Wärtsilä exec explains how alternative fuels and digital tech are reshaping offshore vessel design

Key Highlights

- Alternative fuels, such as ammonia, methanol, LNG, hydrogen and biofuels, are becoming viable options for offshore vessels within the next decade.

- Safety considerations include managing toxic leaks, cryogenic burns and fire hazards; necessitating rigorous crew training; robust containment systems; and emergency protocols to ensure safe handling of sustainable fuels offshore.

- Digital technologies are crucial for optimizing vessel performance, reducing emissions and maintaining safety in complex offshore operations.

By Ariana Hurtado, Editor-in-Chief

As the offshore energy industry continues its transition toward low-carbon operations, the choice of alternative fuels has become a defining challenge for vessel owners and operators. From ammonia and methanol to LNG, hydrogen and biofuels, each option presents unique technical, economic and safety considerations.

Wärtsilä Marine is developing fuel-flexible solutions that enable operators to adapt to the evolving energy landscape. Offshore spoke with Jon Inge Buli, head of offshore at Wärtsilä Marine, to explore the viability of these fuels, the role of digital technologies and the roadmap for meeting decarbonization targets.

Offshore: Which alternative fuels—such as ammonia, methanol, LNG, hydrogen or biofuels—do you see as most viable for offshore operations in the next 5-10 years, and why?

Buli: The entire maritime industry, including the offshore segment, faces a “chicken-and-egg” problem. Shipowners and operators are hesitant to go all in on one sustainable fuel, especially when such fuels are only being produced in small quantities today. Forward-thinkers are already adopting engines capable of running on sustainable fuels in the future, when these fuels become more readily available, with an increasingly large portion of fuel-flexible vessels being ordered as newbuilds and for retrofit.

Against this backdrop, vessel designs are now being specified with readiness for alcohol-based fuels and biofuels. For instance, Brazilian Newbuild Subsea tenders have now begun to include the ability to run on ethanol as a firm requirement.

Beyond the fuels themselves, hybridization is becoming a common specification, with growing requirements for battery integration, variable-speed gensets and DC grid systems to further enhance operational flexibility and efficiency. Investing in fuel-flexibility allows operators to adapt to changing fuel supplies and market price fluctuations, minimizing risk and ensuring they can use the most viable option as the industry evolves.

Offshore: What are the key safety considerations when handling and storing alternative fuels on offshore platforms and vessels?

Buli: Key safety considerations when handling sustainable fuels in shipping include the risks of toxic leaks, cryogenic burns, corrosive spills and explosive fire hazards. Methanol and ammonia are toxic, with low concentrations posing fatal inhalation risks, while hydrogen’s extreme flammability can lead to dangerous fires and cryogenic burns. Methanol requires double-walled piping to prevent fires, and LNG must be stored in insulated cryogenic tanks to avoid spills.

Addressing these hazards demands rigorous crew training, regular inspection and maintenance of containment systems, strict operational protocols, and robust emergency response measures. Together, these precautions are essential for protecting both crew and the environment, supporting a safe and effective transition to alternative fuels across the maritime industry.

Drawing on our extensive experience with LNG in offshore operations, Wärtsilä has already demonstrated that it is possible to transition safely to alternative fuels within the industry, but this is something that we continue to build upon.

Offshore: What role do digital technologies and real-time monitoring play in optimizing fuel efficiency and emissions performance across offshore fleets?

Buli: The maritime industry has grown increasingly complex, requiring advanced technology, real-time data and analytics to ensure efficient and competitive operations while also staying in line with decarbonization objectives. Digital technologies, such as digital twins for example, allow operators to create virtual replicas of vessels, making it possible to test scenarios safely, optimize hull and engine performance, extend vessel lifespan, and lower maintenance costs. These tools also enhance safety by comparing real-time vessel behavior to stability models.

Predictive maintenance tools, which use real-time vessel data to detect potential issues and assist in optimizing operation and maintenance, are also gaining traction. By leveraging advanced AI capabilities, offshore owners and operators can identify anomalies early and address emerging issues proactively, thereby reducing the risk of unexpected downtime.

