ROV technology alone isn't enough for successful subsea operations

Key highlights:

- Teamwork, communication and adaptability are essential for successful ROV operations in dynamic offshore environments.

- Tether management poses significant risks; proper handling and awareness of sea state and vessel movement are vital to prevent vehicle loss.

- Pre-dive and post-dive checks, along with collaborative troubleshooting, help maintain system integrity and address faults efficiently.

- Team awareness and quick thinking can save hours of work and improve operational outcomes.

By Matt Simpson, Forum Energy Technologies

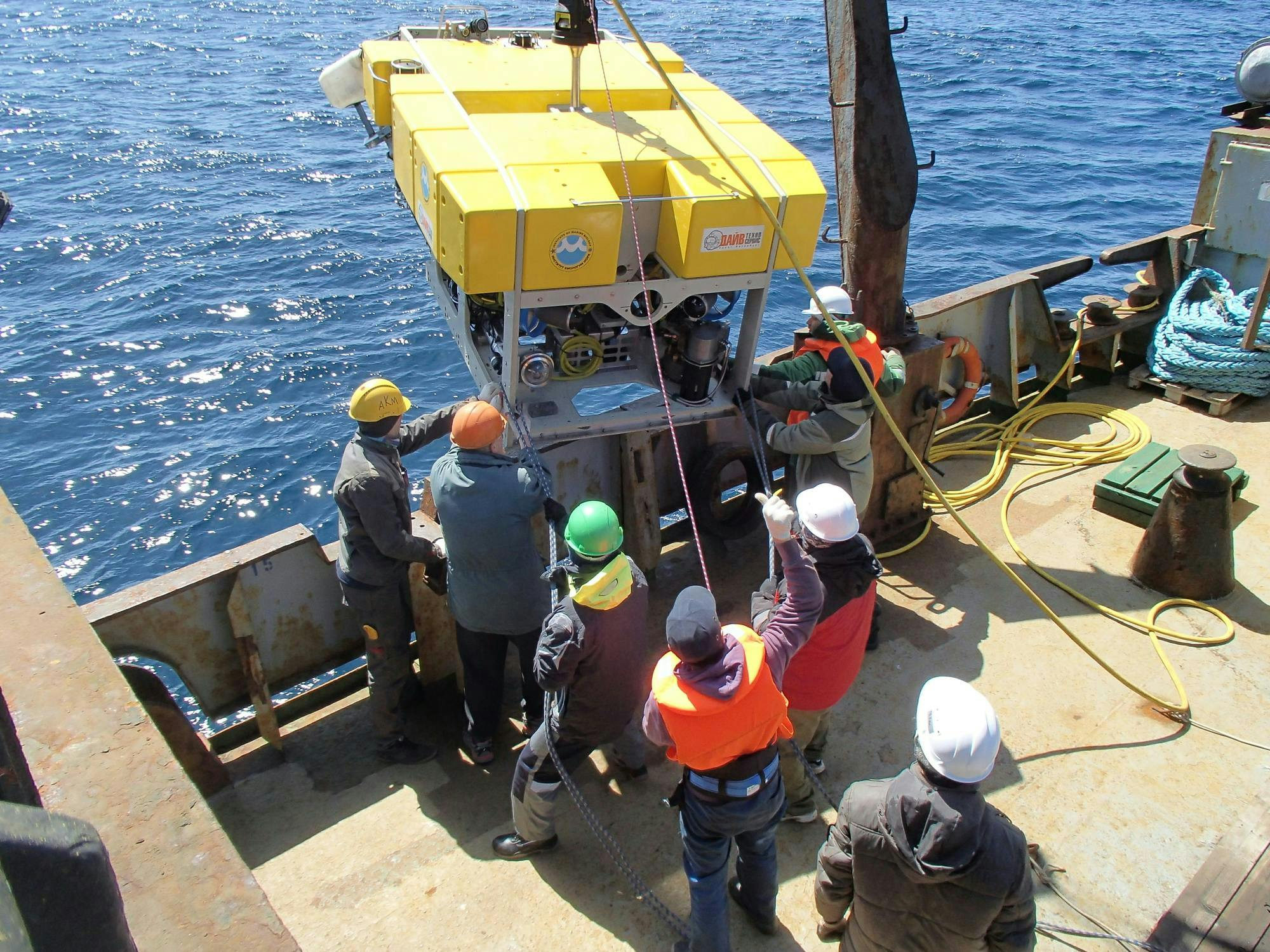

No matter how advanced ROV technology becomes, the success of any operation always comes down to teamwork. It is easy to focus on the vehicles themselves—the thrusters, manipulators, sensors and software—but these are redundant without the correct people at the controls. ROV work is demanding and constantly shifting, and it relies on a group of individuals who communicate, support and adapt to each other’s strengths in high-pressure environments.

A typical ROV team is made up of a pilot, co-pilot and supervisor, though roles are rotated depending on the job and length of shift. Piloting requires intense concentration, and while an hour in the chair is usually enough before swapping out, there are days when the pilot sits for much longer periods because the work demands it. What matters is that everyone’s understanding goes beyond their own role. The team needs a shared understanding of the task, the conditions and the sequence of events, especially when two ROVs are in the water at the same time. In those situations, ROV operators must remain aware of their own tether and the other vehicle’s too, along with the crane and vessel movements, as well as deck crew activity.

