Electrical submersible pumping on seabed allows production bypass

New subsea boosting approach

Roberto Rodrigues

Robson Soares Jr

João Siqueira de Matos

Carlos Alberto Giacomin Pereira

Geraldo Spinelli Ribeiro

Petrobras

Petrobras has pioneered a prototype subsea boosting electrical submersible pump (ESP) on the seabed that allows production bypass and pump retrieval without the removal of the christmas tree and the associated well completion.

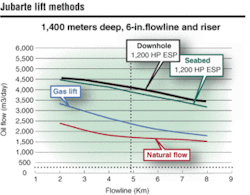

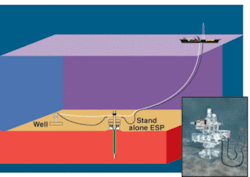

The ESP will be incorporated into a purpose-built subsea capsule, designed for installation adjacent to the christmas tree in 1,400 m of water in the Jubarte field phase 1 development offshore Brazil. A rig will be used for the first installation, but subsequent running and retrieval operations will be performed by cable using a low-cost vessel in 15 production wells in the Jubarte field.

Producing heavy oil

The company has identified large potential reserves of heavy oil offshore Brazil in deepwater and ultra-deepwater. Producing heavy oil in deepwater is a challenge to operators worldwide. To overcome this challenge, Petrobras created a research program called PROPES (Offshore Heavy Oil Program). The objective of PROPES is to develop new technologies to make offshore production of heavy oil fields feasible. Among the projects in the portfolio is the prototype test of heavy oil pumping downstream of the wet christmas tree (WCT) at the Jubarte field.

Petrobras is one of the pioneers in electrical subsea pumping in offshore applications. It installed the first wet completion application ESP in 1994 in the RJS-221 well.. Since then, however, the number of new ESPs Petrobras installed has been modest. Other operators such as CNOOC, Statoil and Total, on the other hand, have been using ESPs more extensively. ESPs have been employed, on the Lihua in the Pearl River Mouth basin and the Lufeng field in the South China Sea, as well as on the Otter field in the northern North Sea.Recent heavy oil discoveries in deepwater and the need to produce marginal fields are making the ESP an attractive alternative in field development plans.

Although ESPs can provide higher potential production, their reported failure rate in the company is about two years (this number includes onshore and offshore dry completion installations).

In the event of an occasional failure of an ESP installed offshore inside a well, an expensive rig would be required to perform a heavy intervention. Present utilization rates indicate that it would be unlikely for a suitable rig to be immediately available. And the time required for the intervention impacts the cash flow because of lost production.

Investigating solutions

In 2001, PROPES began investigating alternatives to minimize production losses and the high intervention costs associated with ESP failure. The proposed solution for maintaining production while awaiting the availability of a workover rig was a back-up gas lift system. Engineers suggested installing the ESP outside the well to reduce the intervention time and cost and to make both installation and recovery easier; in this case, a by-pass system would allow the redundant production with gas lift.

The externally installed pumps are usually integrated in modules and structures to facilitate installation and handling. These pumping modules can be integrated to the WCT/PAB (Production Adapter Base), on a structural base (skid), inside a hollow pile, or even on a pile fixed on the seabed.

Gas lift has traditionally been the company’s preferred method of artificial lift in subsea applications, although four ESPs have already been installed inside subsea wells. Another three ESPs will be installed in the same configuration over the next two years.

VASPS project

The first company application of an ESP outside the production well was the vertical annular separation and pumping system (VASPS) prototype, installed in the Marimba field in Campos basin where the company integrated the pump with a gas-liquid separator in a dummy well. The system was the result of a joint industry project among Petrobras, Eni-Agip, and Exxon-Mobil Corp. The partners built and installed the prototype at the Marimba field in 395 m of water. Production with the VASPS prototype started in July 2001 with a liquid flow rate increase of 30% above the previous liquid flow rate of the well.

The partners installed the VASPS prototype on the seabed at about 90 m water depth. At the separator liquid outlet, an ESP pumps the oil-water mixture at water depths to 1,000 m and at pressures up to 1,000 psi. The separator body is 72-m long and 26 in. diameter, with the pump inside. A rig is required to retrieve the ESP for maintenance, but a by-pass system that uses back-up gas lift in the case of pump failure allows production while waiting on the workover rig.

