Safety system concept addresses fall hazards for offshore rig workers

Key Highlights

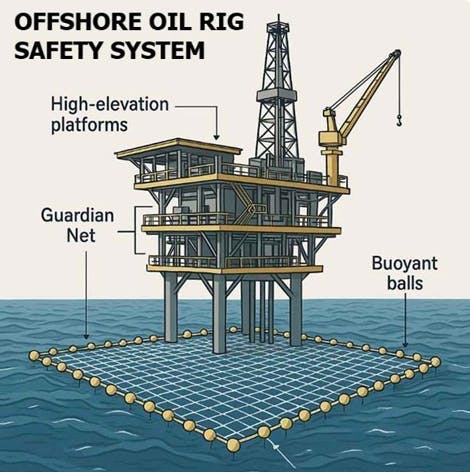

- A corrosion-resistant net would be designed to float on the sea surface directly around the perimeter of an offshore rig.

- Smart IoT sensors would detect impacts or disturbances, triggering immediate alerts for rapid response and rescue coordination.

- The projected development timeline spans the next three to six months.

By Ariana Hurtado, Editor-in-Chief

A new concept, called Guardian Net, aims to enhance worker protection by integrating a floating safety net with real-time monitoring technology. The dual-layered safety system is designed to mitigate offshore risks through a combination of physical and digital safeguards.

The implementation of the system is designed to offer enhanced personnel safety, real-time monitoring and detection alerts, operational continuity that does not interfere with routine rig operations and a modular design that allows for easy deployment and maintenance.

Guardian Net is an independent initiative developed by Uttamkumar Upadhayay, a seasoned IT professional with over 30 years of experience and who is currently consulting for a leading oil and gas company.

He explained that a high-tensile, corrosion-resistant net would be designed to float on the sea surface directly around the perimeter of the offshore rig. Its buoyancy would be maintained by hundreds of strategically distributed yellow buoyant balls, ensuring the net remains afloat and effective, even in challenging sea conditions.

“This physical barrier serves as a crucial last line of defense, designed to safely catch personnel in the event of an accidental fall from the rig,” Upadhayay said.

Complementing the physical net would be an integrated Internet of Things (IoT) sensor network, with smart sensors installed along the rig’s perimeter and at key net anchor points.

“These sensors are engineered to detect disturbances or impacts on the net, such as a worker falling into it,” he added. “Upon detection, the system immediately triggers high-priority alerts in the rig’s central control room. This real-time monitoring capability is vital for enabling rapid response and rescue operations, minimizing the time between an incident and intervention.”

Industry support and development timeline

The initiative remains in the early conceptual and planning stages.

“While no formal financial investment has been secured, the concept has garnered internal interest and informal support from professionals within the oil and gas safety and operations domain,” Upadhayay said. “Discussions are ongoing to identify potential collaborators who align with the initiative’s safety objectives.”

Exclusive content:

AI-powered detection platform deployed on offshore rigs to improve safety

Zelim's technology combines visual hardware with AI software to automatically detect when a person falls overboard and tracks their position in real time.

Opinion: Industry seeing shift from reactivity to proactivity for safeguarding offshore crews

Upadhayay said he was inspired to design this system after a comprehensive review of offshore rig operations and the inherent safety challenges faced by workers.

“The concept is deeply rooted in real-world rig safety concerns, aiming to provide a practical, technology-driven solution to a critical industry issue,” he said. “While currently in the conceptual phase, the system offers a scalable and potentially impactful solution to one of the most pressing safety challenges in offshore operations: falls from height. Its adoption could mark a significant advancement in safeguarding personnel, enhancing the integrity of offshore platforms, and contributing to the industry's overarching goal of achieving zero accidents and fatalities.”

The projected development timeline spans the next three to six months, but the timeline may be adjusted based on the availability of resources and partner engagement.

“This period will be dedicated to refining the concept into a pilot-ready framework, conducting technical validation and engaging with stakeholders to ensure alignment with operational requirements,” he concluded. “Preliminary outreach has been initiated with select offshore operators to assess interest in participating in field trials. While no formal agreements are in place at this time, early feedback has been positive, and further discussions are planned to explore implementation opportunities once a prototype is available.”

NEW RELEASE:

Offshore Safety Systems & PPE Special Report 2025

Emerging safety trends, technological progress and best practices in offshore safety shed light on energy industry challenges.

About the Author

Ariana Hurtado

Editor-in-Chief

With more than a decade of copy editing, project management and journalism experience, Ariana Hurtado is a seasoned managing editor born and raised in the energy capital of the world—Houston, Texas. She currently serves as editor-in-chief of Offshore, overseeing the editorial team, its content and the brand's growth from a digital perspective.

Utilizing her editorial expertise, she manages digital media for the Offshore team. She also helps create and oversee new special industry reports and revolutionizes existing supplements, while also contributing content to Offshore's magazine, newsletters and website as a copy editor and writer.

Prior to her current role, she served as Offshore's editor and director of special reports from April 2022 to December 2024. Before joining Offshore, she served as senior managing editor of publications with Hart Energy. Prior to her nearly nine years with Hart, she worked on the copy desk as a news editor at the Houston Chronicle.

She graduated magna cum laude with a bachelor's degree in journalism from the University of Houston.