Aker Kvaerner sees increased potential for integrated operations

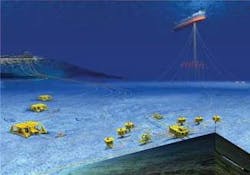

Subsea integrated operations (IO) offer rich potential in terms of improved oil recovery and reduced operating costs, says Aker Kvaerner Subsea. The company is implementing a detailed strategy for subsea IO and also is involved in Statoil’s Tail Integrated Operations project.

The strategy was derived partly following an in-house assessment of Aker Kvaerner Subsea’s capabilities and defining e-field products, and also an external analysis of competitors and the market in general. There also were interviews with operators, who responded positively to the company’s proposals, says chief engineer Kristin Falk.

The emergence of high-speed subsea data networks, improved subsea and well instrumentation, subsea power supply and instrumentation, the acceptance of subsea boosting, and the first subsea processing projects, all provide the technological foundation for subsea IO, Falk says.

Aker Kvaerner Subsea sees such operations developing at four levels:

- Monitoring of equipment and operations in real-time

- Analysis of data virtually in real-time to provide useful information

- Optimization - real-time intervention to optimize operations

- Remote operations - innovative ways of working.

The company sees its role as a system integrator. While it is a supplier of some subsea tools, it also is experienced in building systems incorporating its own and third-party products, and in working with other suppliers to facilitate integration of their products into systems.

Statoil’s Tail Integrated Operations is a three-year R&D project aimed at developing technology for use in IO. One of the topics being addressed by Aker Kvaerner Subsea is the reliability of subsea equipment. Failures in downhole sensors or in the communication system can seriously impact production. While equipment which fails may simply have to be replaced, a malfunction in the control system, for example, may be reparable remotely.

Another area the company focuses on within the project is condition and performance monitoring - developing systems, methods, and a maintenance philosophy for subsea equipment. For example, accurate models for early fault detection and instrument drift allow the operator to respond to a problem before it fully materializes. Such an approach clearly is preferable to the current philosophy, which usually is to take no action until a failure occurs.

“Aker Kvaerner Subsea has a high focus on condition and performance monitoring of our subsea pumps,” says Falk. Both the multiphase booster pumps it supplies BP King and the recently awarded Tyrihans water injection pumps for Statoil, will have condition-based monitoring systems. The CNR Lyell multiphase booster pump, delivered last year, is operating with vibration sensors. “Thanks to new technology and the use of integrated operations, it is possible to monitor the pumps from land, including for maintenance and replacement,” Statoil said of the Tyrihans contract.

The company also proposes online rate estimation tools based on existing instrumentation. This tool combines flow models of the production network and measurements from sensors to estimate the rates from individual wells and production zones. Such systems also can backup existing sensors, as flow values can be computed from the network model and remaining sensors even if some sensors fail. This kind of solution is sometimes referred to as a “virtual multiphase meter”.

Moving up another step, the same software used to build systems such as a virtual multiphase meter also can be developed for production optimization, using data and information from the whole production system to calculate the choke settings for the wells, gas lift, chemical injection flows, pipeline flow rates, and so on to optimize production.

A field simulator is another key tool based on similar models to a virtual multiphase meter. This would examine what-if scenarios - how much would production be improved by an increase in gas-lift, or which wells would benefit if a pump were installed at this or that location? The field simulator could be combined with a reservoir simulator for a life-of-field perspective.

To link the customer more closely to the supplier, Aker Kvaerner Subsea proposes a mySubsea function. This would include, for example, a link to monitor information on equipment reliability, and a live video link to the supplier’s workshops to keep the customer updated on the progress of repairs. The company has established this function as part of its subsea maintenance contract with Shell.

If subsea IO is to progress, customers and suppliers have to rethink their relationship, says Falk. Suppliers need an incentive, such as performance related rewards, to supply a more efficient service - rather than selling the customer a pump, they need to sell pump uptime. And if they are to be involved in monitoring the pump performance, they need access to performance data and the opportunity to respond when performance deviates from the norm.

Customers also need to re-examine their attitudes. If they are too risk-averse, they may miss the full benefits of production optimization by refusing to run maximum production because it might entail higher risk of failure. Falk’s vision is to have a software suite to support the operator in the decision-making process to ensure optimal production and cost-effective solutions by, for example, quantifying the degree of risk in running maximum production.