New technologies address common challenges in energy sector

Optical system enhances underwater imaging

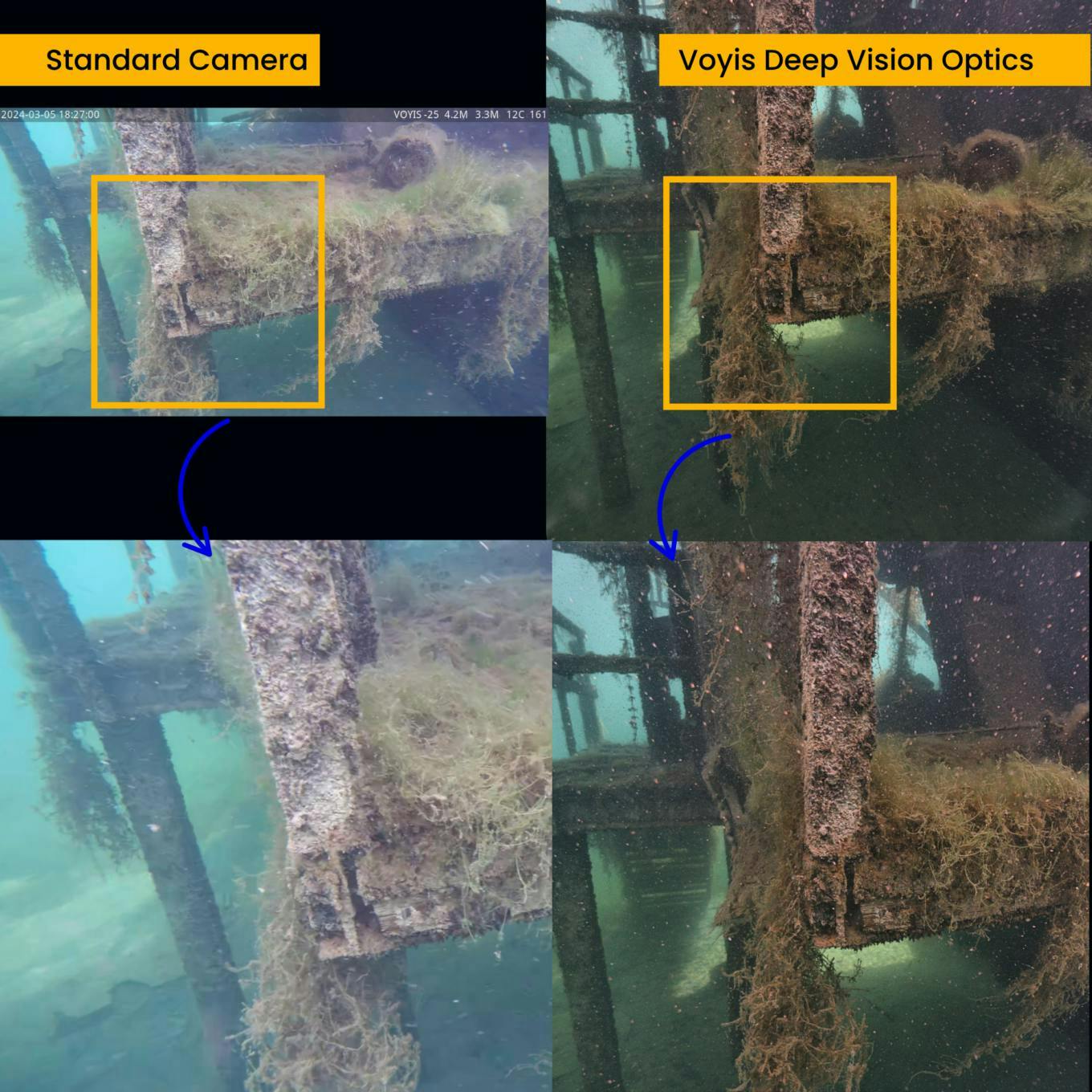

Voyis has released the Deep Vision Optics system, which is designed to enhance image clarity and sharpness in subsea environments. This technology is being released for the Voyis’ Discovery Vision Systems and the Observer Imaging Systems.

The company explained that underwater cameras face a significant challenge in maintaining focus across their entire field of view and working range due to the water medium. Traditional dome viewports affect image formation and focus, leading to poor corner focus that limit the usability of the camera’s field of view. They also reduce the depth-of-field of the camera, meaning both close-up and far away targets cannot both have optimal sharpness. The result is image blur, reduced feature tracking accuracy and inconsistencies in photogrammetry-based mapping applications.

The Deep Vision Optics integrates a corrective optical design with three key objectives: eliminate image blur in the corners, enhance overall image sharpness and expand the depth of field. By optically correcting for the effects of the dome viewport and water medium, the system ensures nearly equal sharpness across the entire field of view, allowing for full-sensor utilization, the company said. In addition, the new optical system removes distortions caused by the water medium, improving clarity in the corners and at the center as well. Moreover, with customized optical engineering, the system enables clear imaging of both nearby and distant objects, which is crucial for precision inspections and wide-area surveys. The system's underwater imaging also enhances situational awareness for ROVs and improves visual surveys with AUVs.

Navigation technology operates in challenging acoustic environments

Teledyne Marine has released the Teledyne Compact Navigator, an ultra-compact and autonomous integrated navigation tool.

