Overcoming difficult thermal challenges in deeper waters

Ziya Atakan, Mentor Subsea Technology Services

Oil and gas subsea field developments in deeper waters face various technical challenges as a result of the more hostile environmental conditions. Overcoming these challenges requires a combination of careful and innovative design, and extensive and tightly controlled multi-phase flow assurance operational strategies and procedures.

Design of subsea systems begins with fluid characterization followed by establishment of a field architecture and development of economical flowline configurations consistent with safety and minimum intervention requirements. Understanding and designing for the thermal behavior of the system can lead to minimum intervention and least production loss.

The basic challenges of deepwater can be divided into two categories:

• Challenges to overcome for normal (steady state) operations

• Challenges to overcome for dynamic (transient) operations.

The performance goal for steady state operations is to achieve platform arrival temperatures above hydrate formation temperature and/or wax appearance temperature (WAT) as a minimum. The performance goal for transient, i.e. shut-in, operations is to achieve adequate cool-down time before the pipe contents cool to the hydrate formation temperature after shut-in. Besides shut-in, depressurization and wax removal come into play as other major transient challenges in deeper waters.

One method used to overcome both steady state and dynamic operational challenges is to insulate the production system appropriately. The basic challenges are extreme water depths, large external ambient pressures and cold seawater temperatures.

Extreme water depths may not allow the system’s pressure to be reduced below hydrate-prone conditions. The large external pressures are due to the hydrostatic pressure of the water at the sea floor, where the subsea production facilities are located. In most cases, the large external pressure does not allow the use of certain easily compressible insulation materials without providing a strong external shield (jacket). These insulation systems are called pipe-in-pipe configurations. Typical wet insulation materials that can be applied directly onto the carrier pipe include neoprene, carazite, polypropylene, syntactic polyurethane, polybrid, and Eccotherm tape, all of which have water depth limitations.

In general, the materials with the best insulation properties, i.e. low thermal conductivity, also have low density and low compressive strength. There are currently no low density insulation systems that do not require an outer steel jacket pipe to resist the external hydrostatic pressure and installation loads. These materials are generally closed cell micro-porous materials. The most common closed cell micro-porous insulation material for pipe-in-pipe systems is low density polyurethane foam (LDPUF), which has an outstanding thermal insulation value (0.0156 Btu/ft.hr.°F @ 3.746 lb/ cu ft or 0.027 W/m.K @ 60 kg/cu m) but minimal compressive strength. Other closed cell micro-porous materials include silica or cotton based blanket, calcium based powder, and glass.

The thermal performance of subsea production flowlines is measured by the overall heat transfer coefficient value (U-value): the lower the U-value, the better the thermal performance. Lower U-values require a larger annulus between the jacket and carrier pipes, i.e. thicker insulation. However, a deeper depth rating requires a larger jacket pipe wall thickness, which decreases the annulus size. Figure 1 presents the maximum depth as a function of U-value for a 6-in. nominal carrier pipe and varying jacket pipe size. The insulation material considered here is LDPUF.

For long distance deepwater subsea tie-backs, even the closed cell micro-porous materials may not be adequate to overcome low ambient temperatures to achieve required arrival temperature. To improve thermal performance, reduced pressure together with a micro-porous material can be used in the annulus of pipe-in-pipe systems. These systems provide ultra-low thermal conductivities.

Use of reduced pressure in the annulus of pipe-in-pipe systems, however, adds extra cost to the overall economy of the field development project (the capex phase). Such insulation systems can combine excellent U-values with extended long cool-down times. The performance by such systems is an improvement of an order of magnitude over conventional pipe-in-pipe designs.

Electrical heating and pipe-in-pipe hot liquid circulation systems (which require dual lines) are also available with certain limitations, which in addition to high capex, also add opex to the overall cost of field development.

Pipeline burial is used as another means of providing thermal insulation to the production flowlines to certain water depths. The thermal conductivity of mud may vary between 0.38 Btu/ft.hr.°F and 1.20 Btu/ft.hr.°F, which is high compared to other wet insulation materials. While not as effective as pipe-in-pipe insulation in achieving low U-values, burial may be a very cost effective insulation in limited water depths. Two concerns arise with flowline burial, namely warm up times from a cold start up and flowline buckling.

The use of a thick layer of a moderately poor insulator means that substantial time may be necessary to establish a steady state temperature profile through the insulating material. This would also require large chemical (methanol or equivalent) injection volumes due to prolonged duration of warm up above hydrate formation temperature. Thus, the potential increase in opex must be weighed against any capex savings. Temperature changes and thermal growth of the flowline must also be considered, as burial will restrain the flowline from free expansion and may cause upheaval buckling.