The innovative prototype configuration is the company’s third ESP application outside the production well. This arrangement retains the productivity advantages of the ESP concept, with the added benefit associated with lower intervention costs.

Extended well test

The second application with the ESP installed outside the production well was in the extended well test (EWT) on the Jubarte oil field. Jubarte, discovered in 2001, lies in the Campos basin about 70 km offshore Espírito Santo in 1,400 m of water Reserves at Jubarte are 17° API oil.

During the evaluation phase, a study based on the of value of information to be collected supported the decision to drill a horizontal appraisal well. In February 2002, Petrobras drilled the ESS-110HP well with a horizontal length of 1,070 m and completed it with an openhole gravel pack. The result of this was a well productivity index 13 times higher than the one the company obtained for the vertical well. It proposed an EWT which allowed complementary valuable information to be collected.

During the EWT, the company used theSeillean FPSO, a dynamic positioning vessel with a rig capable of performing light workover operations. A 6-in. drill pipe riser connected the well to the FPSO. Using an innovative solution, Petrobras installed a 900 hp and 25,000 b/d capacity ESP above the WCT, inside a capsule at the riser string. In case of an ESP failure, it would be needed to recover the drill pipe riser, but the FPSO would be capable of performing the intervention.

EWT production started in October 2002. The well produced by natural flow for two months at a stabilized rate of 16,500 b/d with a constant bottom hole pressure. In December 2002, the company turned on the ESP, and the flow rate increased to 22,000 b/d. The constraints of the FPSO’s processing plant set this upper limit. Petrobras is using the results of the EWT to optimize the development of the Jubarte field.

Possible alternatives

Among the alternative solutions PROPES studied, the first was to install the ESP on the PAB. This solution has many advantages, one of which is that neither a jumper nor a pumping adapter base is required. However, the solution also has disadvantages. The extensive length of the ESP interferes with the running of the BOP during well intervention. Also, good sea floor information is necessary, and it is not possible to use a standard WCT/PAB.

The second alternative was to install a 6-m-high multiphase pump module on a PAB. The main advantage of this solution is the shorter and more compact pump geometry, which makes it easier to handle on the boat during deployment and recovery. This solution was postponed because it is not a totally field proven technology.

A third solution was to install the ESP on a skid base. To make this solution attractive, it was necessary to use two shorter pumping modules (either in series or in parallel) instead of a longer one. Unfortunately, there was not enough time for PROPES to develop a way to avoid doubling all the electric system components.

The fourth alternative was to install an ESP in a hollow pile that allows installation by cable and boat or by drill pipe and rig. PROPES main concern with this solution is how and where to set the ESP inside the module.

In all of the alternatives presented, the pumping module could work vertically or horizontally. There is no data about the influence of the position of the pump on its life span. The best decision should consider the ability to handle the assembly on the surface and during installation.

ESP seabed prototype

Installing the pumping module requires that a hollow pile be set with 37 m in the seabed and 2 m left unburied. The hole would have a 30-in. diameter low-pressure casing and housing.

A pumping adapter base installed on the top of the hole and a pumping module installed on the pumping adapter base make up the support for the system. The pumping module is designed for installation and recovery by cable. The required electric power is 1,200 hp, 4,500 V tension, at 1,400 m water depth.

To reduce risk, a rig with drill pipe executes the first installation. The stack of the pumping adapter base and the module are made on the surface. Later, both are deployed simultaneously reducing rig time. The pumping module can be recovered and reinstalled without killing the production well or deploying a drilling riser or BOP.

PROPES analyzed the seabed installation and determined the ESPs inside the production well have a series of disadvantages besides the high intervention costs. Seabed installation blocks access to the well, requires large holes and casings, imposes conditions on horizontal well geometry, hinders alternative uses, and results in eventual scaling deposition on the pump impellers, which requires inhibitor injection at the pump suction. PROPES concluded that whenever possible, the ESP should be installed outside the subsea well.•

Editor’s note: This is a summary of OTC 17398 paper presented at the 2005 Offshore Technology Conference held in Houston, Texas, May 2-5, 2005.