New remote concept improves subsea control, long-distance stepouts

The Virtual Control Buoy (VCB) is a new concept for the control of remote subsea gas wells. It uses an Autonomous Underwater Vehicle (AUV) called a seaglider to carry out the control and communication function. This provides a cheaper, more robust means of control than long-distance umbilicals or even control buoys.

“I’ve been in this industry for 17 years, and I think this is the first new thing I’ve seen in subsea controls in all that time,” says Kevin Mullen, an engineering specialist with INTECSEA in Perth, Western Australia. “Yes, we’ve seen all-electric and fiber-optic systems appear, but people were talking about all-electric and fiber optics even 17 years ago. This is something completely new.”

The concept uses a number of proven technologies in a new way that could provide technical and economic benefits for many of the large gas developments off the North West Shelf of Australia, and in some other areas with remote subsea gas.

The concept

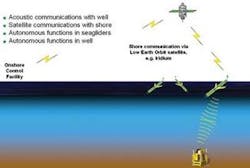

A fleet of two or three seagliders drifts above each subsea wellhead, communicating with the subsea wellhead by acoustics, and with the onshore control facility by Low Earth Orbit (LEO) satellite. Each glider uses GPS to track its position, and if it drifts outside its watch circle, it autonomously submerges and glides underwater, re-emerging on location.

As the umbilical is eliminated, the wellheads would be self-powered using one of numerous technologies proposed and tried over the years.

The mission duration for each seaglider would be 6-12 months, and they could be launched and retrieved from shallow water close to the onshore base, gliding out to the field and returning at the end of mission for maintenance.

Power for the gliders would be generated during dives, using the temperature differential between surface and deep water.

Seagliders

Seagliders are quite different from other AUVs that use propellers or thrusters to move through the water. Seagliders propel themselves by changing buoyancy and by using wings to produce slow and energy-efficient forward motion.

An enabling technology for the VCB is harvesting the energy needed for propulsion from the ocean’s temperature gradient. “It’s not actually perpetual motion, because it uses the temperature difference between the surface and the deepwater,” says Mullen. “It only seems like perpetual motion.”

The result of using thermal propulsion is that the seaglider’s batteries can be used exclusively for control and communication, holding out the promise of longer mission durations.

A pioneer in the use of thermal gliders is Dave Fratantoni of Woods Hole Oceanographic Institution who says, “We now believe the technology is stable enough to be used for science. It is no longer just an engineering prototype.”

Communications

The seaglider communicates acoustically with the subsea wellhead and with the onshore control facility by LEO satellite.

Use of acoustic transmission from seagliders with subsea sensor nodes already is proven.

Acoustic control of subsea wells has already been demonstrated – not from seagliders, but from a platform to the Agip Luna 27 subsea well from 1987 to 1996.

Another enabling technology for the VCB is global low-power satellite networks. LEO satellite links such as Iridium and Globalstar are well suited for the limited data rates.

Because the satellites are in a low orbit, simple low power transmitters are adequate, with antennae that do not require pointing.

The robustness of the satellite network was illustrated on Feb. 10 of this year. The first known collision occurred between two fully intact satellites – Iridium 33 and Russia’s spent Cosmos 2251 communications craft. The hit and run occurred at an altitude of 790 km (491 mi) over the Ukraine, leaving a shower of debris from both satellites. This gave part of the Iridium network occasional outages of up to 10 minutes until Iridium moved one of its eight spares (already in orbit) to replace the lost satellite. The gap was filled within 30 days.

“So the next time you wish upon a falling star, it might just be part of your subsea control system infrastructure burning up in the atmosphere,” says Mullen.

The VCB would be unaffected by this incident, as it would default to a second satellite constellation, e.g. Globalstar.

Autonomous behavior

The VCB concept relies on autonomous operation for the seaglider motions and for well shutdowns.

Position keeping by seagliders is referred to as “virtual mooring,” and it has been demonstrated that a glider can hold station as well as a conventional moored buoy. With two or three seagliders over each wellhead, cooperative behavior is needed between them to ensure that they neither all dive at one time nor drift to the downstream side.

Safe operation of the subsea wellhead relies on being able to close the wellhead when required. Normally this is achieved from the onshore plant via the communication system through the seaglider. If communications fail, the subsea wellhead needs to close in autonomously after, say, 15 minutes without communication from shore.

Other situations such as pipeline rupture need immediate shutdown. This situation can be detected by a pressure sensor at the outlet of the wellhead, with the control system monitoring for a sudden drop in pressure. Generally, this type of shutdown is controlled from onshore or topsides, but for the VCB concept, it should be implemented at the wellhead.

Seabed power generation

Without an umbilical, wellheads must generate their own electrical power and hydraulic pressure to operate valves.

