Jessica Stump,Assistant Editor

More than 61,300 attendees from 100 countries gathered at the 50th edition of the Offshore Technology Conference in Houston. The exhibition at NRG Park covered more than 585,000 net sq ft and featured 2,300 companies representing 44 countries. Nearly 300 were new exhibitors, and international companies made up 55% of exhibitors.

Subsea

Many products and technologies were introduced for the subsea market.

Houston Mechatronics unveiled Aquanaut, a multi-purpose subsea robot which employs a patented shape-shifting transformation from an autonomous underwater vehicle (AUV) to a remotely operated vehicle. The vehicle, which removes the need for vessels and tethers, enables both the efficient collection of data over long distances as well as manipulation of subsea objects at a lower cost than today’s technology.

The Aquanaut transforms from an AUV to an ROV. (Courtesy Houston Mechatronics)

TechnipFMC launched Subsea 2.0, a ‘product platform’ designed to make subsea projects simpler, leaner, and smarter. In combination with iEPCI, the company’s integrated approach to field architecture and project execution, Subsea 2.0 should also improve project economics and deliver first oil and gas faster. The goal of iEPCI is to transform subsea projects through the full field development process by integrating front-end design and life of field to streamline project execution. The new combination is intended to advance progress further by combining ‘expert’ teams to rethink how subsea production could be more efficient.

Subsea 2.0 comprises six core products that combine field-proven and new technologies. They include the compact tree, compact manifold, flexible jumpers, distribution, controls, and horizontal connectors.

According to the company, the smaller, lighter products can achieve a reduction of up to 50% in size, weight and part count, while maintaining the same or better functionality.

The new platform is designed to accommodate iEPCI using LEAN product and process engineering, and has been standardized to be configurable to client needs and optimized to improve performance over the life of the field. This should result in a 70-90% reduction in manual activities during the production process, the company claims, with faster hardware delivery times.

The Wellhead Defender subsea isolation cap on H-4 wellhead fixture. (Courtesy Universal Subsea Inc.)

Universal Subsea Inc. unveiled the patent-pending Wellhead Defender subsea isolation cap. According to Sean Thomas, founder and general manager, “…Used in conjunction with our Defender Stasis isolation fluids, the Wellhead Defender subsea isolation cap effectively prevents corrosion and marine growth on critical sealing and locking features of subsea wellheads, preserving the subsea wellhead in a stasis condition.”

The company said that it spent more than 2,000 hours analyzing, selecting, testing, and qualifying the one-piece, corrosion-proof, thermoplastic body. In contrast, metal subsea protector caps can foster corrosion. It added that competing subsea protector caps typically have ineffective body seals, allowing isolation fluid to quickly leak out to the ocean.

Digital technologies

Digitalization was a key theme at the event. Not only did many digital technologies debut, but also a few partnerships emerged to leverage these platforms.

ABB introduced its Ability Process Performance Dashboard. This is designed to help operators use the increasing amount of data they are generating to quickly identify and fix performance weaknesses. The cloud-based service measures the performance of oil and gas facilities against various indicators, including start-up time and operator interventions. A 150-strong team at the ABB Ability Collaborative Operations Centre in Oslo, Norway, then analyzes the data, with results fed back via the dashboard, revealing areas of improvement and suggesting potential solutions. The company claims that a well-managed approach to process performance improvement can increase production by around 5%, so on a 50,000-b/d platform (in an oil price environment of $50/bbl), this would generate an additional $35 million in annual revenue.

Stress Engineering Services launched NeoSight, an asset integrity management platform. The primary goal of the new platform is to incorporate hindsight, insight, and foresight into the evaluation of asset performance and integrity, for a range of industries and applications. The platform leverages and supplements new or existing digitalization efforts, integrating directly with existing business systems in real-time or near real-time. This reduces the time to action from days or months to minutes.

