Shallow water workover method moves deeper

Brian Skeels

FMC Technologies

Riserless light well intervention systems are built for today’s shallow water applications, but designs are drawing on North Sea experiences to adapt to tomorrow’s deepwater operations.

Much of the world’s oil supply is no longer in new frontiers. In some areas of the world, such as the North Sea, new discoveries are primarily a thing of the past. This leaves operators with two choices. They can either pack up shop and go somewhere else, or they can find ways to get more from the wells that already are drilled. The latter is made possible with light well intervention technologies.

Riserless light well intervention (RLWI) aims to provide lower cost access to subsea wells. Those wells typically require a workover after approximately five years to ensure peak operating performance. Some operators sidestep the need for workovers in favor of intelligent wells – structures preconfigured with everything needed to perform a well intervention. The theory behind intelligent wells is a good one, but in practice, the problem is dormancy.

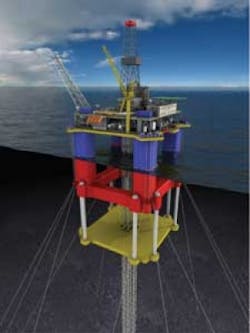

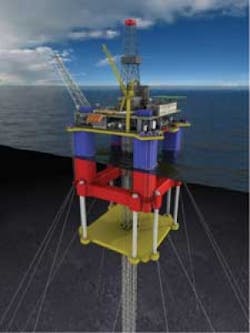

Mark II riserless light well intervention system.

After controls have been dormant inside the well for five years, they often do not work and a workover becomes necessary anyway. RLWI gives the ability to customize the workover to a specific need at half the cost and in half the time of a traditional intervention.

Worldwide there are 1,710 producing subsea rigs more than five years old. That number is expected to reach 2,370 as the world’s fields grow older and produce less. In light of these statistics, FMC Technologies has run two campaigns in the North Sea to prove RLWI’s viability and to evaluate operational and hardware performance.

In 2006, FMC accessed 11 wells in five fields at water depths of 450 ft to 1,000 ft (137 m to 305 m). In 2007, 17 wells in 18 fields were accessed at water depths of 600 ft to 1,300 ft (183 m to 396 m). In 2006, the average intervention time per well was 19 days. This time requirement dropped to 17 days the following year. These intervention times include mobilization and demobilization between wells, crew changes during poor weather, and typically involved running calipers and gauging tools.

Time requirements for intervention also are affected by the use of production logging tools, including leak detection and installation of tubing plugs to isolate intervals with high water content. Adding perforation in new production intervals and installing insert replacement downhole safety valves also was factored in.

Overall oil recovery increased 46% from the 28 wells on which FMC performed RLWI during 2006 and 2007. This is a significant improvement over subsea wells normally left alone because intervention has been uneconomical in the past.

The primary market for this technology is currently the North Sea, where 876 wells are older than five years and thus candidates for a workover. RLWI has been embraced by operators in this region as a practical shallow water workover alternative. Though successful, RLWI continues to evolve as FMC finds ways to recover more from subsea reservoirs and to make the technology more viable for deepwater wells.

RLWI technology

FMC has three RLWI systems performing workovers in the North Sea. One has been working for three years on theIsland Frontier and one each on the Island Wellserver and Island Constructor. All three vessels are operated under a joint alliance between FMC and Island Offshore. The Mark I system installed aboard the Island Frontier includes a stuffing box and pressure control head, a patented flushing/recirculation lubricator, a lubricator disconnect package, a lower riser package, and a connector to the subsea tree.

Key features include subsea flushing to keep well fluid from reaching the surface, a guideline system up to 1,640 ft (500 m), and a lubricator which can contain tool string lengths up to 72 ft (22 m), 7-in bore with 10,000 psi, a hydrate inhibitor system, and a subsea grease injection system.

The Mark II version of the system on theIsland Wellserver and Island Constructor, includes the same features of the first system along with an improved stuffing box, pressure control head, and increased lubricator length to accommodate tool string lengths up to 108 ft (33 m). Eventually, the Frontier will be upgraded to Mark II as well.

A review of the Mark I operating aboard theIsland Frontier pinpointed areas for enhanced performance. One of the biggest challenges with Mark I was dealing with the bulk and weight associated with the closure device atop the lubricator housing. The Mark I lubricator featured a top-heavy wireshear ram cutting device perched atop the 72 ft (22 m) lubricator tube.

The Mark I assembly weighs 10 metric tons (11 tons), and has to be guided and supported on a separate lift line to maintain stability as the lubricator is deployed and operated on the seafloor.

Another obstacle with Mark I was control system architecture. The Mark I installation/workover control system is a discreet-function, direct-hydraulic control system with a surface hydraulic power unit. It has surface chemical and grease injection systems that use a large diameter multi-bore umbilical. This umbilical is cumbersome, and though functional in shallow water, is not well-suited for extended fatigue due to prolonged heave compensation during workover operations. Replacement umbilicals need a long procurement lead time.