Various concepts (Kvaerner SPARCS, ABB SWAT, and Caltec MURCS) were developed for self-powered wellheads in the ’80s and ’90s. A one-day seminar was held in London in February 1994 on “The subsea future: With or without umbilicals.” Those deliberations were followed in 1995 by the record-breaking Shell Mensa gas field, which at the time was the longest subsea tieback in the world at 99 km (62 mi). In 1996, the East Spar field came into production without an umbilical, using a control buoy connected by radio to the Varanus Island processing facility, 63 km (39 mi) away. The self-powered wellhead seemed to have fallen by the wayside. At present, the major manufacturers have mothballed the technology, and only Weatherford is moving it forward with a design for a Subsea Hydraulic Power Unit.

The “proof of concept” is an autonomous control system for a subsea well (SWACS) developed by Agip. It was deployed on the Luna 27 well in the Mediterranean in 1987 at a depth of 180 m (591 ft). The seawater battery used anodes made of commercial magnesium alloys with seawater as the electrolyte. The well was controlled and monitored by an acoustic link from the Luna A platform, 3,700 m (2.3 mi) away from the well.

The technical issues

Technical issues associated with this concept include problems of seaglider buoyancy, steering and dynamics, and communications. The majority of these issues (and the hardest problems) already are identified, solved by the oceanographic community, academic researchers, and seaglider manufacturers, and those solutions are proven in use over several years.

Remaining problems such as mission duration and battery limits undoubtedly can be resolved. “It’s worth noting that seagliders attract intense interest from the academic community,” says Mullen. “In fact, I’ve got a research student at the University of Western Australia who is working out the maximum mission duration for me right now.”

Reliability

Crucial to any subsea development is equipment reliability. The availability of the VCB and the autonomous wellheads is expected to be as high or higher than technologies such as umbilicals or control buoys. Importantly, in a worst case scenario the expected downtime in the event of catastrophic failure of a seaglider is negligible compared to the loss of an umbilical or control buoy.

The VCB does not have a single point of failure (such as trawling of the umbilical, or sinking, or fire on a control buoy). The distributed nature of control, from multiple seagliders and multiple satellites, makes the system inherently robust and immune to single-point failure. The ability to reassign seagliders from one wellhead to another gives an additional layer of protection, and more seagliders can be launched from shore to make up for any failures.

Back-up control can be implemented easily using an acoustic transponder put over the side of a vessel on the surface, in order to bypass the satellite/seaglider system. It would be similar to the Back-Up Intervention Control System (BUICS) used on Snohvit, but very much simpler, and far easier and quicker to deploy. This technique also could be used during field commissioning and initial start-up.

Seaglider launch and recovery

Seagliders are small, light enough to be handled by two people, and can be launched readily from small vessels in shallow water close to the onshore base, where the sea state is more benign than out in the open ocean. The seaglider sails out to the field, and then returns at the end of the mission for retrieval and maintenance.

VCB concept limits

The concept is not suitable for all applications. Locating the VCB in shipping lanes (or having it travel through shipping lanes on the way to and from the field) is not advisable. Seagliders have been “salvaged” by passing vessels. Areas with ice, constant high currents, or water too shallow for diving, are not suitable for seagliders. Also, the VCB cannot perform chemical injection, annulus venting, or hydrate remediation. Other means have to be provided for these functions.

“In spite of these limitations,” says Mullen, “there are some areas, such as the big gas fields off the North West Shelf of Australia, which are a dream location for the VCB – deepwater, remote, very little infrastructure.”

The next step

Before adopting VCB technology, confidence is needed that the communication and control to critical infrastructure is robust under varying marine conditions, and that adequate back-up is provided to guarantee the required reliability and availability. Initial studies indicate this can be achieved. As with all new technology, considerable work will be needed to fully qualify it.

Mullen says, “I’d like to see this concept tested on a small scale. Think about the Underwater Manifold Centre – Shell tried the technology on the P1 satellite well before building the UMC. But I believe all the technologies for the VCB are proven, the only new thing is using them all together, and using them for control of subsea wellheads.”

“It would be good to get some vendor engagement,” says Steve Rivers, Senior VP at INTECSEA in Perth. “We see our role in this as innovators and system integrators, rather than equipment developers. We are keen to work with the industry, vendors, and operators, to progress this concept from an idea to a fully working solution.”

There are no patents or licenses on the VCB, as this can inhibit development of new technology. The technique is being launched into industry with no strings attached.

Technical issues

Already solved:

- Buoyancy generation

- Hulls and hydrodynamic performance

- Satellite communication

- Local radio communication

- Subsea acoustic communication

- Gliding control

- Scientific payloads

- Moderate construction costs

- Long operational lifetimes

- Near-shore launch and recovery from small boats

- GPS navigation

- Dead reckoning navigation during dives

- Virtual mooring mode

- Reprogramming during mission

- Long distance transits

- In-mission power generation using thermal buoyancy system

Requires further work:

- Fleet behavior, “swarming,” cooperative control

- Energy/power/bandwidth balance