A physics-based digital twin model is built into each NeoSight tool, which accurately simulates asset response. Digital twin models allow for the integration of inspection, analysis and measured data, providing important, previously unavailable insights into asset behavior.

Clarus Subsea Integrity, an Acteon company introduced the iCUE Digital Anomaly Detection App. This new technology is said to provide rapid and accurate detection of anomalies by reviewing inspection video footage of subsea assets.

Flexlife and Rio Analytics signed an exclusive partnership agreement to use artificial intelligence (AI) to monitor subsea risers and structures. Flexlife will use Rio Analytics’ Artificial Neural Network (ANN) Solutions in the Gulf of Mexico and further afield. The virtual sensors embedded within the ANNs will allow oil and gas operators to accumulate reliable, long-term data from subsea areas which are impossible for real sensors to measure - such as measuring flexible risers or SCR stress on a FPSO.

i-Tech Services, a Subsea 7 company, and Leidos have signed a five-year digitalization partnership agreement. The partnership will increase efficiencies in i-Tech Services’ Life of Field capabilities by providing greater insights into operations through the field lifecycle. This relationship will leverage Leidos’s multi-sector expertise in digitalization and enable i-Tech Services to automate manual processes, reduce operating costs and use innovative technologies and capabilities to further differentiate its offerings.

Drilling and production

Companies unveiled technologies for the drilling and production market.

Balmoral Offshore Engineering introduced a drill riser buoyancy system that incorporates low drag vibration and suppression capabilities. During the development, the company conducted wide-ranging computational fluid dynamics and fluent modeling, with SINTEF Ocean performing tank trials to provide information needed for the final product design.

Drilling risers extend from the drilling vessel to the BOP, their main function being to provide fluid communications between the well and the vessel. Buoyancy modules fitted around the riser provide uplift while reducing the joints’ submerged weight. However, drilling risers are at risk of potentially catastrophic motions caused by subsurface vortex-induced vibration and drag.

Balmoral DuraFloat LDV is an integral part of the riser buoyancy module that is molded into the product during manufacture; Balmoral DuraGuard LDV is a retrofit option that is applied to existing infrastructure. (Courtesy Balmoral Offshore Engineering)

Balmoral DuraFloat LDV and Balmoral DuraGuard LDV, respectively integrated and retrofit VIV suppression solutions, are designed to prevent such motion occurring in all water depths encountered in E&P. Both products have patents pending. The LDV profile was influenced by the outer structure of a sea turtle’s upper shell which provides an efficient and low-drag hydrodynamic structure. Balmoral’s team simulated this natural structure by implementing biomimetic engineering to achieve the required VIV and low drag performance.

The company claims the hex design eliminates the need for ancillary suppression equipment to be attached to the riser, offering improved timings when running and removing drill stacks. Another benefit of reduced riser motion is improved fatigue performance of subsea equipment, which helps cut costs by extending the service lives of wellhead and conductor/casing equipment.

Balmoral DuraFloat LDV is an integral part of the riser buoyancy module that is molded into the product during manufacture; Balmoral DuraGuard LDV is a retrofit option that is applied to existing infrastructure. The products are said to be suited to marine drilling and production risers, umbilicals, flowlines and power cables.

InterMoor introduced the Inter-M Release mooring connector. Acoustic release mooring connectors allow a rig’s mooring legs to be released remotely and immediately, should emergencies or severe weather arise, or alternatively to save time and money during rig moves. The new system, the company claims, is one-quarter of the weight of, and occupies one-third of the deck space needed by, other acoustic release connectors. Its control system, developed with Teledyne Marine, employs military-grade, high-fidelity Teledyne Benthos acoustic modems, and implements domain key authorization, network relay and frequency hopping techniques. These, InterMoor says, ensure the mooring connectors are unaffected by obstructions or conflicting noise and eliminate the possibility of an inadvertent release, with the potential to actuate the connector individually, in clusters, or sequenced in any order. Battery life is five years, compared with 18 months in old acoustic release connectors. The system is currently undergoing DNV and ABS class certifications.

