a production platform in the GoM with tieback of subsea wells at distance. These wells are drilled by a mobile offshore drilling unit (MODU), and tied to the semisub by flexible risers in lesser water depths and by steel catenary risers (SCRs) or steel lazy wave risers (SLWRs) in deeper water depths. One large semisub, theThunder Horse platform, also includes a drilling rig.

The feasibility of platforms in GoM has been further impacted by significant increase in the metocean criteria after Katrina and other hurricanes. The platforms designed to post-2005 (post-Katrina) specifications would require higher deck elevations, greater topsides payload, longer tensioner stroke, more robust station-keeping systems, and larger hull displacements.

The new metocean criteria also led to the division of GoM into three zones (central, transition, western) with varying metocean design data. The new maximum wave height is about 30% higher for the Central GoM and 13% higher for the Western GoM than the pre-2005 criteria. The impact on designs and estimates of TLP, spar, and semisub from new criteria varies. The impact on semisub designs is generally less than on the TLP and spar designs.

The DT or DVA capability is sought to reduce the associated opex when a MODU is mobilized to perform operations such as ESP replacement. The DT capability is obtained with the drilling rig supported on the floating production platform. Alternatively, pre-drilling is performed from a MODU and the floating production platform supports a workover rig in the case of wells below the platform. In the case of subsea wells at distance from the platform, a MODU is required for workover operations. These approaches have provided economic solutions for the development of large fields. In the case of deepwater marginal fields at remote locations with low field life and lower number of production risers, it is desirable that drilling, production, and export functions are undertaken from a single floating platform. Thus lower cost hull and mooring system designs are required for economic viability, which could be obtained by use of semisub hull designs with polyester mooring system. In general, the semisub hull-shaped designs require long stroke RAM tensioners as with a spar platform.

A large number of semisub or hybrid shape hull designs with dry tree capability have recently been developed by various concept owners. These have been evaluated for specific field applications with unique requirements and drivers, or are in various technology development stages. Some of these have been evaluated as dry tree solutions for development of large fields with 12 production risers and a large drilling rig for deeper reservoirs. For two novel hull designs, efforts have been undertaken in RPSEA-funded projects to increase their technology readiness levels (TRL).

The feasibility of several of these novel solutions to provide an economic solution for development of deepwater marginal fields is unknown. Their technical performance in multiple regions and water depths, scalability, constructability, and associated economic factors are important to determine their competitive advantage against proven TLP and spar designs. The evaluation of new designs as enabling solutions, beyond the feasibility of TLP and spar, is required for a combination of water depths, regional parameters, and payloads.

Thus DeepStar funded this project to evaluate a large number of novel concepts for a common design basis, focusing on identification and characterization of key technical performance parameters, constructability, and economic factors. The economic factors are most important for these designs to be considered attractive for development of marginal fields with short field life and fewer wells.

The goal here is to present the alternative development themes for obtaining dry tree and direct vertical access capability, key design basis and design constraints, alternative hull and riser designs considered in various groups for comparative assessment, and important variations among design groups.

Development themes

The five development themes evaluated with DT or DVA capability are illustrated in on page 73.

Theme C0 with benchmark hull. Conventional development using 4-column TLP or truss spar with dry trees and TTRs with tensioners for drilling and production and SCRs for water injection (WI) and export. TLP requires hydro-pneumatic tensioners (pull or push type) with low stroke while truss spar requires RAM tensioners with long stroke. DVA to wells is obtained through TTRs. Conventional TLP hull with 4-column design and 2 level deck enables quay-side integration and pre-commissioning of topsides, whereas truss spar design with slender hull and 3 level deck requires longer duration offshore integration and commissioning of topsides by use of HLV and other vessels.

Theme C1 with novel hull. This development theme considers a novel semisub shaped hull (as shown) or its hybrid design variation to support dry trees and TTRs with RAM tensioners for drilling and production, and SCRs for WI and export. DVA of wells is obtained through TTRs. The 4-column novel hull designs are sized to obtain low heave motions that enable use of standard RAM tensioners and reduced compression at SCR sections near seabed. Cost reduction and reduced schedule is achieved using 'off-the-shelf' components.

Theme C2 with novel riser.This development theme requires a conventional to medium draft 4-column semisub with compliant vertical access risers (CVARs) for production and SCRs for WI and export. A workover rig is required on the platform for DVA of individual wells through CVARs. The wells with wet trees are at a suitable distance from the production platform for drilling and completion operations by MODU and SIMOPS can be undertaken. The hull draft is governed by low heave velocity and acceleration design constraints at SCR porches at pontoons. Significant size and cost reductions are obtained due to the elimination of tensioners while still preserving DVA benefits.

Theme C3 with novel drilling. This development theme considers a drilling rig and a drilling TTR with RAM tensioner supported at deck of a medium draft semisub hull. This is a wet tree solution and DVA to wells is obtained through the drilling riser. Two additional SCRs as production risers connect the platform to a subsea manifold, which is located at distance from the wells. SCRs are required for WI and export as done in C1 and C2. The tensioner stroke for drilling TTR could be higher than for the production TTRs and with no production TTR the payload and hull size are reduced.

