Schlumberger announces new mobile PVT lab

William Furlow • Houston

Schlumberger Oilfield Services says its PVT Express wellsite fluid analysis service can deliver reliable fluid property results in as few as eight hours turn-around, processing time.

This mobile system provides pressure-volume-temperature (PVT) fluid analysis using less than 50 ml of fluids. The small volume and quick turnaround enable informed decisions by operators during logging and well-testing operations and eliminate the costs associated with traditional fluid analysis operations.

By comparison, traditional laboratory services are conducted in fixed-location laboratories and take between six and eight weeks to analyze fluid measurements. They also require 200-4,000 ml of fluid.

In a well offshore Newfoundland, the PVT Express system delivered two complete PVT studies within hours of recovering the modular formation dynamics tester (MDT) samples at the surface. These results matched the known PVT properties from the exploratory well, eliminating the requirement for a well test and resulting in earlier economic analysis for completion design and speedier field development.

Mercury-free laboratory equipment and modular, rugged construction allow this system to be fully transportable by land, sea, or air. The PVT Express hardware/software laboratory includes fiber-optic sensors to measure saturation pressure of gas condensates, volatile oils, and black oils. Patented helium ionization detectors are used in dual gas chromatography to perform C12+ gas analysis and C36+ liquid analysis.

Schlumberger says its proprietary PVT Expert software model processes all laboratory measurements and instantly provides the final PVT report. Additionally the PVT Expert software model assesses the reliability of the PVT results to ensure data quality.

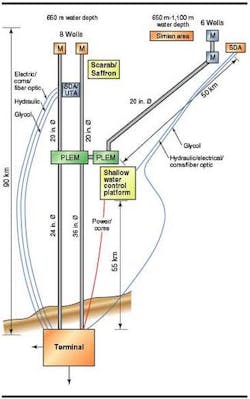

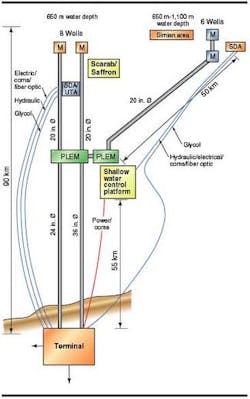

Longest subsea tie-back using large-diameter pipe

Intec is providing engineering for the installation of deepwater seabed facilities feeding a record, 70-mi subsea tieback on the Simian Sienna and Sapphire projects, according to Peter Roberts, Intec's managing director for Europe, Africa, and Middle East operations.

Shell's 68-mi Mensa subsea tieback now holds the distance record. First hydrocarbons from Simian Sienna wells, located in water depths to 3,600 ft, are planned for 3Q 2005, with pipelines from the fields tying into the new Scarab Saffron West Delta Deep Marine subsea system.

The Simian Sienna development concept will include a record-length tieback for deepwater.

Burullus Gas Co. operates the Simian Sienna and Sapphire deepwater projects, north of the Nile Delta in the Mediterranean Sea, on behalf of WDDM concession partners BG and Petronas. Burullus Gas is a joint venture company, comprising Egypt national oil company Egyptian General Petroleum Corp., BG-Egypt, and Petronas.

Production from the Simian Sienna wells, northeast of the Scarab Saffron fields and 71 mi offshore Idku, will provide feedstock for the Egyptian Liquefied Natural Gas (ELNG) export plant in Idku.

The Sapphire field, west of Scarab Saffron and 46 mi from the Nile Delta shoreline, is a separate development, scheduled to tie in to the West Delta Deep system in 2006.

For the offshore facilities, the project management team will manage the engineering, procurement, installation, and commissioning (EPIC) contract. The EPIC package includes all subsea components and the design, fabrication, and installation of a newbuild unmanned controls platform. Intec also is performing detailed flow assurance of the system.

Intec completed a front-end engineering and design study on this project in 2002. As a member of the project management team, Intec was charged with the technical tender evaluation of the EPIC contract and will be responsible for technical assurance aspects of the project, including:

- Six subsea christmas trees

- Two subsea manifolds

- One tie-in manifold

- A 26-in. export pipeline

- A 20-in. in-field pipeline

- Four, 10-in. flowlines from the trees to the manifolds

- Umbilicals

- A subsea control system

- A 4-in. vent pipeline

- A 4-in. glycol pipeline

- A controls platform.

The Sapphire development uses a similar deepwater subsea system, including eight subsea christmas trees.

While this system design uses proven technology, there are several challenges associated with the development, according to Graham Taylor, Intec's project manager for Simian Sienna through the FEED stage. Those challenges include:

- Avoiding hydrates

- Controlling chemical injection in required quantities

- Large-diameter connectors

- High production rate trees: 150 MMcf/d.

The Simian Sienna and Sapphire developments each comprise two production hubs, a 26-in. export pipeline for tie-in to the Scarab Saffron system, and a 20-in. in-field pipeline between two manifolds.

The Simian Sienna and Sapphire pipelines are controlled independently of the Scarab Saffron system, using an electro-hydraulic multiplex system. The controls equipment and a methanol injection unit will be mounted on the controls platform, which will be remotely operated through a combined power and communication umbilical from an onshore facility.

"The controls system represents an industry first because of a combination of length and system complexity," said Taylor.

The 26-in. export pipeline originates at M1 and connects into the Scarab Saffron pipeline end manifold via a tie-in manifold in 312 ft of water, 41 mi from shore.

The Sapphire field calls for an initial development of eight production wells in water depths ranging from 1,168 ft to 1,637 ft, with tiebacks to additional manifolds, each with provision for future manifold tie-ins.

New PRT design for Thunderhorse

This month, Westech will ship a 1,200-kip-capacity production riser system (PRT) to Transocean's Discoverer Enterprise drillship. In November, the new PRT will be placed into service in the BP Thunder Horse field in the Gulf of Mexico.

The PRT will provide 1.2 MMlb of tension over a range of 45 ft. Six long-stroke hydraulic cylinders provide uniform force and redundancy to the 6,300-ft-long riser string. With a maximum diameter of 58 in., this unit preserves valuable rig space, Westech said.

Placing the PRT into service will be simplified by the fact that it is top supported and can land out in the rotary or in a template. The PRT is built to DNV code and designed for use aboard mobile offshore drilling units, FPSOs, spars, and TLPs in water depths to 10,000 ft.