Halliburton debuted InnerVue non-intrusive pipeline and wellbore diagnostics. This technology is said to quickly and accurately detect blockages or leaks and profiles deposits in pipelines and wellbores. Without the need for intrusive intervention, InnerVue diagnostics interprets pressure waves reflecting from internal features of the pipeline or wellbore and extrapolates the pressure reflections into deposit profiles or blockage and leak locations. A proprietary software analyzes the pressure wave signature to determine the profile of the hydraulic diameter of a pipe or wellbore, detecting blockages such as stuck pigs or the top-of-a-cement plug, and identifies fluid leakage locations and volume.

The Icemann is installed on theStepan Makarov, a new ice-class platform standby vessel built for the Sakhalin-2 project. (Courtesy Ampelmann)

Spotlight award winners

Seventeen new and innovative products and services from 14 exhibiting companies garnered the OTC Spotlight on New Technology Award.

Ampelmann earned the award for the N-type gangway. Nicknamed Icemann, the N-type is designed to safely and efficiently transfer crew in extreme icing and temperatures as low as -28°C (-18°F). The fully enclosed and insulated system is operational in sea states up to 3.5 m (11 ft) significant wave height and comprises active motion compensation. The system can rotate to 360 degrees and is controlled from the vessel with flexibility in platform landing locations and directions. It is certified under the winterization design code DNV-GL-OS-A201.

Oceaneering won the award for the E-ROV, a self-contained, battery-powered remotely operated vehicle system. Comprising an electric ROV, 4G connection buoy, and subsea cage, the system can operate for extended periods of time without being recovered to the surface, which reduces cost and risk.

The 10K completion workover riser flexible joint accommodates the motion of the vessel up to a 10-degree cocking angle. (Courtesy LORD Corp.)

LORD Corp. was recognized for the 10K completion workover riser flexible joint. This high-pressure joint accommodates the motion of the vessel up to a 10-degree cocking angle. The flexible joint offers a dual-bearing design, where each bearing is comprised of multiple layers of elastomer bonded to spherical reinforcements. It allows smaller vessels to operate a top-tensioned riser without a stress joint or telescopic joint, enabling lower cost high-pressure interventions. It offers a 10,000-psi operating pressure with a 15,000 psi hydrotest and can be rated up to a temperature of 177°C (350°F).

Dril-Quip Inc. won for the HFRe drilling riser. This is an automated system designed for high-pressure/high-temperature applications with efficient operations incorporating SmartSpider technology. This technology reduces risk and operational costs by providing critical feedback and eliminating rig floor personnel during installation. The drilling riser uses a boltless, fatigue-resistant 4-million-lbf coupling which has been tested beyond API 16F/TR7 requirements.

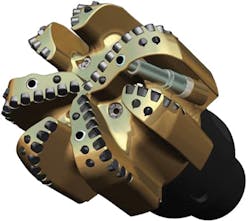

The TerrAdapt adaptive drill bit is designed to automatically adjust to changes in geological formations. (Courtesy BHGE)

Baker Hughes, a GE company received two Spotlight Awards. The first is for the TerrAdapt adaptive drill bit, which autonomously adjusts depth-of-cut to mitigate stick/slip and expand the smooth drilling window with no surface interaction.

The second is for the DEEPFRAC multi-stage fracturing service. This leverages tools and techniques perfected in unconventional plays to improve the efficiency and economics of offshore completions. Using ball-activated sleeves and patented BeadScreen flowback control technology, the service simplifies operations, accelerates completion times, and enables rapid stimulation of 20+ stages in a single trip.

Halliburton also won two awards. The first is for the GeoBalance automated managed pressure drilling (MPD) system. This is a comprehensive suite of software and hardware enabling automated managed pressure control from drilling to completion. It combines automatic chokes, rig pump diverters, flow metering, and advanced control algorithms with proven hydraulics modeling to provide accurate pressure control at discrete points throughout well construction.