Theme C4 with novel processing. This development theme evaluates the potential benefits of further reduction in payload on hull and mooring sizing from placement of processing units at seabed. The drilling and subsea support operations are undertaken from the platform deck, thus a drilling rig, drilling TTR with long stroke RAM tensioner, and control umbilicals are required. DVA to wells is obtained through the drilling riser. Two options are shown for C4 theme, with WI unit either at the platform deck or at the seabed. Additional power generation is required at deck for subsea separation, boosting, and water injection units. The topsides and risers payload on hull are reduced, and due to reduction of production risers (TTRs or SCRs) and SCRs, design constraints on hull are reduced and low draft minimal size hull designs are considered. The minimal hull is designed to enable quayside integration and commissioning of topsides at reduced cost.

The study focused on evaluation of the above development themes for three regions (Gulf of Mexico, West of Africa, and offshore Western Australia -- GoM, WoA, and OWA) and three water depths (3,000 ft, 6,000 ft, and 8,000 ft), i.e., a total of nine design cases for DVA themes for benchmark cases and various novel hull and riser concepts. Electric submersible pump (ESP) deployment is considered in all oil production wells in GoM and WoA cases for increased productivity.

Due to focus of this project on evaluation of low-cost solutions for marginal fields, the reservoir depths that are feasible to drill by a modular rig were considered.

Design basis and constraints

A detailed design basis document was developed to provide a common basis for all hull and riser designs evaluated under five DVA themes. The details of topsides estimates and layouts, riser sizes and loads, umbilical loads, and basis for execution plans and cost estimates were provided to concept owners to obtain estimates of hull and mooring systems for different designs.

The modular drilling rig is considered in this project for drilling and workover operations. The deck area required for this rig is 12,525 sq ft and its weight in different conditions are: dry 2,000 st; operating 3,850 st (with 500 st hook load); and survival 3,350 st. The well bay is assumed as 60 ft x 60 ft.

Dual casing TTR designs were considered for drilling (19.75 in. outer casing) and production (13.813 in. outer casing) risers for all three regions. The SCR estimates for WI riser were generated for 10.75 in. OD for GoM and WoA regions and for export risers for 18 in. OD for all three regions.

The payloads on hull from topsides with modular drilling rig, risers and umbilicals in 8,000 ft water depth design cases varied from 20,500 st for C0 and C1, 18,200 st for C2, 16,500 st for C3, 12,000 st for C4-a, to 10,500 st for C4-b. The corresponding payloads on hull in 3,000 ft water depth design cases were 24% less for C0 to C2, 14% less for C3, and up to 7% less for C4.

The novel designs have introduced unique features to obtain low heave motions to enable SCR design and TTR design with standard tensioner stroke. Thus, the global response constraints on hull sizing and design to enable design of risers were considered for safety categories B and S. Safety Category B represents the design level, and safety category S represents the survival level criteria.

The GoM-6000 (with upper bound metocean criteria applicable to Central metocean zone) and WoA-6000 were identified as the minimum number of evaluation cases for all 13 designs.

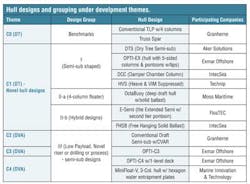

Floating platform alternatives

A total of 11 hull and four riser designs were selected for five development themes with DVA of wells from the platforms. Of these, two were benchmark designs (TLP, truss spar), eight were novel hull designs, one was a conventional semisub design, and one was a novel DVA riser system under various qualification stages and TRLs. One hull was evaluated for three design cases (C1, C3, C4), thus a total of 13 design cases were undertaken. The three other riser designs included proven TTR, SCR, and SLWR.

Eight engineering companies undertook sizing, weight and displacement estimates, global performance analysis, and cost estimation for 13 designs for the common design basis and provided the results for evaluation and comparative assessment in this project.

For comparative assessment, the alternative novel hull and riser systems were considered under three Groups (I, II, and III) as given in the table to enable useful comparison and identify specific (or distinct) design ranges for various parameters for novel designs under each group.

Further details on the key features of these designs can be found in the longer and more detailed paper presented at the recent Deep Offshore Technology conference, and additional references can be found in that document as well.

Technology readiness review

Vortex-induced motion (VIM) susceptibility review was performed for all designs. The unique design features of columns and pontoons in the following novel hulls were identified by concept owners with potential to impact vortices formation and help obtain low-amplitude VIM:

- 5-sided columns in OPTI hull designs (OPTI-DRI-C1, OPTI-C3; OPTI-C4)

- Columns rotated at 120 degrees in case of 3-column MiniFloat-V hull

- HVS design with special measures, such as column steps at pontoon level suppress VIM

- OctaBuoy with unique hull design and closer spacing of columns, which reflect the vortices.

