Mitigating deepwater pipeline buckling and axial stability

Amitabh Kumar

Brian M. McShane

INTECSEA, WorleyParsons Group

Increased deepwater development over the last decade, together with industry monitoring of high pressure/high temperature (HP/HT) flowlines, reveals the critical nature of global stability in the management of flowline buckling and axial stability of these systems.

Global stability is one of the most important design considerations for a flowline system. This concern represents the potential for a flowline to move either axially along its length, laterally from its installed condition, or vertically causing flowline upheaval.

Large compressive forces induced on a flowline system once operational causes this phenomenon. Contributing factors to this phenomenon include seabed terrain, boundary conditions, and operating strategy.

With more than 25,000 mi (40,234 km) of pipeline in the Gulf of Mexico alone, global buckling and axial stability of production flowline systems in water depths between 3,000 ft to 10,000 ft (914 m to 3,048 m) presents an industrywide concern for flowline integrity.

Short flowline systems, generally in a range of 3 to 5 mi (4.8 to 8 km) in length, with the complexity of HP/HT conditions, can translate axially or “walk” as a result of normal operational start-up and shut-down.

More recently, however, flowline systems which incorporate wet insulation and which have comparatively low specific gravity also show a high propensity to walk, even for systems 15 to 20 mi (24 to 32 km) long. INTECSEA has completed a case study on these deepwater systems, identifying specific design aspects of wet-insulated flowline axial stability and associated analysis, and suggesting mitigation options.

Flowline/pipeline systems installed on a steeply sloping seabed compound the problems and underscore industry resolve to remedy these issues. Finite element analysis of wet-insulated systems on steep slopes helps quantify the impact of cyclic thermal and pressure loading on a given flowline.

System impacts

The impacts of deepwater buckling and upheaval on deepwater pipelines and flowlines can be significant, including:

- Significant cumulative end expansions greater than 20 ft (6 m) can occur until a system reaches a point of stability

- Flowline system response is characterized by interaction of the seabed slope, flowline expansion, lateral displacement, and effect of the thermal/pressure gradient and thermal cycling

- Selection of a nondirect or somewhat “meandering” flowline route, combined with full-scale, three-dimensional finite element modeling, can mitigate significant end expansions

- Most favorable routing for a deepwater flowline system design may challenge developers, as some seabed features are not avoided easily and can impose significant cost increases on a project

- Flow assurance performance requires that many flowline systems have good thermal properties, or low U-value; i.e., overall heat transfer coefficient. Thermal insulation applied on the outside of the flowline can facilitate this performance

- A common system configuration uses wet insulation applied on the outside of the flowline and exposed to the marine environment. A single or multilayer coating system of five to seven layers is common

- Low specific gravities of systems can result in a low flowline submerged weight and, consequently, low axial frictional resistance

- Project terrain combined with low system-specific gravity, and typical production temperature and pressure conditions makes the flowline system susceptible to global lateral buckling as well as axial creep.

The INTECSEA case study addresses these, given the following flowline parameters and conditions: A wet-insulated production flowline system (D/t~17, inlet temperature = 200° F/93º C ) routed across an area of steep slope with a product-filled specific gravity of 1.5 and approximately 20 mi ) in length.

Problem overview

The industry has several deepwater flowline systems routed across challenging seabed features with seabed slopes ranging from 5º to approximately 40º. Notable projects that have negotiated such features include:

- BP’s Atlantis project over the Sigsbee Escarpment in the Gulf of Mexico

- Norske Shell’s Ormen Lange project over the outer continental shelf in the North Sea

- Medgaz – developed by a five-company consortium – across the Mediterranean Sea from Africa to Europe

- Gazprom/Eni Blue Stream across the Black Sea.

Low-pressure and low-temperature flowlines or export pipelines are comparatively easy to manage because of lower axial force.

A long HP/HT flowline system – fully restrained axially rather than a short flowline – experiences end-expansion and potential for high stresses resulting from lateral displacement at natural seabed features.

In contrast, a partially restrained system – where available seabed friction resistance is not sufficient to balance the compressive force in the flowline – encounters design complexities. Aspects of this system include large transient cumulative expansion and a propensity for the entire system to translate gradually from one end – hot or cold – to the other end – hot or cold – after each cool-down/restart cycle, causing the walking phenomenon.

While walking normally is associated with short flowlines, wet insulated systems ranging up to 20 mi (32 km) long also have these issues. This primarily results from lateral buckles – engineered or natural response – that separate flowline response on either end. In effect, the flowline behaves like a partially restrained system similar to a short flowline.