The GeoBalance automated managed pressure drilling system is a comprehensive suite of software and hardware enabling automated managed pressure control from drilling to completion. (Courtesy Halliburton)

The second is for the 9½-in. azimuthal lithodensity (ALD) logging-while-drilling (LWD) service from Halliburton Sperry Drilling. This is said to be the industry’s first large-borehole LWD service capable of delivering azimuthal density, photoelectric, and ultrasonic caliper measurements to enhance reservoir understanding and reduce well time in borehole sizes ranging from 14½ in. to 17½ in.

Teledyne Marine earned the award for the FlameGuard P5-200 electrical penetrator. This is a flame-proof ceramic electrical penetrator for use as part of the fire-resistant envelope of an offshore surface wellhead and christmas tree system. The penetrator is a key technology element in a 5 kV electrical feedthrough system that provides three-phase power to downhole electrical submersible pumps in offshore dry trees. The penetrator is rated as fire resistant in accordance with API 6FB, Part II.

The penetrator, rated for 5 kV and 200 A at 5,000 psi, is designed for safe operation in potentially flammable atmospheres where ATEX and IEC Ex standards apply, such as those found on offshore platforms.

Luo Yang Wire Rope Inspection Technology Co. Ltd. (TCK.W) earned the award for the online automatic wire rope inspection system. This, the company claims, will revolutionize periodic human visual inspection and bring in-process safety monitoring to its highest state through continuous inspection during operation. TCK.W also received the Small Business Award.

Expro won for the next generation landing string for subsea well commissioning and intervention. This in-riser well intervention technology comprises a five-phase program of work to deliver a complete landing string package, including a range of new functionality across its 73⁄8 valves. It incorporates a high debris tolerant ball mechanism and hydraulic latch mechanism, dual seal protection for both environment and control systems, increased cutting capability, and a fail ‘as is’ retainer valve with the ability to close after a blowout preventer shear scenario. Delivered in accordance with new API 17G standards, the landing string is certified safety integrity level 2 compliant.

The Seabox provides disinfection and sedimentation capabilities without adding chemicals. (Courtesy NOV)

National Oilwell Varco (NOV) earned two awards. The first is for NOVOS, a reflexive drilling system. It allows drillers to automate repetitive drilling activities and focus on consistent process execution and safety, allows operators to optimize drilling programs. The NOVOS system is said to provide the ultimate control and consistency for any operation.

The second is for Seabox, a subsea water treatment system. Driven by the suction pressure of a downstream pump, the system provides disinfection and sedimentation capabilities without adding chemicals.

Delmar Systems Inc. was recognized for the next generation of Rig Anchor Release (RAR). The RAR Plus gives drilling rigs the capability to completely release from their moorings within minutes to evade ice floes, cyclonic storms, well emergencies, or to simply increase rig move efficiency. With a backup mechanical release function, the system is said to provide reliable flexibility to DP/moored rigs operating in shallow water.

Oliden Technology was recognized for the GeoFusion 475 laterolog resistivity and imaging LWD tool. Co-developed with China National Petroleum Co., it delivers focused quantitative array laterolog resistivity measurements and high-resolution images while drilling. The tool provides both improved depth of investigation and enhanced image quality and increased capability for boundary detection and geosteering.

CoreAll earned the award for the intelligent coring system. This, the company claims, is the first core drilling technology to provide real-time transmission of formation evaluation data to surface. Along with downhole diagnostics and core jam indicators, this improves data quality and saves time and cost in exploration activities. The company also won the Small Business Award.

Aegion Coating Services won for the ACS HT-200. This is an ultra-high temperature subsea wet insulation system for pipelines, risers, field joints, and subsea equipment with operating temperatures up to 204°C (400°F). This end-to-end deepwater solution is comprised of an anticorrosion coating covered with an insulation layer and topped with a tough polypropylene exterior.

The conference and exhibition return to NRG Park May 6-9, 2019.