The TRL of the overall designs was addressed in the project by a review of designs of key sub-systems and their development stages. They were allocated TRL from 0 to 7 with "0" for unproven concept and "7" for field proven concept. The following were considered in technology readiness assessment of various sub-systems of each novel design:

- All novel designs in theme C1 require design development and qualification of well bay and deck structure to support up to six RAM tensioners with long strokes and the impact load at bottom out in the robustness criteria. Such work was started and further analysis, design, and testing effort may be required for the designs presented here

- One novel hull design in Group I (OPTI) is in-service in Central GoM with subsea tiebacks

- One design (OctaBuoy) in Group II has been constructed for wet tree application but not installed

- Two novel designs (HVS, E-Semi) have gone through Class approval-in-principle and model tests

- Two novel designs (DCC, FHSB) are in concept development stage and need Class approval-in-principle and model tests in wave basins

- The hull designs for themes C2 (Semi w/CVAR) to C4 (OPTI) require minimum qualification as they have been used with subsea tieback

- The CVAR design uses proven hardware, and requires qualification of larger non-structural ancillary units (buoyancy modules), further analysis and optimization of its configuration and design, and qualification of its installation and operations through the riser

- The MiniFloat-V design concept is in-service for small scale wind energy applications, and requires full design development and qualification of the larger size hull required for oil and gas applications.

Conclusions

The work undertaken in the DeepStar project confirmed the feasibility of semisub shaped and hybrid semisub novel hull designs (theme C1) to provide low-cost DT solutions for the development of deepwater marginal oil and gas fields in three regions. The novel semisubmersible hull designs evaluated in theme C1 overcame the limitations of benchmark TLP and truss spar designs, met all design constraints, and are feasible for quayside or floatover integration of topsides.

The alternative development themes (C2, C3, C4) with wet trees and DVA of wells from the platform were also shown to be feasible with a semisub-shaped hull, but will have increasing cost of subsea units from theme C2 to theme C4. The DVA theme C2 with CVAR, an offset riser, disconnect the drilling and workover operations, and provides opportunity for development of deeper reservoir (>15,000 ft below seabed) without much impact on the platform design. The potential of three-column MiniFloat-V hull design (C4) to support a modular drilling rig, a drilling TTR with RAM tensioners, and SCRs and umbilicals is of high value for cost-effective development of fields in alternative ways and to provide DVA to wells and controls to subsea units.

In 3,000 ft water depth, benchmark TLP designs provide low-cost development solution. In the OWA region, the TLP foundation design would require qualification work; thus a semisub based design with suction anchors could provide a competitive solution. Comparative assessment of these designs showed that the value from novel semisub and hybrid designs increases for ultra-deepwater (> 5,000 ft water depth) and harsh metocean regions such as Central GoM and OWA. In such regions, the novel semisub hull designs would become enabling solutions for development of marginal oil and gas fields.

The alternative hull designs are available with varying TRLs, thus requiring minimum to significant technology qualification efforts. Their use in regions with moderate to benign seastates would require lower tensioner stroke and enable use of some Group I designs. The existing semisub designs in deepwater GoM are proven with wet tree applications and thus would require less qualification effort from addition of DT and DVA operations.

Due to moderate increase in the total payload on hull with water depth for all development themes evaluated, there is a potential for regional standardization of novel hull designs to obtain the "Design-One-Build-Many" capex and reuse benefits. These features would be desirable and enable development of marginal fields with short field life, assumed 10-years in this project, when the semisub based platforms are considered to develop multiple fields. The movement of semisub to another field would be a simpler operation for semisub designs than for a TLP and a truss spar.

The estimates for eight novel hull designs and one novel riser design generated through collaborative industry effort with in-kind participation by eight engineering companies (the concept owners) enabled establishment of a significant database, which is organized in three groups of designs for a useful comparison and assessment. The database provides clarity on impact of regions and water depths on alternative designs, variations among three groups, and comparisons with benchmark TLP and truss spar designs. This database would be valuable for worldwide fields.

Acknowledgments

The authors wish to express their gratitude to DeepStar Management and to their 12 operating companies: Anadarko, BG Group, BP, Chevron, ConocoPhillips, Maersk Oil, Marathon Oil, Nexen, Petrobras, Statoil, TOTAL, Woodside. In addition technical support was provided by the DeepStar X400 Floating Systems technical committee throughout the project and in support of this publication. The authors wish to thank the eight participating concept owners: Aker Solutions, Exmar Offshore, FloaTEC, Granherne, INTECSEA, Marine Innovations & Technology, Moss Maritime, and Technip, for performing in-kind evaluations of their novel concepts for the common design basis and providing detailed reports and comparative assessment metrics. The first two authors also wish to thank Granherne project team at Houston and Perth for the work done for the design basis, benchmark theme C0 and theme C2 design cases. This article is based on a paper presented at the Deep Offshore Technology International Conference & Exhibition held in Aberdeen, Scotland, October 14-16, 2014. The full report with supplementary appendices (about ~2,000 pages) is available to the DeepStar operating companies atDeepStar.org.