Analysis of such a system on a flat seabed – including effects of sloped seabed or riser-bottom tension – is a common design approach to quantify flowline walking behavior. Modeling provides a time-efficient solution convergence and reduced computation time and cost.

Limitations to such modeling techniques, however, include seabed undulations, potential flowline spans, irregular bathymetry, and narrow opportunities to identify true flowline response. Selection of the most appropriate design and mitigation requirements is thus limited as well.

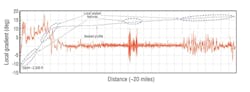

For the case study operating conditions, the system is prone to lateral buckling because the compressive force of the flowline is higher than the critical buckling initiation force. The associated flowline route topography is a typical seabed phenomenon in deepwater areas with average gradients ranging from 5º to 10º over a distance of 1 to 3 mi (1.6 to 4.8 km).

Designers can apply a staged approach to assess flowline parameters, with the initial step taking an analytical solution. An initial finite element analysis using two-dimensional finite element modeling, followed with detailed three-dimensional finite element modeling of the actual flowline route, is preferred.

Flowline analysis finite element software (ANSYS) follows in a sequence of load steps, beginning with an as-laid or empty condition and proceeding toward flooded, hydrotest, and operating conditions. The computed analysis includes seabed and flowline profiles, spans, stresses/strains, axial forces, and flowline displacements.

In the case study, water depth ranged between 200 ft (61 m) at the shallow end and 2,500 ft (762 m) on the deep end. The route also had three curves along its length. The average seabed gradient was approximately 8º to 10º across a 3-mi (4.8 km) slope, with the maximum gradient of approximately 20º near the top of the slope.

Preliminary analysis

The analytical solution shows end expansions of 25 ft and 16 ft (7.6 m and 4.9 m) on hot and cold ends, respectively. The two-dimensional analysis shows end expansion of 12 ft and 3 ft (3.65 m and 0.9 m) on hot and cold ends, respectively. The two-dimensional analysis shows that uncontrolled lateral displacement would overstress the pipeline.

Following these preliminary assessments, with its own limitations on predicting the true flowline response, INTECSEA created a full three-dimensional finite element model that includes pipeline route bathymetry and route curves.

This model provides improved global and local predictions of flowline response and associated stresses, expansions. The model also includes pipeline route lay radii, or curves, ranging from 5,000 to 8,000 ft (1,524 to 2,438 m).

More realistic predictions for end displacements are approximately 6 ft and 3 ft (1.8 m and 0.9 m) at the hot and cold ends. Hot-end expansion, compared to two-dimensional assessments, is nearly 50% lower, whereas the cold-end expansion remains more or less unchanged.

Axial force reductions from the previous analysis result from more locations or instances of lateral flowline displacements. This analysis shows a maximum lateral displacement of approximately 40 ft (12 m). These lateral displacements are acceptable because the flowline is not near seabed features that would contribute to its lateral instability.

Reduced stress levels at the displaced flowline sections were confirmed with a local buckling check, per DNV-OS-F101. The local buckling unity check along the entire flowline length was within the acceptable limit.

Seabed intervention

To evaluate the impact of engineered initiation sites for lateral displacement, INTECSEA included simulated sleepers, or pre-laid pipes, which facilitate flowline displacement. End displacements are 6 ft at hot end and 3 ft at cold end, as predicted by the 3D assessment without pre-installed initiation sites.

The study examined the axial force and lateral displacement along the flowline length. The artificial displacement units induce the flowline to displace at 15 locations; 11 of them similar to the natural displacement locations seen in the previous analysis. These displacements indicate pre-installed sites are not required as long as the flowline displaces naturally.

In some instances, however, intervention systems may be installed to facilitate expected flowline response, as non-engineered lateral displacement may overstress the flowline. A maximum lateral displacement of approximately 35 ft (10.6 m) is observed, and maximum lateral displacements within 5 mi (8 km) from the hot end range from 25 to 30 ft (7.6 to 9 m).

Transient finite element simulations focus on flowline cumulative expansion and whether the entire flowline system would translate independently on both ends, hot or cold.

INTECSEA created an ideal, or best-option, temperature profile for the transient heating cycle and cooled the flowline system uniformly along its length. During cool-down, the effective axial force changed direction from compressive to tensile on a partially restrained system. A component of lay tension also may be included in the effective force.

