DEEPWATER DRILLING:New deep draft semi designed for marginal GoM fields

Jennifer Pallanich Hull

Gulf of Mexico Editor

To meet a market focused on econo-mically extracting oil from marginal fields beyond the reach of subsea tiebacks, Aker Kvaerner Inc. has designed a deep draft semisubmersible for marginal deep-water Gulf of Mexico fields.

AK is marketing the concept at marginal fields of 30-80 MMbbl, with output of 40,000 b/d from subsea wells. With around 60% of deepwater GoM fields thought to contain 60 MMbbl or less, many of these fields are uneconomical to develop with traditional means, said AK Senior Vice President Knut Eriksen.

The concept offers the flexibility of re-location and targets marginal fields, which typically have a short field life.

After the initial field is depleted, the semi can be towed ashore to modify the process for a new field, and the platform can be towed to the new location. The simplicity of these operations should give the semi a good second-hand value and a potential for depreciation over more than one project, said AK Deepwater Technology Team Leader Henrik Hannus. He said the concept is designed as a newbuild and that conversion of existing semis would not be able to provide the same motion characteristics.

AK conceived the deep draft semi around existing design philosophy for minimal facility developments. The deep draft semi idea came out of in-house market analyses on the deepwater discovery size distribution as well as the market trend toward subsea wells in ultra deepwater, Eriksen said. The concept was developed for a bid, he said, and it was tested at the Offshore Model Basin in California in July 2002. The model confirmed the motions that were predicted, he said, adding AK was pleased with the outcome of the test.

In a hurricane, waves will run through the deck truss, he said, noting a similar deck design is already in use in the Njord field in 330 m of water in the Norwegian Sea.

"We have tried to stay with structural designs from things we have built," Hannus said, noting the rectangular pontoons that make an appearance at Snorre B and in the deep draft semi design.

The design is not intended for plans calling for a dry tree solution, rather for fields requiring a subsea tieback.

Working with semis and steel catenary risers (SCRs) can be difficult, he said, so the company designed a semi around the SCR rather than taking an SCR and trying to add the semi.

"It's a package that holds together," he said.

Hannus said the deep draft semi, with polyester mooring, could be used in fields to 10,000 ft. A benefit of the design, he said, is that there is no clear threshold on water depth.

Structure, construction

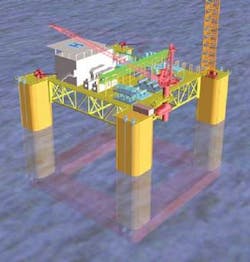

The deep draft semi features a ring pontoon. Other hull characteristics include simple node with no casting, central access column, and simplified hull systems. The flat truss deck is skid-based and promotes simple integration of topside facilities.

AK deviated from normal semi design by not placing equipment in the columns. Hannus noted that TLPs and Spars also refrain from placing equipment in the columns. While the move means ballast, which is more important when drilling is involved, cannot be shifted from one column to another, it also simplifies the system, he said.

null

The entire unit requires significantly less steel than a Spar, Hannus said, noting the flat deck requires simpler fabrication than a multilevel deck.

The deck would be fabricated with the truss deck and skids on top before being lifted onto the hull with a quayside heavy lifting device. The hull and deck would then be towed to the field, where moorings and risers would be hooked up and the unit would be commissioned. Performing the lift at quayside rather than offshore reduces risk and potential for weather delays thereby improving project safety, Hannus said.

For now, the basic design is complete, ready for adaptation to a field-specific situation, Eriksen said.