Lower emission, higher efficiency tanker

Ship designs need to be more fuel efficient and environmentally friendly. Ecoship Engineering has taken a major step toward this goal by developing a completely new vessel that could be adapted for shuttle tankers on offshore projects. The vessel has been designed in collaboration with Swedish shipping companies, the Chalmers University of Technology in Gothenburg, and the National Swedish Administration of Shipping and Navigation.

At the heart of the new design is a diesel-electric power plant comprising multiple high-speed, low-emission diesel engine generating sets. These produce power for the electric motors that drive the propellers, and also supply other power demands elsewhere on the ship. The generating sets are controlled through a computerized power management system which alters the number of engines online depending on the ship's power demands.

The hull is a new patented design that reduces water resistance in the higher speed ranges. The hull will be constructed mainly of single bent plates to provide a smooth efficient design. The new hull will be able to carry more cargo because there is no engine room taking up cargo space.

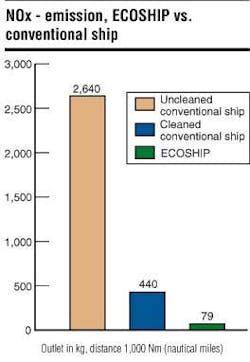

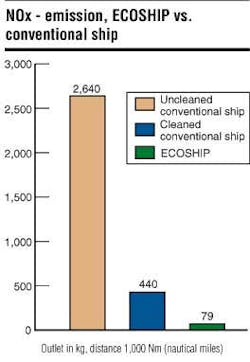

One of the primary goals of the project is to create a low emission system that will comply with IMO maritime and EC emission rules. Each engine will operate on low sulfur diesel fuel and send its exhaust through a catalytic converter system to minimize nitrogen oxide and particulate emissions. Significant reductions in raw hydrocarbons, carbon monoxide, sulfur dioxide, and soot are expected. The combination of high speed diesel engines with catalytic converters will lower emissions up to 95% over conventional ships.

As an example of the Ecoship, a 10,600-cu-meters oil product tanker would have an overall length of 120 meters, a breadth of 17.5 meters, and a draft of eight meters, with a maximum weight of 8,500 deadweight tons.

For more information, contact Björn Carlsson, Ecoship Engineering. Tel: +44 (0)40 34 81 40, Fax: +46 40 34 83 86, E-mail: [email protected] .