Designed for both subsea and surface vehicles, it is ideal for small vehicles and enables inspection and survey applications not previously achievable, the company said. The technology is available in two depth-rated versions: 4,000 m and 300 m. The company also claimed this is the world's smallest high-accuracy navigator, measuring only Ø114 mm x 135 mm, fitting within the volume of most standalone DVLs.

The Compact Navigator's fully autonomous operation is designed to eliminate the need for external aiding or operator intervention. It also features comprehensive connectivity, with power, Ethernet, dual triggers and serial connections accessible via a single connector. The phased array DVL technology is designed to enhance performance while maintaining its compact size, allowing the instrument to sit flus with an AUV or ship hull, the company said.

The tool supports a range of applications, including ROVs, AUVs, shallow-water surface navigation, GNSS-denied environments and dynamic positioning for surface vehicles.

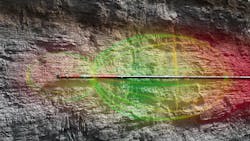

Technology captures high-resolution borehole images

SLB has released its Retina at-bit imaging, which enables identification of formation characteristics. This is designed to optimize drilling efficiency, formation evaluation and safety.

The company said this technology provides precise measurements at first contact between the drillbit and the formation, providing image clarity in large hole sizes as drilling begins and the borehole diameter reduces progressively toward the reservoir section. Retina addresses the limitations of traditional imagers, which are often restricted by operational factors like drilling fluid type and wellbore damage, and often not usable in the reservoir access intervals due to borehole size limitations, the company explained. Applicable to drilling operations utilizing any drilling fluid composition, Retina enables high-resolution imaging, providing critical insights into the formation.

Digital technology provides actionable downhole intelligence

Neo Oiltools has released its Neosmart electronic module, which is designed to transform mechanical motion into actionable intelligence. The technology's high-frequency sensors provide in-depth, high-resolution post-run diagnostics that help maximize drilling performance while minimizing downhole risk, the company said.

As an optional device embedded into Neotork, Neosmart monitors downhole vibrations in 3D and tracks the axial movements of Neotork throughout a run. Operating at a sampling frequency of 1,000 Hz, Neosmart captures detailed dynamic behaviors during drilling. The information is securely stored and then retrieved once the tool is back on the surface to offer a complete and precise reconstruction of the downhole environment.

The data Neosmart provides can guide adjustments in drilling parameters, bit design or bottomhole assembly (BHA) configuration for future runs, delivering more predictable and efficient drilling. By improving the visibility of downhole dynamics and reducing uncertainty, the company said Neosmart helps avoid costly failures and unnecessary trips. Drilling programs can be optimized based on actual operational feedback rather than assumptions, leading to better planning, lower nonproductive time and longer tool life, the company added.

Horizontal look-ahead resistivity service identifies hazards

Halliburton has released its EarthStar 3DX technology with the aim of providing operators with geological insights into horizontal wells up to 50 ft before penetration by the bit.

The company said this is "the industry's first 3D horizontal look-ahead resistivity service." The technology provides users with the capability to gather real-time data, identify hazards and make informed decisions.

"By mapping geological variations before they are encountered, operators can adjust well trajectories to minimize risk, improve wellbore placement and increase reservoir contact," said Jim Collins, vice president, Sperry Drilling, Halliburton.

The EarthStar 3DX look-ahead service enables earlier formation detection. The service helps operators anticipate formation changes, optimize reservoir contact and hydrocarbon recovery, and reduce premature exits and unnecessary corrections, the company said. Early intervention mitigates wellbore instability challenges and facilitates safe and efficient operations.

Module addresses flange failures on FPSOs and more

Akselos has released structural performance management (SPM) for flanges. This new module is designed to enhance asset integrity across industrial sites. The technology addresses flange failures, which the company said is a major source of downtime and maintenance costs across refineries, FPSOs and other critical infrastructure.

In a typical refinery, there are hundreds of thousands of these critical connectors, linking piping systems, pressure vessels and essential equipment across both refineries and offshore platforms. Yet traditional maintenance and analysis are bottlenecks during multimillion-dollar refinery turnarounds, the company said, leading to safety risks, unplanned downtime, costly delays, and directly affect throughput and profitability.

Akselos said its new module significantly cuts flange analysis time from days to hours, making it easier to plan maintenance across large asset bases. It is also designed to help prevent issues like over-tightening, improves safety and ensures product stays contained. The company said this new module allows operators to work up to 80% faster than with traditional methods.

About the Author

Ariana Hurtado

Editor-in-Chief

With more than a decade of copy editing, project management and journalism experience, Ariana Hurtado is a seasoned managing editor born and raised in the energy capital of the world—Houston, Texas. She currently serves as editor-in-chief of Offshore, overseeing the editorial team, its content and the brand's growth from a digital perspective.

Utilizing her editorial expertise, she manages digital media for the Offshore team. She also helps create and oversee new special industry reports and revolutionizes existing supplements, while also contributing content to Offshore's magazine, newsletters and website as a copy editor and writer.

Prior to her current role, she served as Offshore's editor and director of special reports from April 2022 to December 2024. Before joining Offshore, she served as senior managing editor of publications with Hart Energy. Prior to her nearly nine years with Hart, she worked on the copy desk as a news editor at the Houston Chronicle.

She graduated magna cum laude with a bachelor's degree in journalism from the University of Houston.