Transient cycling assessment

The transient cycling assessment captures the transient response when the flowline displaces at specified locations and is especially critical within 3 mi (4.8 km) of either end. Importantly, the assessment shows that seabed intervention improves the overall expansion, which reduces significantly during the transient cycling stage. Controlled flowline displacement at pre-installed and natural seabed locations facilitates this improvement.

Transient thermal cycling analysis of the flowline system illustrates that if the flowline displaces naturally at crucial seabed features, the initial flowline response is dominated by transient cumulative expansion. During this condition, both ends of the flowline expand independently and increase overall end expansions. A steeply sloping seabed – a contributing component of this phenomenon – inherently causes the flowline to move down-slope, with gravity imposing tension to a hanging flowline.

This tension becomes increasingly critical if the hot end of the flowline terminates near the bottom of the slope. The flowline length resting on the slope also contributes to the slope of axial force distribution. For this case, flowline expansion more than doubles after only three transient cycles.

Expansions escalate in part because the thermal gradient of heating cycles does not create enough force to displace the flowline; whereas during static full operating condition, thermal gradient displaces the flowline naturally. Heating cycles, therefore, push the flowline axially on either end.

Because high end expansions—both static and transient—are not a favorable design solution, displacement units along the flowline at specified seabed locations facilitate optimum system performance.

If the behavior of the full 3D assessment, including route curves, responds to transient cycles in the similar order of magnitude, final hot end expansion can range from 8 to 9 ft, which is 30% to 50% higher than the predicted 6 ft. The cold end expansion will increase to nearly 6 ft.

Study of axial force and lateral displacement along the flowline length showed a maximum lateral displacement of approximately 35 ft.

Both these values are within feasible range for design of end tie-in spools and can be reduced, based on specific design considerations, in consultation with operators. Ideally, a design strategy calls for keeping expansion below 6 ft for most flowlines. End expansions that exceed this goal may require sliding end mechanisms and/or anchoring.

A large component of this transient expansion is accumulated during the first two to three cool-down/heat-up cycles. Subsequent transient expansion gradually tapers to a net relative expansion of zero. At this point, the flowline system effectively exists in a quasi-static zone with the system either stabilizing – indicating no further expansion and axial creep – or transitioning to an axial creep or walking zone.

Based on results of this assessment and engineering judgments from related sensitivity work, the flowline system tends to expand independently during transient temperature cycling and then ceases to expand on both ends after seven to eight full cycles.

Following this stage, the flowline shows signs of stabilization. This study, however, did not eliminate the possibility of axial-creep/walking of the system, because results depended on numerous factors, and are an integral part of such behavior.

The study also suggests that if displacement of a flowline is controlled on or near the slope, designers can further reduce overall cumulative expansion and eliminate axial-creep by optimizing the size and location of an artificial displacement unit. Importantly, the study shows flowline system feasibility and that with adequate measures, designers can achieve lateral buckling integrity of the overall system and end tie-in structures.

Recommendations

INTECSEA’s assessment of design issues associated with wet-insulated HP/HT flowline systems on a steep slope include:

- Simplified end expansion analysis of these systems can be very conservative and can indicate that a configuration is unfeasible. In some cases, even two-dimensional assessment may not provide true response of the flowline. To accurately assess the response of such system, a complete set of 3D assessments is necessary.

- For a given operating condition, wet insulated HP/HT flowlines—even as long as 20 mi (32 km) — may be susceptible to a large cumulative expansion due to a series of transient; i.e., start-up/cool down, events. Most flowline systems reach the maximum cumulative expansion after two heating cycles. A wet-insulated system on a slope, however, may require five to 10 heating cycles to achieve the maximum cumulative expansion; i.e., stabilizes. This process, though, results in very high end expansions of 10 to 20 ft. The ability to mitigate the cumulative end expansion is critical to a feasible design solution.

- The potential for flowline walking is a central design issue for a HP/HT wet insulated flowline. Designers, however, can mitigate this phenomenon using 3D modeling to generate effective routing of the flowline and to optimize seabed intervention.

Flowline projects that incorporate wet insulation on steep seabed terrain should perform both a design assessment and significant sensitivity reviews of all the relevant parameters. The overall solution is dependent on the flowline system moving with a predictable response, confirmed by analyses. Sensitivity assessments should include: laying pipe within the lay corridor but not on the design centerline; variability of soil conditions; variability of lay radius; and other known flowline conditions and engineering impacts.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com