Communication ties it all together. Offshore, personnel are constantly talking—to the offshore construction supervisor on the bridge, sometimes the crane operator and even the variable lay system team. There is also the rigging crew in the back deck and other ROV to consider.

Most vessels use a shared control room so everyone can follow the same operational picture. Even then, clear communication is essential because subsea conditions change quickly. Currents and visibility shift, and equipment can behave differently than expected, meaning plans must be adapted. When the communication works, the whole team moves as one; when it doesn’t, things unravel very quickly.

Tether management

Much of the risk revolves around tether management. If a tether is damaged or lost, the operator can lose the vehicle. So, everyone stays alert to sea state, current direction and how the vessel is behaving.

Recoveries are often the most challenging moments. Surface currents can be far stronger than those at depth. So, just as the ROV reaches the splash zone, it may try to drift away from the vessel.

Docking into the tether management system can also be challenging. Some vessels have heave-compensated systems that make the process easier, but many older ones do not, and it is important to time the docking process correctly and guide the vehicle back into the tether management system without impact.

Maintenance checks

Case study

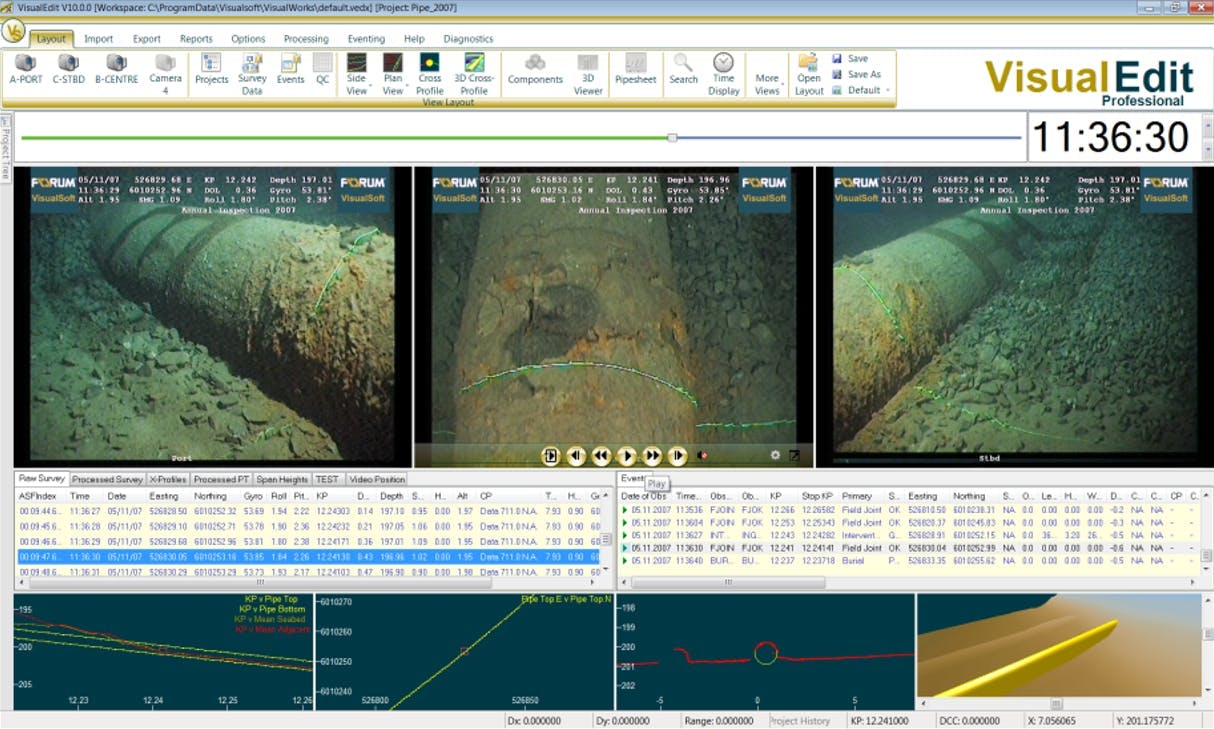

During a recent subsea project, a hydraulic cutter developed a loose fitting on the seabed, and recovering it to deck would have meant an hour and a half of lost time. Someone on the team, however, was mindful of the intricacies of the tool and had stowed a spanner in a work basket from an earlier task. The FET team was able to guide the ROV to the basket, pick up the spanner with the manipulator and tighten the fitting subsea. This resulted in hours saved, and it only worked because several people pieced the solution together.

Next gen advice

For anyone entering the industry, learn the system, stay curious and rely on your team. Technology helps the industry reach incredible depths, but it is the people communicating and thinking ahead who make the work possible. Offshore operations succeed because no one does them alone.

About the Author

Matt Simpson

Matt Simpson has always had a passion for manufacturing and engineering, starting with classic cars. His experience comes from being hands on both inside and outside of work, working mostly in technical roles as well as some commercial ones. This experience ties in well with his role as systems support manager at Forum Energy Technologies (FET), where he supports a wide range of manned and remotely operated subsea vehicles across the globe as well as many other subsea products.