By integrating these types of digital tools, among many others, shipowners can boost efficiency, cut emissions and stay competitive.

Offshore: What is Wärtsilä’s current roadmap for integrating future fuels into offshore vessel propulsion systems, and how does it align with industry decarbonization targets?

Buli: Wärtsilä already offers a wide range of flexible and efficient marine engines and gensets that can run on gas, diesel, methanol, ammonia or dual fuel. These engines address multiple challenges faced by the offshore segment, as well as the wider shipping industry generally. For one, these engines and gensets comply with stringent emission standards.

Wärtsilä is also researching ethanol as a sustainable fuel option for both ships and land-based uses, as it will play a major role in reducing greenhouse-gas emissions in the multi-fuel future of shipping.

Wärtsilä also offers fuel-flexible engines in the portfolio, which are designed for later conversion to alternative fuels. Not only this, but Wärtsilä’s marine engines and gensets are designed for maximum performance and uptime.

Commercially viable clean fuels for the future is a key focus area of our research and development (R&D); we invest ~4% of net sales in R&D. For example, during 2024, R&D expenditure totaled EUR 296 million [US$344.7 million], which represented 4.6% of net sales last year.

Offshore: How is Wärtsilä addressing the technical challenges of fuel compatibility and retrofitting existing offshore assets for multi-fuel capability?

