Configuration, dynamics drive array choices

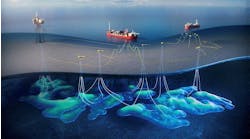

John BeekmanAs the search for hydrocarbons extends into the deeper reaches of the oceans of the world, the need for precision seafloor positioning becomes increasingly essential. Long baseline (LBL) acoustic positioning techniques are being employed to meet seafloor positioning requirements of the deepwater developments currently underway in the Gulf of Mexico.

John E. Chance & Associates

In the early phases of the development of a prospect, a pattern is designed for the placement of the seafloor wells. In some cases, this pattern includes an existing discovery well. The size and geometry of the well pattern is dependent upon the type of production facility to be used.

In 1996, John E. Chance and Associates (Fugro group) undertook the provision of survey support for the batch set phase of pre-drill activities for Chevron's Genesis project in Green Canyon Block 205. Genesis is a joint venture development by Chevron, Exxon, and Fina Petroleum.

The Genesis spar consists of a cylindrical hull with a length of 705 ft and a diameter of 122 ft. Six hundred-fifty feet of the hull is beneath the water line. The hull is capable of supporting production and drilling facilities. A mooring system consisting of 14 anchor piles is connected to the spar by chain and wire which will maintain the hull's position over the well pattern. Genesis is located 150 miles off New Orleans in waters half-a-mile deep.

As the Genesis surface facility was designed as a spar, considerations of the well pattern included the arrangement of well bays in the base of the spar and the dynamics of the production riser systems. The seafloor well pattern consists of 20 wells, two export pipeline riser bases and one ROV guidance pile. An existing delineation well became the initial point for lay out of the pattern.

A rigorous horizontal accuracy specification for the position of each element of the pattern of one foot relative to the target location was required due to the design distances between each well system. To alleviate potential interference problems with adjoining mud mats, an orientation tolerance of ?5°was also specified.

To meet this accuracy, a long baseline (LBL) acoustic positioning system was employed. The major components of the system include intelligent transponders capable of telemetry, sensor monitoring and calculations, an intelligent interrogator mounted on the ROV, an acoustic transducer housed in a towfish and a programmable surface controller. Dual computers running navigation software were used for control, calculation and display of systems information. Using LBL acoustics is beneficial because positioning accuracy is not affected by water depth. Also, each intelligent transponder can simultaneously measure ranges to other transponders, calculate its depth, and acoustically telemeter this information to the surface where a solution for the intersection of the ranges can be computed and displayed. This capability allows real time precise positioning of seafloor structures or mobile targets.

Acoustic array

Prior to drilling activities, a survey/ROV vessel was mobilized to the site to deploy the acoustic system that would provide positioning for the batch set of the Genesis well pattern. A temporary farfield array of intelligent transponders was deployed in flotation collars with weight packages for mooring to the seafloor. The positions of this array were determined using the traditional LBL box-in and baseline measurement calibration methods.Once the farfield calibration was completed, the nearfield array was installed. The nearfield array, consisting of seven 8 ft by 10 ft by 10 ft steel frames with buckets designed to accommodate an intelligent transponder, was deployed. With the transponders installed in the buckets, the frames were lowered to within 10 ft of the seafloor. Using the farfield array tracking the intelligent transponder in the bucket, the vessel was maneuvered to position the frame at its intended location.

Once the frame was within 10 ft of the desired location, it was lowered to the seafloor and the tether to the surface vessel was acoustically released using a heavy duty release transponder. After the installation of all seven frames, a calibration of the nearfield array was carried out. The farfield array transponders were acoustically released and recovered. The nearfield array transponders remained in the frames, awaiting commencement of the drilling operations.

An intelligent transponder was centered on the bore of the existing well for the purpose of determining its true seafloor coordinates. This transponder's simultaneous measurement feature was employed to make multi-range observations to the nearfield array transponders. These measurements were then telemetered to the surface and processed in the navigation software to form a least squares fit position solution. This multi-range positioning method would be applied throughout the remainder of the project. Optimum coordinates for all of the new wells were computed based on the seafloor position of the existing delineation well.

The mobile offshore drilling unit Diamond Winner was mobilized to the site in Green Canyon Block 205. Survey requirements for this portion of the project included accurately positioning nineteen 36-in. diameter by 250-ft long steel casings (batch setting), two pipeline riser base support piles, and an ROV guidance pile.

To facilitate installation of the casings and piles, seafloor targets were employed to provide a visual reference for stabbing the casings into the seafloor. These targets consisted of four synthetic foam floats on rope moored to the bottom with iron clump weights. A 3 ft by 3 ft square pattern was centered on the proposed location of each well or pile. These buoys were placed by the drilling rig's ROV, using an ROV intelligent interrogator for positioning. This interrogator is capable of simultaneously ranging to an array of eight intelligent transponders. This range data is transmitted to the surface through the ROV umbilical and processed in Chance's navigation software for display of the ROV's position.

Included with each 36-in. casing is a mud mat attached about 15 ft below the top of the wellhead. The mud mat is oval in shape and is equipped with transponder buckets at either end of the longest axis. These items were the initial components of the well system installed during the batch set. Prior to lowering, target transponders are placed in the buckets while the mat rested in the rig's moonpool. These transponders are equipped with depth sensors and inclinometers. This assembly is then lowered with the drilling string.

The ROV is stationed near one of the buoy patterns and a casing is lowered to within visual range. The bottom of the casing is then lowered to within 5 ft of the seafloor and held. The positions of the target transponders are used to monitor the small oscillations of the casing. Once the center of motion is determined, the rig's position is adjusted by tensioning on the appropriate anchors. With the center of motion centered over the target, the ROV visually monitors the final lowering and stabbing of the casing. The casing was allowed to penetrate the seafloor soils until self support was achieved. At this time, a preliminary position and orientation of the well system was obtained using the target transponders on the mud mats.

The well system was then jetted down to the desired elevation. During this jetting process, the elevation of the mud mat relative to the known seafloor elevation was monitored with the depth sensors in the target transponders. Once it was determined that the mud mats were in contact with the seafloor, a final position and orientation of the well system was determined. This process was repeated for the remainder of the pattern.

Copyright 1997 Oil & Gas Journal. All Rights Reserved.