The temperature drop of the fluids in shallow water flowline/riser multi-phase production systems is dictated by two factors:

• Temperature drop due to heat loss to ambient.

• Temperature drop due to change in pressure at constant enthalpy.

In addition, the temperature drop due to gas expansion resulting from potential energy loss as the fluids are conveyed from the riser base to the topside’s facilities can be listed among deepwater thermal challenges. In shallow water, there have always been potential energy losses, but the losses were never consequential enough to affect flow rates.

Potential energy losses are directly proportional to water depth. Although these losses can be ignored for shallow-water applications, in deepwater the elevational changes are significant. Therefore, this temperature drop becomes a consideration that must be taken into account.

If this additional temperature drop becomes significant enough, then improvement on the flowline insulation, rather than riser insulation, must be considered. The heat preserved in the flowline can be used in the riser to meet the arrival temperature specification. Alternatively, subsea artificial pressure boosting can be used to elevate the pressure of the system or else the riser should be actively heated.

Of these options, additional flowline insulation is generally the most economical solution. Subsea artificial pressure boosting requires additional subsea equipment/pipework with scheduled maintenance and topside choking to meet separator pressure specification. Active heating will also require additional equipment and pipework, as well as increased opex and maintenance work.

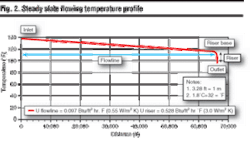

Fig. 2 presents a case for a water depth of 4,600 ft (1,400 m) where a U-value of 0.097 Btu/ft2.hr.°F (0.55 W/sq m.K) relative to pipe internal diameter had to be used for the flowline to overcome additional heat loss due to gas expansion through the riser. When compared, the temperature drop (19.6°F or 10.9°C) over 66,300 ft (20.2 km) flowline length is less than the temperature drop (21.8°F or 12.1°C) across 4,600 ft (1,400 m) of riser. The U-value of the riser assumed here, 0.528 Btu/ft2.hr.°F (3.0 W/m2.K), is almost 5.5 times greater than the U-value of the flowline. Further reduction in the U-value of riser does not improve the temperature drop across the riser because the temperature drop is not due to heat loss to surroundings but is due to adiabatic gas expansion in the riser. As shown in this example, the temperature loss due to potential energy loss can vary from 40% to 60% of the overall temperature drop within a deepwater production system.

Assessment of thermal performance

As stated earlier, the design goal of a subsea production system is to achieve an arrival temperature at the destination process facilities which is above the hydrate formation temperature and/or WAT. This temperature should be at least greater than the hydrate formation temperature, plus an acceptable margin considering the operations over the entire field life. Depending upon the acceptance criteria and subsea flowline configuration, operators may select a system that is designed to provide fluid arrival temperatures greater than both the WAT and hydrate formation temperature. This in turn reduces, and sometimes eliminates, the need for continuous paraffin inhibitor injection and/or regular pigging to remove wax deposits from the internal walls of flowlines. This translates to higher capex and lower opex. Hence, to achieve a system with good insulation and minimal intervention, the balance between opex and capex must be investigated.

The goal for shut-in operations is to achieve a specified cool-down time before the flowline contents cool to the hydrate formation temperature at the shut-in pressure. Where long flowlines are used, the steady state heat loss of the flowline will tend to dominate the amount of insulation, or the U-value, required. Where relatively short flowlines are used, the cool-down time will dictate the required maximum U-value. Hence, the temperature margin utilized for the estimation of optimum U-value for steady state operations is critical and sometimes may need to be increased to meet cool-down time requirements.

The criteria for determining the cool-down time for deepwater production lines and risers include the following operational activity periods:

• The preparation time for intervention, which is the minimum time required by the operator without any action for remedy, or “No Touch Time”

• The minimum time required to inject chemicals primarily to downhole tubing, christmas tree, jumpers, and manifold piping for a safe re-start

• The minimum time required to displace flowline contents with crude oil or diesel

• A safety margin on the three activities above.

The total time for completion of all these activities should be considered in optimum cool-down time selection.

The opex and capex balance investigation should be conducted once the optimum U-value is concluded following the thermal assessment for steady state flow and shut-in operations. In some cases, however, a combination of insulation and chemical injection can result in a more economical and operations friendly solution.•