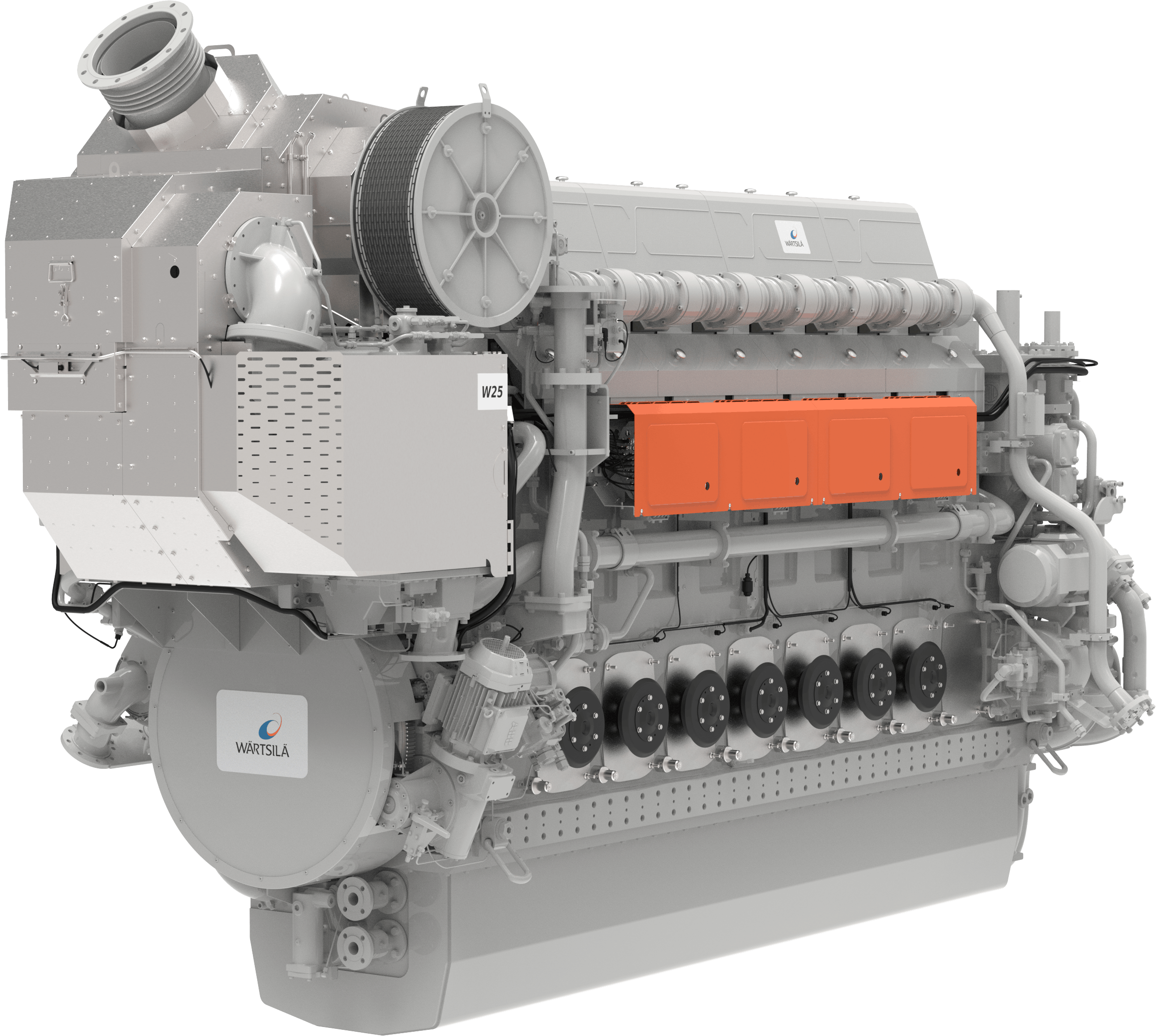

Buli: Most ships today have the potential to operate for 20 years or more, so it’s important they can be adapted to fit new requirements over time. The latest engines in our portfolio have been designed with a future-proof, upgradeable module structure for faster, easier upgrades and conversions to sustainable fuels. For example, the Wärtsilä 25 engine is a medium-speed, four-stroke marine engine. It can run on diesel, dual-fuel LNG and now also dual-fuel ammonia. Because of the modular design, less time-intensive modifications are needed to make the engine work with sustainable fuels. If ship owners plan ahead for the storage needs of these fuels, they can build ships today that are ready to switch to new fuels when needed.

For older vessels, which might not currently benefit from these types of modular engines, it is also possible to modify the equipment to run on sustainable fuels. This, of course, depends on a number of factors, including but not limited to the type of fuels, load and operating profile, certification, space and safety requirements. Where it is possible, Wärtsilä delivers the full project from feasibility studies, financing solutions, execution planning and implementation, to full engineering, procurement and construction solutions. Since every project is unique, our approach is flexible and adaptable to individual customer needs.

Offshore: How is Wärtsilä collaborating with offshore energy operators, regulators and classification societies to accelerate fuel innovation and standardization?

Buli: The global nature of shipping means working together with others is the only way the industry can unlock the potential to drive sustainable transformations and develop technologies and solutions that meet the needs of the wider value chain. We regularly partner with organizations, such as regulators, classification societies, shipowners, operators, suppliers, research institutions and more, from all over the world in the development of new, sustainable fuels.

Let’s take ethanol as a marine fuel for example. As Wärtsilä sees an important role for ethanol in shipping’s multi-fuel future, we have been collaborating with shipowners and energy providers in Brazil to verify its potential as a sustainable fuel. For example, we are working with Brazilian company Raízen to test ethanol in one of our multi-fuel platforms.

Cooperating with like-minded partners, such as Raízen, CMM and Energetica Suape II S.A, is vital to achieving significant advances in maritime decarbonization.

About the Author

Ariana Hurtado

Editor-in-Chief

With more than a decade of copy editing, project management and journalism experience, Ariana Hurtado is a seasoned managing editor born and raised in the energy capital of the world—Houston, Texas. She currently serves as editor-in-chief of Offshore, overseeing the editorial team, its content and the brand's growth from a digital perspective.

Utilizing her editorial expertise, she manages digital media for the Offshore team. She also helps create and oversee new special industry reports and revolutionizes existing supplements, while also contributing content to Offshore's magazine, newsletters and website as a copy editor and writer.

Prior to her current role, she served as Offshore's editor and director of special reports from April 2022 to December 2024. Before joining Offshore, she served as senior managing editor of publications with Hart Energy. Prior to her nearly nine years with Hart, she worked on the copy desk as a news editor at the Houston Chronicle.

She graduated magna cum laude with a bachelor's degree in journalism from the University of Houston.