Hägglunds Drives supplies hydraulic drives and motors for a wide range of offshore applications. Three recent contracts for subsea intervention, drilling, and pipelay projects illustrate some of its capabilities.

One of those projects was in the UK sector for the winch system for Halliburton Subsea's Toisia Perseus work class ROV, which was designed by Caley Ocean Systems in Glasgow. Halliburton Subsea specified the hydraulic system, drive motors, and power unit based on discussions with Hägglunds. The winch weighs 15 tonnes and can handle 3,000 m of 42 mm umbilical cable at 90 m/min. It is driven by a Hägglunds Viking motor type MK64 11100 with a band-brake assembly and V46C-valve assembly. The drive motor provides a simple drive arrangement that does not require foundations or gearboxes.

Hägglunds supplied a customized Hägglunds power unit for this application with a Spider controller. In this case, the pump was modified to provide extra auxiliary circuits to power and control the A-frame during ROV deployment. The Spider monitors the system and maintains constant power control, enabling fast deployment speeds when the load is buoyant in the water and also ensuring good load management for constant tension wave riding and overboarding duties.

New motors fit old jackups

The company also received a $1.5-million order to upgrade two Baker Marine hydraulic jacking systems in Venezuela. The order was for 36 Viking motors and brakes and included provision of special brake-brackets to allow older motors to be replaced with models from the company's current Viking 84-series.

Baker Marine built more than 40 jackups between 1975 and 1983, each equipped with 12, 15, 18, 24, 36, or 45 pinions, depending on the rig's size, with one Viking motor driving each pinion. Over 1,000 Viking motors were supplied, which made Baker Marine at that time Hägglunds' biggest customer. Since most of these rigs are still in operation around the world, this initial order could be significant, as it involved redesign of the brake brackets. Hägglunds intends to offer a similar service to other owners of aging rigs seeking to modernize their hydraulic jackup systems.

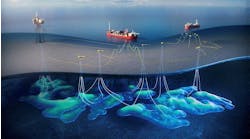

The company continues to find success in the industry through a contract with Rotech Subsea in Aberdeen for its Aquaflow dredging system. The latter generates a high-volume water column that allows excavation of up to 2,500 t/hr of seabed material, without the need for a specialist vessel. The Aquaflow's body is 5.9 m, and the unit is 2 m in diameter. It can be used for numerous offshore applications including pipeline burial and de-burial, seabed leveling or removal for freespan correction on pipelines, and platform decommissioning. It is operable in water depths down to 280 m.

For the system's impellers, Hägglunds provided a drive system incorporating two Compact CA50-25-S motors, fitted with a special seal designed by Rotech. Hägglunds also provided the power unit, with 250 kW installed power and variable flow capacity up to 850 l/min. It is controlled and monitored using Hägglunds' Spider-processor control unit, operator panel, and starter panel.

For more information, contact Ingemar Borg, Hägglunds Drives. Tel: +46 660 870 00, fax: +46 660 871 60, email: ingemar.borg@Hägglunds.com.