Subsea raw water injection at Buzios tackling topside constraints and driving recovery offshore Brazil

By John MacLeod, SLB OneSubsea

Water injection has long played a part as an enhancer of secondary oil recovery, but its implementation offshore Brazil, particularly in the sprawling presalt fields, has been complicated by unforeseen capacity deficits that are now putting a strain on valuable FPSO real estate. As these assets mature, the need for efficient, scalable injection solutions is growing.

The Buzios Field, operated by Petrobras, is a good example of this trend, where subsea water injection was identified as an attractive, resource-efficient strategy to boost production in this maturing field. SLB OneSubsea is providing two subsea raw water injection (RWI) systems, which have been designed to enhance injection directly at the seabed, freeing up topside real estate for more valuable use. This case study examines the drivers, implementation and potential longer-term implications of a broader roll-out of subsea injection systems.

Maturing fields and operational constraints

Brazil’s presalt developments are defined by scale, complexity and a continuous drive for operational efficiency. Buzios, one of the world’s largest deepwater oil fields, has produced significant volumes of hydrocarbons since its inception. As with many producing assets, however, the natural reservoir drive is depleting. This is being addressed by a range of secondary recovery methods, including subsea RWI, to ensure that the full asset potential is realized.

Today, operators in Brazil face a confluence of factors:

- Topside real estate: FPSOs offshore Brazil are routinely constrained by space and capacity. Retrofitting or expanding topside water treatment and injection infrastructure can be costly, disruptive and often impractical.

- Operational power supply: Electrical capacity is at a premium. Placing equipment on the seabed fundamentally reduces the energy required to achieve the same outcome as a topside solution. By avoiding the pressure drop in the pipeline and leveraging the proximity to the well, efficiency is optimized and power consumption is minimized.

- Reservoir dynamics: Aquifer activity over time has led to reservoir depressurization, further heightening the urgency for effective water injection.

The challenge at Buzios was twofold: restore and maintain reservoir pressure to halt production decline and do so while managing topside constraints and power supply challenges.

Technical overview: subsea raw water injection

The resurgence of subsea water injection reflects both the advancing maturity of subsea pump systems and a shift in the cost-benefit equation. The systems designed and delivered by OneSubsea for Buzios are built on tried and tested building blocks—supported by more than 5 million hours of rotating equipment operation on the sea floor—purposely adapted for seawater injection.