FMC now introduces Mark II, building on the experience gained with Mark I intervention technologies. Mark II takes steps toward making RLWI viable in deeper water by reducing weight, optimizing the size of pressure control and closure devices, and upgrading the control system for the next set of vessel deployments.

Mark II makes the heavy lubricator package smaller and lighter plus eliminates the need for guidelines. This, in turn, reduces the number of lines in the water. With less equipment weight, the lubricator length can increase without sacrificing structural stability. The Mark II upper lubricator package includes a compact wireshear cutting ball valve capable of shearing up to 7/16-in braided cable and subsequently sealing the lubricator bore.

The reconfigured pressure control head features a guidelineless re-entry funnel and grease/stuffing box head that is half the height and weight of the Mark I package. The reduction in height and weight and the guidelineless installation makes it easier for am ROV to guide the production control head into position, while the reduction in weight allows the lubricator to stand on its own while in operation.

Mark II also addresses the control system architecture and large umbilical by changing over to a smaller all-electric umbilical combined with a distributed electro-hydraulic control architecture and subsea hydraulic power unit system. The electric power umbilical is common, being used on ROVs worldwide, making sourcing and reliability simple and robust. FMC adopted a distributed electro-hydraulic control system architecture to eliminate the complicated nest of hydraulic lines surrounding subsea hardware and to simplify packaging and access.

The new control system uses a series of smaller control pods, which allows a reliable system to be assembled to operate smaller portions of the well control equipment with more instrumentation. This makes control, monitoring, and diagnosis of the RLWI’s installation/workover control systems easier.

Improvements to the Mark II installation/workover control system go beyond the umbilical and hydraulic control issues. Mark II also improved the grease injection function that limited the working depth of the Mark I system. Conventional practice is to pump excessive amounts of grease from the surface to set a grease injection seal against braided lines.

The amount to be pumped was estimated based on the operating pressure and the rate that the wire line is fed into or out of the well. The grease line practice works in shallow water, but as vessels and jobs move to deeper waters, the length of the grease line makes this more problematic. Injection pressures and rates become questionable and waste grease if over-supplied or resulting in hydrate or well control problems if under-supplied.

For Mark II, FMC developed an electrically controlled, self-monitoring grease injection system that works with the pressure control head to address this problem and to make deepwater operation possible. The new grease injection system uses less grease. That grease is housed in a small reservoir on the pressure control head. Grease is dispensed in precise quantities and rates based on real-time monitoring of wellbore pressure. For extended service, additional grease may be brought down to the Mark II in replacement containers via ROV and plugged into the pressure control head to eliminate the need for a grease line altogether.

RLWI in deeper waters

The last several years of operating RLWI in the North Sea were valuable toward making this technology viable for deeper waters in other regions. Mark II contains many components with a water depth rating of 10,000 ft (3,048 m) and the significant improvements made from Mark I to Mark II all focus on operations in deeper waters.

One issue that remains is the surface vessel. As the Mark II technology becomes customized for deeper waters, winch and umbilical reel sizes must increase. In turn, load capacity requirements must be increased so that in the end, heave compensation equipment power requirements must increase five-fold.

The ever-increasing size of the systems leaves the RLWI vessels taxed for deck space, deck capacity, and facilities power. If the vessels are made larger, day rates and operational costs could increase to match the currents rates of mobile offshore drilling units. If RLWI does not reduce intervention costs compared to mobile offshore drilling units, the economic drive for RLWI disappears.

There are ways to avoid an increase in component size to get an increase in water depth. Take a hard look at the components of RLWI to see if their sizes and weights can be reduced in the way bend-over-braid lifting ropes decreased wireline size and decreased weight. Bend-over-braid lifting ropes and composite cables are neutrally buoyant in seawater, yet have the same tensile strength of steel slickline wire, braided wire cable, or wire rope.

With conventional wire cable or rope, reel and winch capacity diminish with increased water depth as the reel and winch are forced to support the weight of the original payload plus the added weight of the wire rope. The neutrally buoyant nature of bend-over-braid rope does not take away from winch capacity to keep reel capacity and power requirement in check and to reduce the size of these components.

Another hurdle before RLWI can be completely successful in deeper waters is line management. In shallow water, many RLWI operations have seven to nine lines in the water. In deepwater, four lines are removed in the switch to guidelineless operations. The ROV and lighter components allow the remaining lines to perform double duty. For example, the composite cable can perform the functions of the production control head lift line as well as raising and lowering the wireline tool in and out of the well. Fewer lines in the water also mean less heave compensation equipment, further simplifying deepwater RLWI.

Looking forward

RLWI has gained momentum with the growth of subsea completions. Operators have to ask if the market is sufficient to produce returns that justify cost. Do we engineer a generic system that would work in most circumstances or build specific capabilities to the operator’s product?

Regardless, increasing reserve recovery rates through increased low cost/high availability subsea intervention is one initiative with an overall plan to raise recovery rates of existing projects. RLWI is a natural option towards this goal.