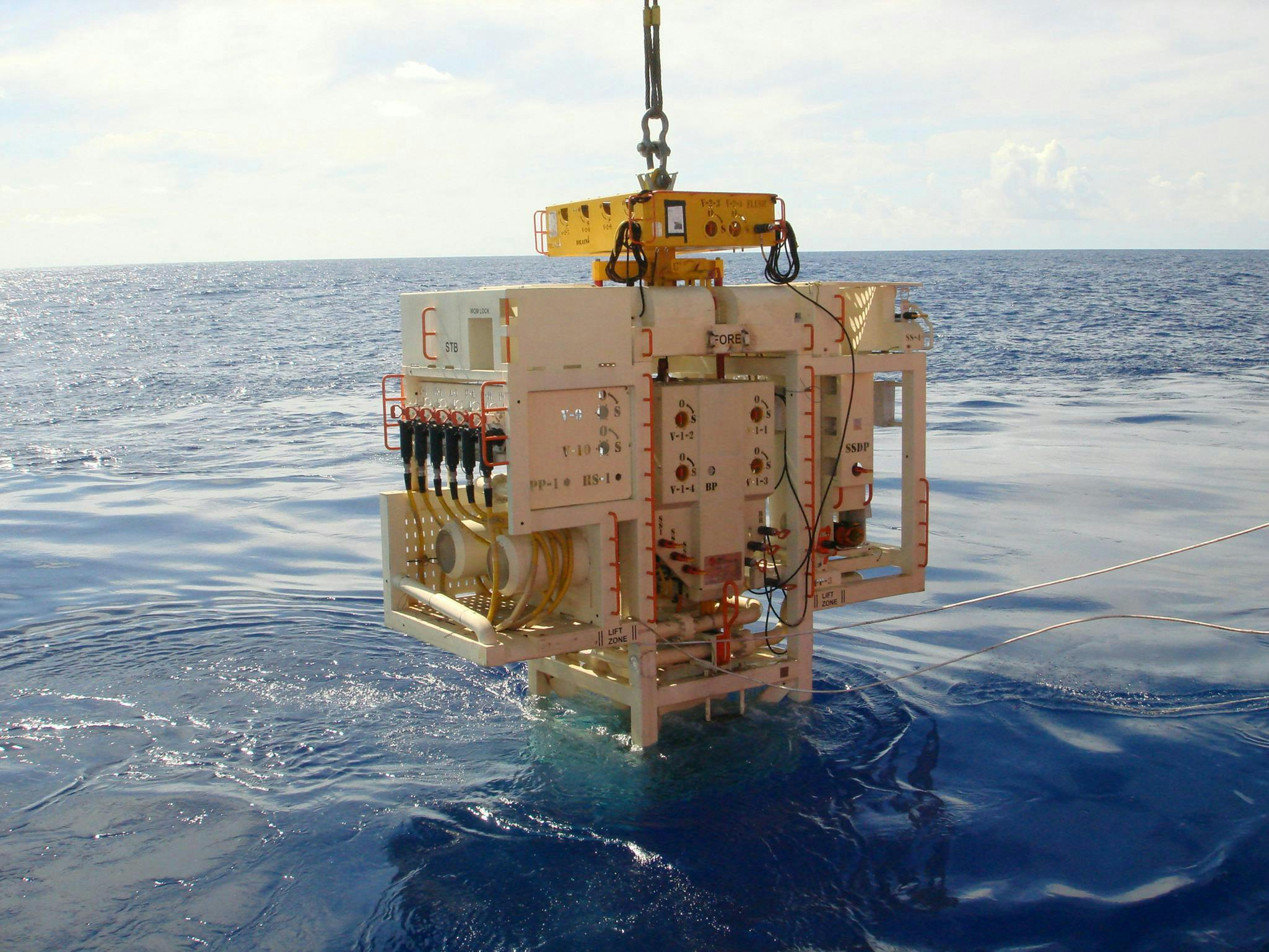

Each OneSubsea RWI system comprises a subsea seawater injection pump on the seabed to draw in seawater, perform coarse filtration and inject it into the reservoir at pressure; umbilical and power controls tied back to an FPSO; and a topside footprint that is reduced to a minimum. OneSubsea’s Subsea Live data-driven performance service provides continuous digital monitoring.

By relocating key treatment and pumping functions to the seabed, the system significantly reduces topside weight and footprint. In practice, about 75% of the physical infrastructure is now subsea, compared to traditional systems where most equipment is located topside.

The suitability of RWI depends on the characteristics of the individual reservoir. At Buzios, compatibility assessments determined that coarse filtration was sufficient for the field’s needs. In fields where sulfate removal or finer filtration is necessary to prevent scaling or souring, more complex solutions (e.g., subsea desulfation water injection modules) are being developed and rolled out.

Drivers for subsea solutions

At Buzios, like many other maturing fields, significant upside oil potential was deemed recoverable if reservoir pressure could be further boosted. Addressing the problem has triggered a change in mindset across deepwater operations in Brazil. Instead of retrofitting FPSOs with new topside injection modules, operators are turning to subsea systems as a direct answer to topside space and power bottlenecks.

By removing the need for large, energy-intensive surface treatment and pumping facilities, FPSO capacity is made available for other critical functions.

Locating injection pumps on the seabed also improves hydraulic efficiency, as water is injected closer to the reservoir, less work is required to meet the injection pressure, reducing frictional losses in long flowlines. This translates into operational cost savings and also lower greenhouse-gas emissions per barrel produced. While the absolute level of emissions reduction varies across basins, the industry estimates show typical energy savings of 10% to 25% that are achievable in deep waters through increased energy and production efficiency.

Implementation challenges and solutions

The real-estate challenge is acute in Brazil’s deepwater FPSO fleet. OneSubsea’s technology included modular, compact topside components tailored to the specific space and power capacity available on two of Petrobras’ units. Across some international projects, creative solutions (e.g., external “balconies” to house equipment) have been added to FPSO designs. At Buzios, though, the subsea-first approach for RWI has avoided the need for expensive or disruptive topside modifications.

OneSubsea’s RWI systems at Buzios are engineered for longer intervals between system refits or filter changes. Digital condition monitoring via the Subsea Live service enables predictive maintenance and rapid anomaly response. OneSubsea’s approach is designed to emphasize standardization and simplification, reduce operational complexity and increase efficiency compared to conventional topside-based systems.

Operating expenditure for subsea water injection is dominated by power costs, which are comparable to those of surface systems on a per-barrel basis. However, improved reliability and reduced routine maintenance can yield marginal opex savings over the system’s life, in addition to the capex advantages of avoiding major FPSO modifications.

A key feature of the Buzios deployment is its integrated digital monitoring and control, built on OneSubsea’s subsea equipment. AI-enabled services provide continuous condition monitoring, enabling early detection of performance fluctuations and better asset management. As the industry builds more sophisticated predictive analytics and AI-driven workflows, even greater improvements in reliability and asset longevity are anticipated going forward.

Broader implications of subsea processing

The Buzios RWI project has provided a platform for the rejuvenation of subsea processing in Brazil. By deploying the right subsea equipment on the right fields, operators can address reservoir management challenges that were previously limited by topside constraints.

While RWI is not universally appropriate, or indeed necessary, its successful deployment at Buzios demonstrates the potential value created by subsea energy systems as fields mature and operational flexibility takes on new levels of importance.

In conclusion, subsea RWI systems have demonstrated at Buzios that they offer operators a means of managing the convergence of challenges: maturing reservoirs, growing topside constraints and intensifying cost pressures. The project also shows the importance of adaptive engineering approaches, digital toolkits and the courage to challenge traditional ways of working to enhance recovery and boost operational efficiency. As technologies evolve, they will have an increasing role to play in extending the life of both operating assets and the fields they serve.

About the Author

John MacLeod

John MacLeod is SLB OneSubsea's vice president (VP) of marketing and technology. He leads the strategy, technology development and communication functions at SLB OneSubsea. In previous roles, he served as VP of business development for Aker Solutions’ Subsea subsidiary. His career in subsea began 35 years ago, spanning many strategic roles, including CTO.

He holds an MSc and BSc in engineering from the University of Strathclyde.